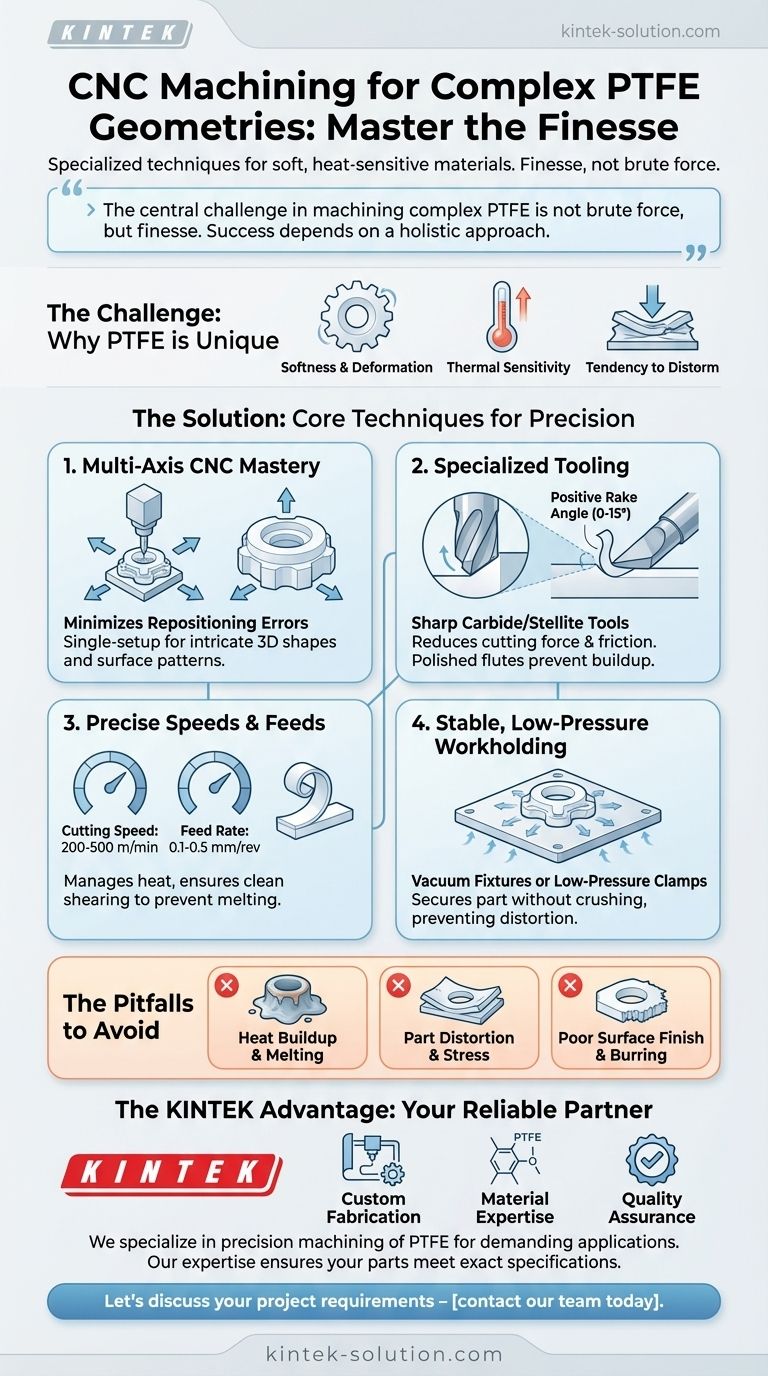

Machining complex PTFE geometries requires a specialized system of techniques focused on managing the material's unique softness, thermal sensitivity, and tendency to deform under pressure. The core methods involve using multi-axis CNC machines to minimize part handling, employing extremely sharp carbide or stellite tools, maintaining precise speeds and feeds to prevent melting, and utilizing stable workholding like vacuum fixtures to secure the part without distortion.

The central challenge in machining complex PTFE is not brute force, but finesse. Success depends on a holistic approach that prioritizes minimizing cutting forces, managing heat at the cutting edge, and preventing any deformation of the workpiece throughout the entire process.

The Foundation: Why Multi-Axis Machining is Crucial

Polytetrafluoroethylene (PTFE) is a uniquely challenging material due to its low mechanical strength and high thermal expansion. For complex parts, the choice of machine technology is the first and most critical decision.

Minimizing Repositioning Errors

Multi-axis CNC machines, such as 5-axis mills, are indispensable for complex geometries. They allow the cutting tool to approach the workpiece from multiple angles in a single setup.

This single-setup approach is vital for PTFE. Every time a soft part is unclamped and repositioned, the risk of introducing geometric errors, distortion, or surface marks increases significantly.

Enabling Intricate Operations

Different CNC operations are used to create specific features on PTFE parts.

- CNC Milling: This is used to create complex three-dimensional shapes, pockets, and intricate surface patterns.

- CNC Turning: This is ideal for producing cylindrical components like seals, rings, and shafts with high precision.

- Drilling and Tapping: This creates precise holes and internal threads, though it requires sharp tools and careful chip removal to avoid melting the material.

Critical Tooling and Cutting Parameters

The interface between the tool and the material is where most failures occur when machining PTFE. The right tool and settings prevent tearing, melting, and burring.

Tool Material and Geometry

The ideal tool for PTFE must be exceptionally sharp and wear-resistant.

- Tool Material: Carbide-tipped or Stellite-tipped tools are preferred. Their ability to hold a razor-sharp edge minimizes friction and reduces the heat generated during cutting.

- Tool Geometry: Tools should have a positive top rake (between 0 and 15 degrees) to reduce cutting forces. They should also be highly polished with single or double flutes to facilitate clean chip evacuation and prevent material buildup.

Dialing in Speeds and Feeds

Unlike metals, where higher forces are common, PTFE requires a light touch. The goal is to shear the material cleanly rather than push it.

- Cutting Speed: A relatively high cutting speed, typically between 200–500 m/min, helps ensure a clean cut.

- Feed Rate: A controlled feed rate of 0.1–0.5 mm/rev prevents the tool from pushing and deforming the material, which would compromise dimensional accuracy.

Understanding the Trade-offs and Pitfalls

Successfully machining PTFE involves anticipating its failure modes. A lack of attention to its specific properties is the primary source of error.

Heat Buildup and Material Integrity

The greatest enemy of PTFE machining is heat. Excessive friction from a dull tool or incorrect parameters will cause the material to melt and gum up, rather than cut cleanly. This results in a poor surface finish and dimensional inaccuracy. Regularly resharpening or replacing tools is not optional; it is a core part of the process.

Part Distortion and Internal Stress

PTFE's softness makes it highly susceptible to distortion. Overtightening a standard vise will crush the part, while excessive cutting force can cause the part to flex away from the tool. This is why stable, low-pressure workholding is non-negotiable for achieving tight tolerances.

Poor Surface Finish and Burring

Burrs on PTFE parts are a common sign of a suboptimal process. They are typically caused by a dull cutting edge that tears the material instead of shearing it. Using sharp, polished tools and optimized cutting parameters is the only way to achieve a clean, burr-free finish directly from the machine.

Making the Right Choice for Your Goal

To ensure your complex PTFE components are machined correctly, align your strategy and vendor selection with your project's primary objective.

- If your primary focus is prototyping a new, complex design: Prioritize a service provider with documented experience in PTFE and access to high-precision 5-axis CNC machines.

- If your primary focus is high-volume production with tight tolerances: Emphasize process control, including repeatable workholding solutions and a strict tool maintenance or replacement schedule.

- If your primary focus is achieving aerospace or medical-grade quality: Verify that your machining partner holds relevant industry certifications (e.g., ISO 9001, AS9100) that demonstrate a commitment to quality management.

By understanding these principles of control, you can confidently specify and procure complex PTFE components that meet your exact requirements.

Summary Table:

| Technique | Key Consideration | Benefit |

|---|---|---|

| Multi-Axis Machining | Single setup for complex shapes | Minimizes repositioning errors and part distortion |

| Specialized Tooling | Sharp carbide/stellite tools with positive rake | Reduces cutting force and prevents material tearing |

| Precise Speeds & Feeds | High speed (200-500 m/min), controlled feed | Manages heat and ensures clean shearing of material |

| Stable Workholding | Vacuum fixtures or low-pressure clamps | Secures soft PTFE without causing deformation |

Need a reliable partner for your complex PTFE components?

At KINTEK, we specialize in precision machining of PTFE for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in multi-axis CNC techniques, combined with strict process controls, ensures your prototypes and high-volume orders meet exact specifications without compromise.

We provide:

- Custom Fabrication: From initial prototypes to large-scale production runs.

- Material Expertise: In-depth knowledge of machining PTFE and other high-performance polymers.

- Quality Assurance: Adherence to industry standards for consistent, reliable results.

Let's discuss your project requirements – contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications