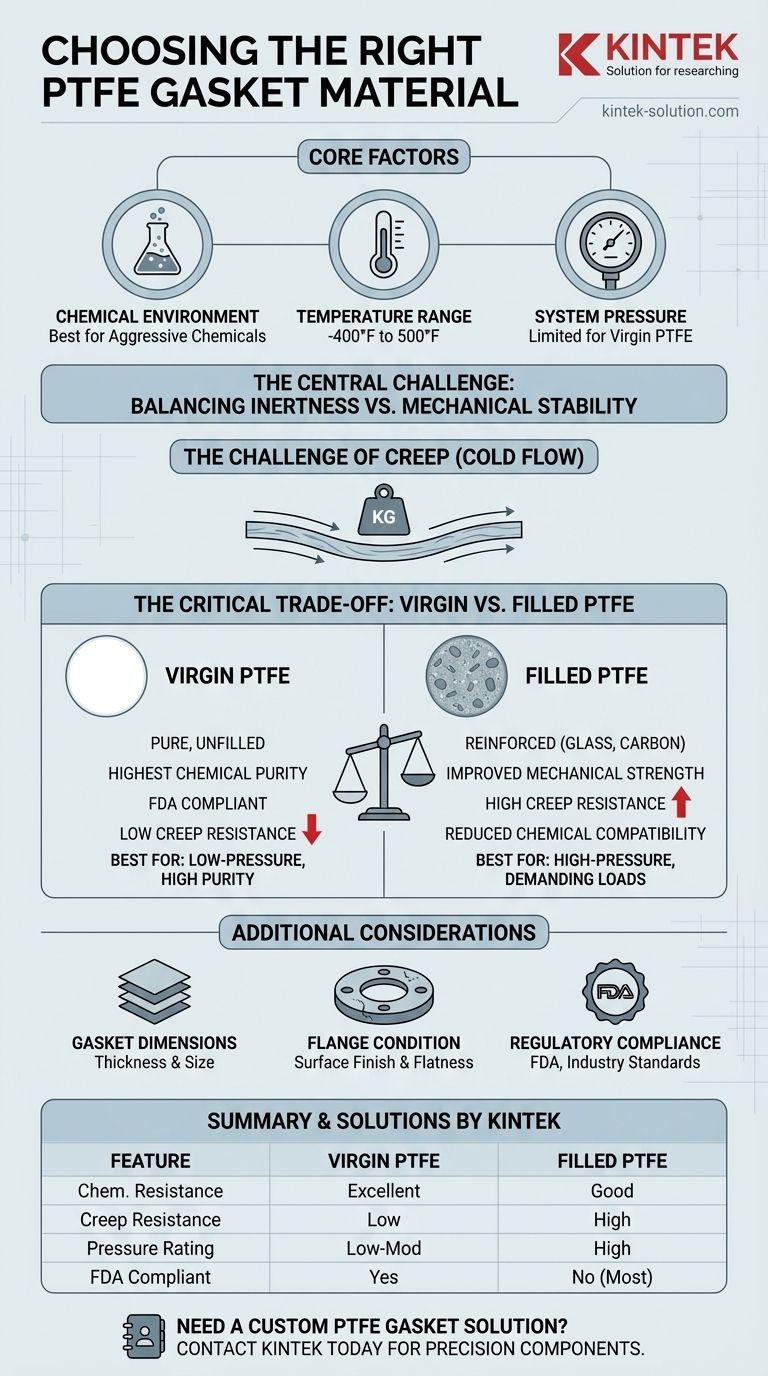

To select the right PTFE gasket, you must evaluate your application's specific operational demands. The most critical factors are the chemical environment the gasket will be exposed to, the minimum and maximum operating temperatures, and the system pressure it must withstand. These three elements form the foundation of a reliable material choice.

While pure PTFE offers unmatched chemical resistance and purity, it is mechanically weak and prone to deforming under load. The central challenge is balancing this chemical inertness against the mechanical stability required for your specific pressure and temperature conditions.

Analyzing Your Operating Environment

Every sealing application presents a unique set of environmental challenges. A precise understanding of these conditions is the first step toward selecting a gasket that will perform reliably and safely.

Chemical Compatibility: PTFE's Core Strength

Polytetrafluoroethylene (PTFE) is renowned for its exceptional chemical resistance. It is virtually inert to most industrial chemicals, including strong acids, alkalis, and organic solvents.

This makes it a default choice for aggressive chemical services where other materials would quickly degrade.

Temperature Range: Defining the Operational Window

PTFE functions effectively across an extremely broad temperature range, typically from -400°F to 500°F (-240°C to 260°C).

However, you must verify the material's suitability for your specific range. The mechanical properties of PTFE, particularly its resistance to deformation, decrease at higher temperatures.

Pressure Limitations: When Virgin PTFE Isn't Enough

The pressure of the system is a critical constraint. Standard, or "virgin," PTFE is a soft material that can be extruded or forced out of place under high pressures.

For applications exceeding moderate pressure ratings (e.g., above 150-300 psi), a standard PTFE gasket is likely to fail. In these cases, a reinforced or "filled" PTFE is necessary.

Understanding the Mechanical Demands

Beyond the core environmental factors, the physical and mechanical aspects of the joint dictate the gasket's success. This includes the condition of the sealing surfaces and the properties of the gasket itself.

Sealing Performance: The Ultimate Goal

A gasket's primary function is to create and maintain a seal, preventing leaks. All other factors—temperature, pressure, and mechanical strength—contribute to this single objective.

Effective sealing depends on the material's ability to conform to the flange surfaces and resist degradation over time.

Gasket Dimensions: The Role of Thickness and Size

The gasket's dimensions must be precise for the flange it will seal. Choosing the correct thickness is a careful balance.

A thicker gasket can better conform to and seal flanges that are warped, pitted, or uneven. However, it is also more susceptible to being pushed out of place.

A thinner gasket offers greater rigidity and blowout resistance but requires smoother, flatter flange surfaces to create an effective seal.

Flange Condition: The Overlooked Factor

The surface finish and flatness of your sealing flanges are just as important as the gasket material. No gasket can reliably seal a badly damaged or warped flange.

Always inspect the flange surfaces before installation to ensure they are clean and meet the required flatness for the gasket you are using.

The Critical Trade-off: Creep Resistance vs. Purity

The most significant challenge with PTFE is its tendency to deform under pressure over time. Understanding this trade-off is key to making an expert decision.

The Challenge of Cold Flow (Creep)

PTFE is susceptible to a phenomenon known as creep, or cold flow. This is the tendency of the material to slowly and permanently deform when subjected to a sustained compressive load, such as the bolt torque on a flange.

This deformation can lead to a loss of bolt load and, eventually, a leak. The risk of creep increases significantly with higher temperatures and pressures.

The Solution: Filled vs. Virgin PTFE

To combat creep, manufacturers add filler materials to the PTFE resin. These fillers dramatically improve the gasket's mechanical properties.

- Virgin PTFE: Pure, unfilled material. It offers the highest chemical purity and complies with FDA standards, but has the lowest resistance to creep.

- Filled PTFE: Contains additives like glass, carbon, or silica. These materials significantly increase compressive strength and creep resistance, making them suitable for higher pressure and temperature applications. The trade-off is a slight reduction in chemical compatibility and the loss of FDA compliance for some fillers.

Navigating Regulatory and Industry Standards

For certain industries, material selection is governed by strict regulations to ensure safety and prevent contamination.

Compliance for Sensitive Applications (FDA)

In the food, beverage, and pharmaceutical industries, any material in contact with the product must meet specific standards.

Virgin PTFE is compliant with FDA regulations, making it a common choice for these pure applications where its mechanical limitations are acceptable.

Making the Right Choice for Your Application

Your final decision should be a direct response to the primary demands of your system.

- If your primary focus is extreme chemical resistance and purity: Choose a virgin PTFE gasket, ensuring your pressure and temperature are well within its mechanical limits.

- If your primary focus is sealing at high pressures or temperatures: Select a filled PTFE, such as glass- or carbon-filled, to gain the necessary creep resistance.

- If your primary focus is sealing older or uneven flange surfaces: Opt for a slightly thicker or more conformable style of PTFE gasket that can fill surface imperfections.

Ultimately, choosing the right gasket is about matching the unique strengths of a specific PTFE material to the precise demands of your application.

Summary Table:

| Key Selection Factor | Virgin PTFE | Filled PTFE |

|---|---|---|

| Chemical Resistance | Excellent (Virtually Inert) | Good (Slightly Reduced) |

| Temperature Range | -400°F to 500°F (-240°C to 260°C) | -400°F to 500°F (-240°C to 260°C) |

| Pressure Rating | Low to Moderate (Below ~150-300 psi) | High (Improved Creep Resistance) |

| Creep/Cold Flow Resistance | Low | High |

| FDA Compliance | Yes | No (for most fillers) |

| Best For | Extreme chemical purity, low-pressure applications | High-pressure/temperature, demanding mechanical applications |

Need a Custom PTFE Gasket Solution?

Selecting the right material is critical for safety and performance. KINTEK specializes in manufacturing high-precision PTFE components, including custom gaskets, seals, and liners.

We help engineers in the semiconductor, medical, laboratory, and industrial sectors solve complex sealing challenges by balancing chemical resistance with mechanical strength. Whether you need FDA-compliant virgin PTFE for purity or reinforced filled PTFE for high-pressure durability, our expertise ensures a perfect match for your application.

We offer:

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Expertise: Guidance on virgin vs. filled PTFE for your specific temperature, pressure, and chemical environment.

- Precision Production: Components manufactured to exact specifications for a reliable, leak-free seal.

Let us help you ensure a perfect seal. Contact KINTEK today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability