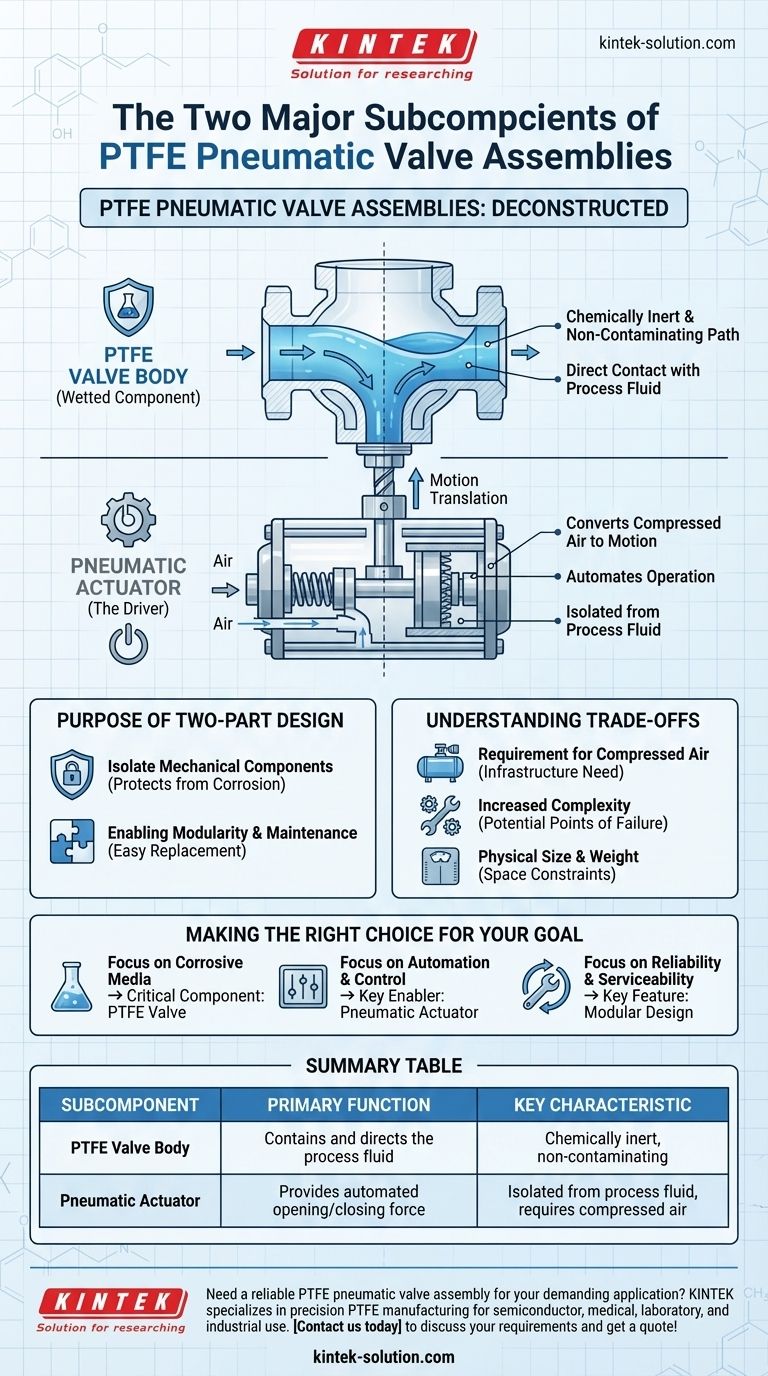

At its core, a PTFE pneumatic valve assembly consists of two distinct and essential subcomponents: the PTFE valve body and the pneumatic actuator. The valve is the fluid-handling component responsible for chemical resistance, while the actuator is the mechanical driver that automates its operation.

The fundamental design principle is the separation of duties: the inert PTFE valve contains and directs the corrosive media, while the external pneumatic actuator provides the automated force needed to open and close it, ensuring the mechanical components are never exposed to the harsh process fluid.

Deconstructing the Assembly

To understand how these systems function in demanding environments, it's crucial to analyze each major component's specific role.

The PTFE Valve: The Wetted Component

The PTFE valve is the part of the assembly that comes into direct contact with the process fluid. It is often referred to as the "wetted" component for this reason.

Its primary function is to provide an exceptionally chemically inert and non-contaminating path for aggressive or high-purity media. The material properties of PTFE (polytetrafluoroethylene) make it the ideal choice for this role.

The Pneumatic Actuator: The Driver

The pneumatic actuator is the "engine" of the assembly. It converts the energy from compressed air into the physical motion required to operate the valve.

This component is responsible for the automation of the valve. It receives a pneumatic signal (a pulse of compressed air) and uses it to move a piston or diaphragm, which in turn opens or closes the PTFE valve mechanism it is mounted to.

The Critical Interface

The two components are joined at a critical interface, typically a standardized mounting pattern. The actuator's stem or shaft connects directly to the valve's internal mechanism.

This connection allows the linear or rotary motion generated by the actuator to be precisely translated into the desired action of the valve, such as lifting a diaphragm or turning a ball.

The Purpose of the Two-Part Design

The separation of the valve and actuator is a deliberate engineering choice driven by the need for reliability and safety in corrosive environments.

Isolating Mechanical Components

The most important reason for this design is to isolate the actuator's sensitive mechanical parts from the harsh process fluid. The actuator contains seals, springs, and pistons that would quickly corrode and fail if exposed to acids or other aggressive chemicals.

By keeping the fluid path entirely within the inert PTFE valve body, the design ensures the longevity and reliability of the automation components.

Enabling Modularity and Maintenance

This two-part structure creates a modular system. You can select an actuator with specific features (like fail-safe open or fail-safe closed) and pair it with the appropriate PTFE valve body for your chemical application.

This modularity also simplifies maintenance. If an actuator fails, it can be replaced without disturbing the process piping or exposing the fluid line to the atmosphere.

Understanding the Trade-offs

While highly effective, this assembly design has inherent characteristics that must be considered.

Requirement for Compressed Air

The most obvious requirement is the need for a reliable source of clean, dry compressed air. This infrastructure is essential for the actuator to function and must be factored into the total system design and cost.

Increased Complexity

Compared to a simple manual valve, a pneumatic assembly has more components. The actuator, air lines, and control solenoids introduce additional points of potential failure that require proper installation and periodic inspection.

Physical Size and Weight

Pneumatic actuators add considerable bulk and weight to the valve. This can be a significant factor in applications with tight space constraints or where structural support is limited.

Making the Right Choice for Your Goal

Understanding this fundamental two-part structure helps in specifying the correct assembly for your specific process need.

- If your primary focus is handling highly corrosive media: Your critical component is the PTFE valve, and you must ensure its material composition is compatible with your process fluid.

- If your primary focus is process automation and control: The pneumatic actuator is the key enabler, and its specifications (actuation speed, failure mode, control signal) are your main concern.

- If your primary focus is system reliability and serviceability: The modular design itself is the key feature, allowing for easier maintenance and component replacement over the system's life.

Recognizing the distinct roles of the valve and the actuator is the first step toward building a robust and reliable automated fluid handling system.

Summary Table:

| Subcomponent | Primary Function | Key Characteristic |

|---|---|---|

| PTFE Valve Body | Contains and directs the process fluid | Chemically inert, non-contaminating |

| Pneumatic Actuator | Provides automated opening/closing force | Isolated from process fluid, requires compressed air |

Need a reliable PTFE pneumatic valve assembly for your demanding application?

KINTEK specializes in the precision manufacturing of PTFE components, including seals, liners, and custom valve bodies for semiconductor, medical, laboratory, and industrial use. Our expertise ensures your automated fluid handling system is built for maximum chemical resistance and long-term reliability, from prototype to high-volume production.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications