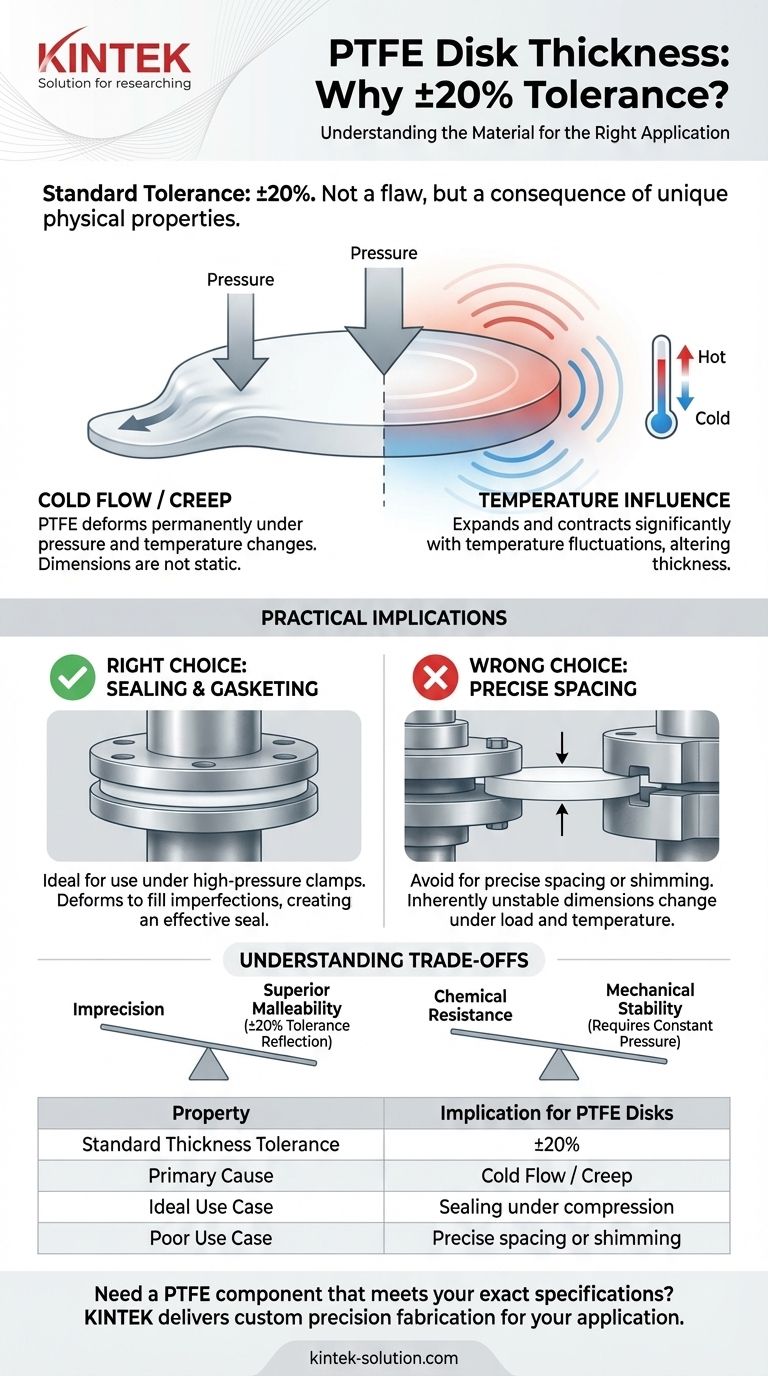

The standard thickness tolerance for PTFE disks is ±20%. This unusually high tolerance is not an indicator of poor manufacturing quality but is a direct consequence of the unique physical properties of Polytetrafluoroethylene (PTFE) itself.

The core issue is that PTFE is a soft material subject to "cold flow," meaning it deforms permanently under pressure and temperature changes. Therefore, its value is in its ability to be compressed into a seal, not in its use as a precise, dimensionally stable spacer.

Why Such a High Tolerance? The Nature of PTFE

The ±20% tolerance specification is rooted in the fundamental characteristics of the material. Understanding these properties is crucial to using PTFE disks correctly.

Understanding 'Cold Flow' and Creep

PTFE is a fluoropolymer plastic known for its softness and malleability. It exhibits a property known as cold flow, or creep.

This means that even at room temperature, the material will slowly deform and "flow" away from a point of pressure over time. Its dimensions are not static.

Because of this, PTFE is not intended to hold a precise thickness in the same way a metal or rigid plastic shim would.

The Impact of Pressure

The tendency for PTFE to cold flow is precisely why it excels in certain applications. When used with a high-pressure clamp, the material deforms to fill microscopic imperfections in mating surfaces.

This creates an extremely effective, gas-tight or liquid-tight seal. The initial thickness is less important than its ability to conform to the required shape under load.

The Influence of Temperature

PTFE is also sensitive to temperature fluctuations. It has a relatively high coefficient of thermal expansion.

As temperatures change, a PTFE disk will expand or contract, altering its thickness. This makes it unsuitable for applications requiring stable dimensions across a wide temperature range, especially without constant clamping pressure.

The Practical Implications for Application Design

Given these properties, the choice to use a PTFE disk depends entirely on the engineering goal. Its high tolerance makes it an excellent choice for some tasks and a poor choice for others.

When PTFE is the Right Choice

PTFE disks are ideal for gasketing and sealing applications. Their ability to flow and create a perfect seal under compression is their primary advantage.

They are used almost exclusively in situations where they can be compressed by flanges, fittings, or clamps.

When PTFE is the Wrong Choice

Avoid using PTFE disks for any application that requires precise spacing or shimming. Its dimensions are inherently unstable and will change under load and with temperature.

For these tasks, a more rigid and dimensionally stable material, such as stainless steel, aluminum, or a hard engineering plastic like PEEK, would be a far better choice.

Understanding the Trade-offs

Using PTFE effectively means accepting a specific set of trade-offs. The material's greatest strength is also the source of its primary limitation.

Imprecision vs. Malleability

You are trading dimensional precision for superior malleability and sealing capability. The ±20% tolerance is a reflection of this design intent.

Chemical Resistance vs. Mechanical Stability

While PTFE offers exceptional chemical inertness, it lacks the mechanical stability of other materials. You gain resistance to nearly all chemicals at the cost of dimensional rigidity.

Environmental Sensitivity

The material's performance is highly dependent on its operating environment. Constant pressure is a necessity, and significant temperature swings can compromise its function if the application is not designed to accommodate them.

Making the Right Choice for Your Application

To determine if a PTFE disk is appropriate, analyze the primary requirement of your design.

- If your primary focus is creating a high-pressure seal: PTFE is an excellent choice, as its ability to flow and deform under compression is its main strength.

- If your primary focus is precise, static spacing: You must avoid PTFE and select a dimensionally stable material like metal or a rigid polymer.

- If your application involves significant temperature changes: Use PTFE with caution, ensuring it remains under constant clamping pressure to maintain a reliable seal.

Ultimately, understanding PTFE's inherent properties is the key to leveraging its unique strengths for the right application.

Summary Table:

| Property | Implication for PTFE Disks |

|---|---|

| Standard Thickness Tolerance | ±20% |

| Primary Cause | Cold Flow / Creep |

| Ideal Use Case | Sealing under compression |

| Poor Use Case | Precise spacing or shimming |

Need a PTFE component that meets your exact specifications?

At KINTEK, we understand the critical balance between material properties and application requirements. Our expertise in precision manufacturing allows us to produce high-quality PTFE seals, liners, and labware that perform reliably.

Whether you need custom fabrication for a unique prototype or high-volume orders for the semiconductor, medical, or industrial sectors, we prioritize delivering components that fit your application perfectly.

Contact our experts today to discuss your project and discover how we can provide a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining