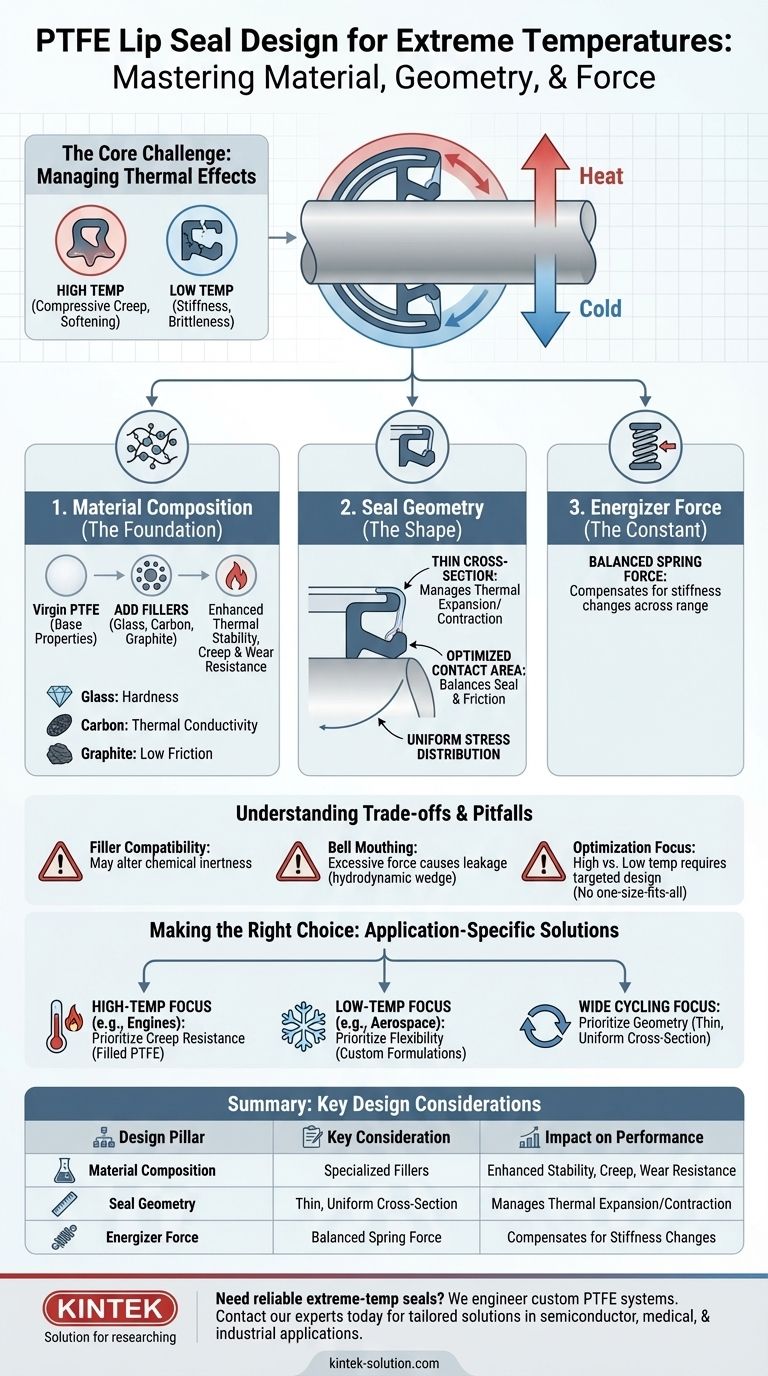

For extreme temperature applications, a successful PTFE lip seal design hinges on three interdependent factors: a precisely formulated material composition to resist thermal effects, an optimized seal geometry to manage physical expansion and contraction, and a balanced energizer force to maintain a consistent seal across the entire temperature range.

The core principle is that a PTFE seal for extreme temperatures is not just a component, but a carefully engineered system. Success depends on holistically balancing the material, its physical shape, and the spring that energizes it to work in concert against thermal stress.

The Core Challenge: Managing Thermal Effects

Polytetrafluoroethylene (PTFE) is known for its wide operating temperature range, typically from -53°C to 232°C (-65°F to 450°F). However, extreme temperatures introduce significant stresses that a standard seal design cannot handle.

The Impact of High Temperatures

At elevated temperatures, materials can soften, degrade, and experience compressive creep. This is a slow deformation under a constant load, which can cause the seal lip to lose its designed contact pattern and fail.

The Impact of Low Temperatures

In cryogenic or sub-zero conditions, materials become less flexible and more brittle. A seal must retain enough elasticity to conform to the shaft surface, and the energizer must provide enough force to compensate for the material's increased stiffness.

Critical Design Pillar 1: Material Composition

The foundation of a high-performance seal is its material. While standard PTFE is capable, specialized formulations are necessary for thermal extremes.

Base PTFE and Its Limits

Virgin PTFE provides excellent low-friction properties and chemical resistance, but it can be susceptible to creep and wear in demanding applications. Its properties must be enhanced for thermal stability.

The Role of Fillers

To improve performance, fillers are blended with the base PTFE. These additives dramatically improve key properties for thermal resilience.

Common fillers include glass, carbon, and graphite. They enhance thermal conductivity, increase hardness, and significantly improve resistance to wear and compressive creep at high temperatures.

Custom Formulations for Specific Extremes

Seal manufacturers often develop custom polymer blends. These formulations can be optimized to maintain flexibility at cryogenic temperatures or to maximize structural integrity and degradation resistance in high-heat environments like automotive engines.

Critical Design Pillar 2: Seal Geometry

How the seal is shaped is just as critical as the material it's made from. The geometry must be designed to anticipate and mitigate the effects of temperature change.

The Importance of a Thin Cross-Section

PTFE has a high flexural modulus. A uniformly thin element cross-section is a key design feature that helps compensate for this stiffness.

This thin profile also minimizes the effects of thermal expansion and contraction, helping to maintain a consistent and controlled contact pattern on the shaft.

Optimizing the Lip Contact Area

The contact area between the seal lip and the shaft is a delicate balance. It must be sufficient to create a reliable seal without generating excessive friction or heat.

Accommodating Expansion and Contraction

The overall seal geometry must be designed to distribute stress evenly during thermal cycling. This prevents localized stress points that could lead to premature failure or creep.

Understanding the Trade-offs and Pitfalls

Specifying a seal for extreme temperatures is not without its challenges. Understanding the potential downsides of certain design choices is crucial for avoiding failure.

Filler Materials vs. Chemical Resistance

While fillers dramatically improve thermal and wear properties, they can sometimes slightly alter the broad chemical inertness of pure PTFE. The media being sealed must be compatible with both the PTFE and the specific filler material used.

The "Bell Mouthing" Phenomenon

Applying too much energizer force or designing an overly wide contact patch can cause the seal lip to deform into a "bell" shape. This bell mouthing can create a hydrodynamic wedge that actually pumps fluid past the seal, causing high leakage rates.

High vs. Low Temperature Optimization

A material blend and geometry optimized for a high-heat industrial gearbox will not be the ideal choice for a cryogenic aerospace application. Each extreme requires a targeted design, and a "one-size-fits-all" approach often leads to compromise and failure.

Making the Right Choice for Your Application

To ensure reliability, your design considerations must be aligned with the specific thermal challenges of your environment.

- If your primary focus is high-temperature environments (e.g., engines, chemical processing): Specify a filled PTFE grade with carbon or glass to maximize creep resistance and thermal stability.

- If your primary focus is cryogenic or low-temperature environments (e.g., aerospace): Prioritize material formulations that maintain excellent flexibility and an energizer design that provides consistent force as the lip stiffens.

- If your primary focus is wide temperature cycling: Emphasize a seal geometry with a thin, uniform cross-section to accommodate repeated expansion and contraction without losing its sealing integrity.

Ultimately, a systematic approach that considers the material, geometry, and energizer as a single, integrated system is the key to achieving reliable sealing in the most demanding thermal environments.

Summary Table:

| Design Pillar | Key Consideration | Impact on Performance |

|---|---|---|

| Material Composition | Use of specialized fillers (glass, carbon, graphite) | Enhances thermal stability, creep resistance, and wear resistance |

| Seal Geometry | Thin, uniform cross-section | Manages thermal expansion/contraction and maintains contact pattern |

| Energizer Force | Balanced spring force | Compensates for material stiffness changes across temperature range |

Need a PTFE lip seal that performs reliably in extreme temperatures? At KINTEK, we engineer custom PTFE seals (including lip seals, liners, and labware) as integrated systems. Our expertise in material science and precision manufacturing ensures your seals are optimized for thermal extremes in semiconductor, medical, laboratory, and industrial applications—from prototypes to high-volume orders. Contact our experts today to discuss your specific temperature challenges and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications