At its core, the self-lubricating property of Polytetrafluoroethylene (PTFE) rod stems from its exceptionally low coefficient of friction, one of the lowest of any solid material. This inherent "slipperiness" allows it to drastically reduce friction and wear between moving parts without requiring any external oils or greases. This makes it a preferred material for components like bearings, bushings, and seals where smooth, low-maintenance operation is critical.

The essential takeaway is that PTFE's unique molecular structure creates a waxy, non-stick surface that functions as a built-in lubricant. This simplifies mechanical design, reduces long-term maintenance, and enables reliable operation in environments where traditional lubrication is impractical or forbidden.

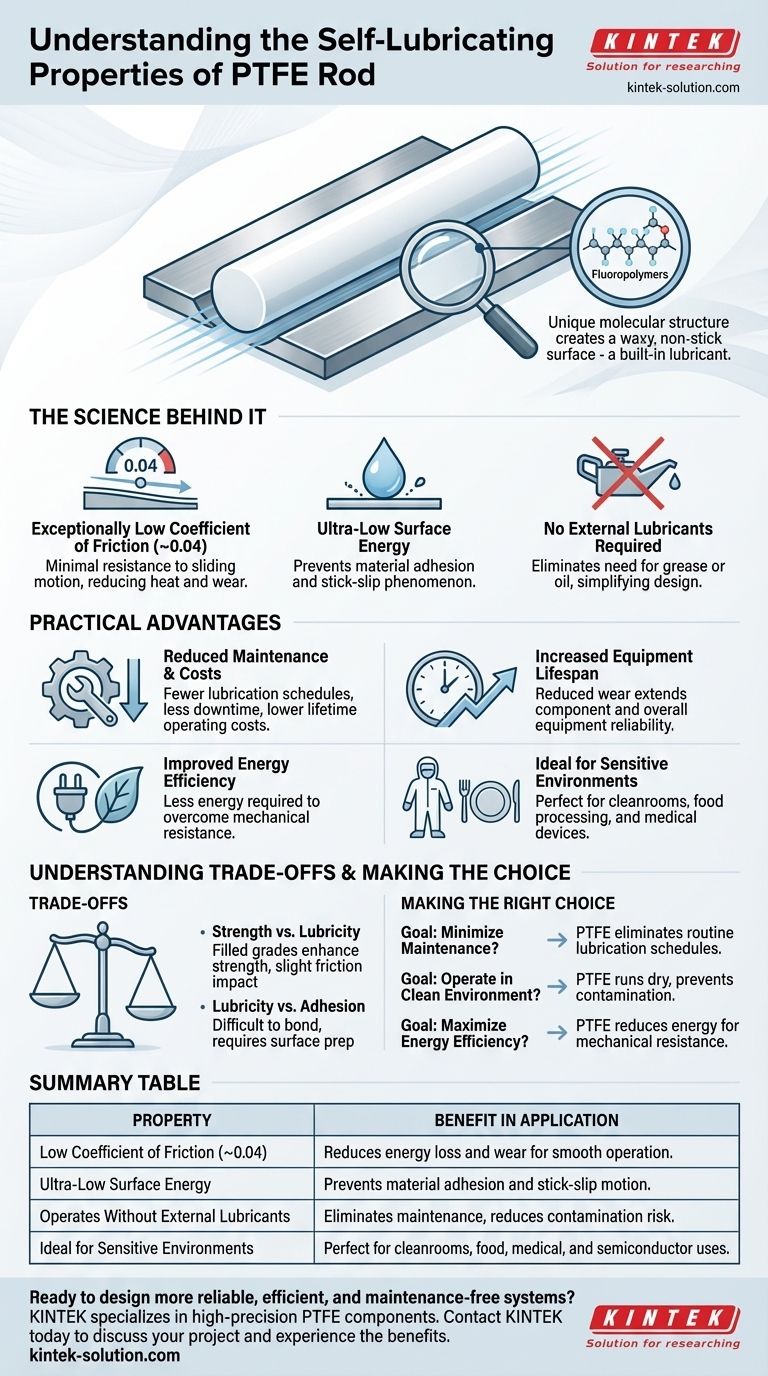

The Science Behind PTFE's Low Friction

The term "self-lubricating" is not just a marketing claim; it is a direct result of PTFE's fundamental material properties. Understanding these properties explains why it performs so well in mechanical applications.

An Exceptionally Low Coefficient of Friction

PTFE has an incredibly low coefficient of friction, measured at approximately 0.04. This value signifies an extremely low resistance to sliding motion.

When two surfaces slide against each other, friction generates heat and causes wear. PTFE's molecular structure minimizes this resistance, allowing components to move smoothly with minimal energy loss.

The Role of Surface Energy

The material has an ultra-low surface energy, which is why it is famous for its non-stick properties in applications like cookware.

In mechanical systems, this means other materials do not easily adhere to its surface. This prevents the "stick-slip" phenomenon that can cause jerky motion and premature wear in other materials.

Eliminating External Lubricants

Because friction is already so low, there is no need to add external lubricants like grease or oil.

This property is a significant advantage, as it removes the cost and labor of re-applying lubricants and eliminates a potential point of failure if lubrication runs dry.

Practical Advantages in Mechanical Systems

The inherent self-lubrication of PTFE translates directly into tangible benefits for equipment design, performance, and longevity.

Reduced Maintenance and Costs

The most immediate benefit is the reduction or complete elimination of routine lubrication schedules. This leads to less downtime for machinery and lower lifetime operating costs.

Increased Equipment Lifespan

By minimizing friction, PTFE directly reduces wear and tear on moving parts. Components made from or sliding against PTFE last longer, increasing the overall reliability and lifespan of the equipment.

Improved Energy Efficiency

Systems with PTFE components require less energy to overcome mechanical resistance. This results in more efficient operation and can lead to measurable energy savings over time.

Ideal for Contamination-Sensitive Environments

The ability to operate without oil or grease makes PTFE essential for specific industries. It is ideal for cleanroom environments, food processing machinery, and medical devices, where contamination from traditional lubricants is unacceptable.

Understanding the Trade-offs

While its self-lubricating nature is a powerful advantage, it is crucial to understand the context and potential misconceptions.

Strength vs. Lubricity

Pure, unmodified PTFE is relatively soft. While its lubricity is excellent, it can be prone to wear under very high mechanical loads or pressures. For this reason, filled grades of PTFE (which include additives like carbon or glass) are often used to enhance strength, though this can slightly alter its frictional properties.

Lubricity vs. Adhesion

The same low surface energy that makes PTFE slippery also makes it very difficult to bond to other materials. Using adhesives with PTFE requires specialized surface preparation, which must be considered during the design phase.

Clarifying "Pre-Lubricated" Products

Some products, like certain types of PTFE packing for seals, may be described as "pre-lubricated." This typically refers to a lubricant added during manufacturing to aid in installation and initial seating, not as a requirement for ongoing operation. The underlying material remains inherently self-lubricating.

Making the Right Choice for Your Goal

Selecting PTFE is a strategic decision based on the primary requirements of your application.

- If your primary focus is minimizing maintenance: PTFE is an outstanding choice because it eliminates the need for a routine lubrication schedule, reducing labor and downtime.

- If your primary focus is operating in a clean environment: PTFE is often the only viable option, as its ability to run completely dry prevents product contamination in food, medical, or semiconductor applications.

- If your primary focus is maximizing energy efficiency: PTFE's exceptionally low friction reduces the energy required to overcome mechanical resistance, making it a strong candidate for efficient system design.

Understanding that PTFE's self-lubricating property is an intrinsic material characteristic empowers you to design more reliable, efficient, and lower-maintenance mechanical systems.

Summary Table:

| Property | Benefit in Application |

|---|---|

| Low Coefficient of Friction (~0.04) | Reduces energy loss and wear for smooth operation. |

| Ultra-Low Surface Energy | Prevents material adhesion and stick-slip motion. |

| Operates Without External Lubricants | Eliminates maintenance, reduces contamination risk. |

| Ideal for Sensitive Environments | Perfect for cleanrooms, food, medical, and semiconductor uses. |

Ready to design more reliable, efficient, and maintenance-free systems?

KINTEK specializes in manufacturing high-precision PTFE components—including custom rods, seals, bushings, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the perfect self-lubricating solution for your application.

Contact KINTEK today to discuss your project and experience the benefits of our precision PTFE components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- How can users obtain customized PTFE gaskets and sheets? Get Precision Parts for Your Industry

- What are the advantages of PTFE piston rings and guide rings for dry-running applications? Boost Efficiency and Purity

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the disadvantages of mechanical seals with PTFE rings? Understanding the Risks of Creep and Thermal Instability

- What are the key properties of PTFE pipes? Unlock Unmatched Chemical & Thermal Resistance

- What industries commonly use PTFE expansion joints and why? Solve Critical Pipeline Challenges with PTFE

- What factors should be considered when choosing between bronze and PTFE bushings? A Guide to Optimal Bearing Performance