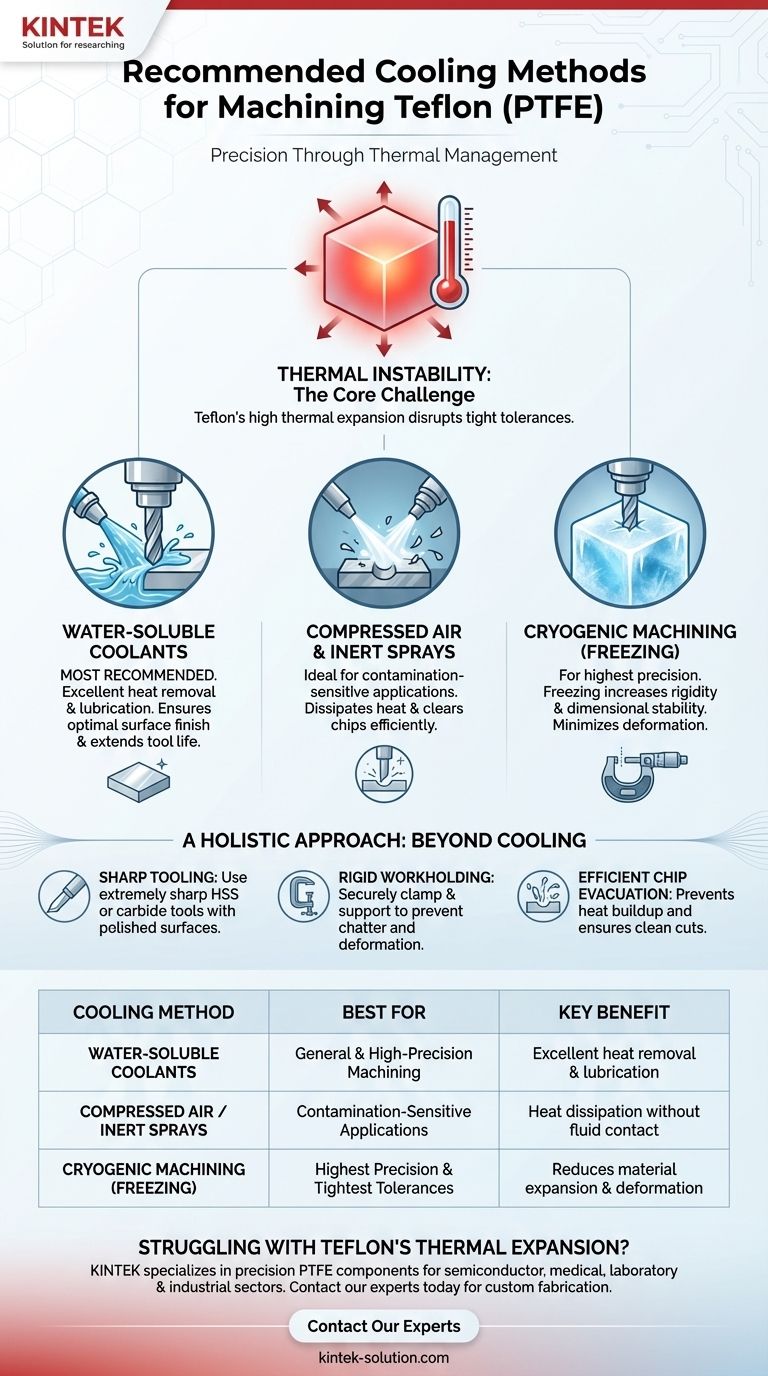

The most recommended cooling methods for machining Teflon (PTFE) are water-soluble coolants, compressed air, and chemically inert sprays. These methods are not merely suggestions but are critical for managing the material's extreme thermal expansion, which is the primary obstacle to achieving tight tolerances.

The core challenge in machining Teflon isn't its hardness but its thermal instability. Effective cooling is part of a larger strategy that must also include exceptionally sharp tooling and rigid workholding to prevent the material from deforming, warping, or expanding beyond specification.

Why Cooling is Non-Negotiable for Teflon

Teflon’s unique properties make it easy to cut but difficult to machine accurately. Heat is the primary enemy of precision in this process.

The Challenge of High Thermal Expansion

Teflon has a very high coefficient of thermal expansion. Even a small increase in temperature from cutting friction will cause the material to expand significantly.

This expansion makes holding tight tolerances nearly impossible, as the part will measure differently when warm than it does after it has cooled to a stable temperature.

Preventing Material Warping and Stress

The material's inherent softness, combined with heat generation, can lead to warping and the introduction of internal stresses.

Effective cooling maintains a stable temperature, preventing the workpiece from deforming under the pressure and heat of the cutting tool.

Ensuring a Quality Surface Finish

Excessive heat can cause the material to become gummy, leading to a poor surface finish and material buildup on the cutting tool.

A consistent cooling stream helps produce a clean, smooth cut and prolongs the life of your tools by reducing friction.

Recommended Cooling Strategies in Detail

The right cooling method depends on your specific application, but all aim to remove heat efficiently at the point of contact.

Water-Soluble Coolants

This is the most common and highly recommended method. A flood of non-aromatic, water-soluble coolant provides excellent heat removal and lubrication.

This approach results in optimal surface finishes and extends tool life by minimizing friction between the tool and the workpiece.

Compressed Air and Inert Sprays

For applications where liquid coolants could cause contamination, a constant stream of compressed air or a chemically inert spray can be effective.

These methods focus purely on dissipating heat and clearing chips away from the cutting zone, which also helps reduce friction.

Cryogenic Machining (Freezing)

For parts requiring the highest precision, temporarily freezing the Teflon before and during machining is an advanced technique.

Freezing makes the material more rigid and dimensionally stable, significantly reducing its tendency to deform or expand during the cutting process.

Beyond Cooling: A Holistic Approach to Machining Teflon

Cooling is a critical piece of the puzzle, but it cannot compensate for poor practices in other areas. Success requires a systematic approach.

The Critical Role of Tool Selection

Dull tools generate excess friction and heat, undermining any cooling strategy. Use extremely sharp high-speed steel or cemented carbide tools.

Tools with highly polished surfaces and positive rake angles are essential. They create a shearing action that cuts cleanly and generates less heat, reducing the burden on your cooling system.

The Importance of Rigid Workholding

Teflon's softness makes it highly susceptible to deformation and vibration if not secured properly.

Ensure the workpiece is securely clamped and fully supported to prevent chatter, which can ruin surface finish and dimensional accuracy.

Managing Chip Evacuation

Efficient chip removal is crucial. Chips left in the cutting area can generate additional friction and heat.

Choose tools designed for excellent chip clearance, and ensure your coolant or air stream effectively evacuates chips from the workpiece.

Understanding the Trade-offs and Pitfalls

Achieving success with Teflon means being aware of the common failure points that even experienced machinists can encounter.

Pitfall: Over-reliance on Cooling

Cooling cannot fix a bad setup. If you are using dull tools or the workpiece is vibrating, no amount of coolant will produce a good part.

Pitfall: Ignoring Material Creep

Teflon is prone to "stress creep," meaning it can slowly deform over time under pressure. This is separate from thermal expansion.

Ensure your workholding provides support without applying excessive clamping force that could cause the part to deform after it is removed from the machine.

Pitfall: Unbalanced Part Shapes

Due to its softness and high thermal expansion, machining features on only one side of a part can cause it to warp as heat and stress are introduced unevenly. Plan your toolpaths accordingly.

Making the Right Choice for Your Goal

Select your strategy based on the final requirements of your component.

- If your primary focus is the highest precision and tightest tolerances: Combine a flood of water-soluble coolant with exceptionally sharp, polished carbide tooling. Consider cryogenic freezing for critical applications.

- If your primary focus is general-purpose machining: Water-soluble coolants or a strong, continuous blast of compressed air will be sufficient when paired with sharp tools and proper workholding.

- If your primary focus is preventing fluid contamination: Use clean, dry compressed air or a chemically inert spray as your sole cooling method.

Ultimately, successful Teflon machining is achieved by treating heat as the primary problem and implementing a system of sharp tools, rigid support, and constant cooling to manage it.

Summary Table:

| Cooling Method | Best For | Key Benefit |

|---|---|---|

| Water-Soluble Coolants | General & High-Precision Machining | Excellent heat removal & lubrication |

| Compressed Air / Inert Sprays | Contamination-Sensitive Applications | Heat dissipation without fluid contact |

| Cryogenic Machining (Freezing) | Highest Precision & Tightest Tolerances | Reduces material expansion & deformation |

Struggling with Teflon's thermal expansion during machining? KINTEK specializes in precision PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts meet the tightest tolerances. Let us help you solve your most challenging machining problems. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments