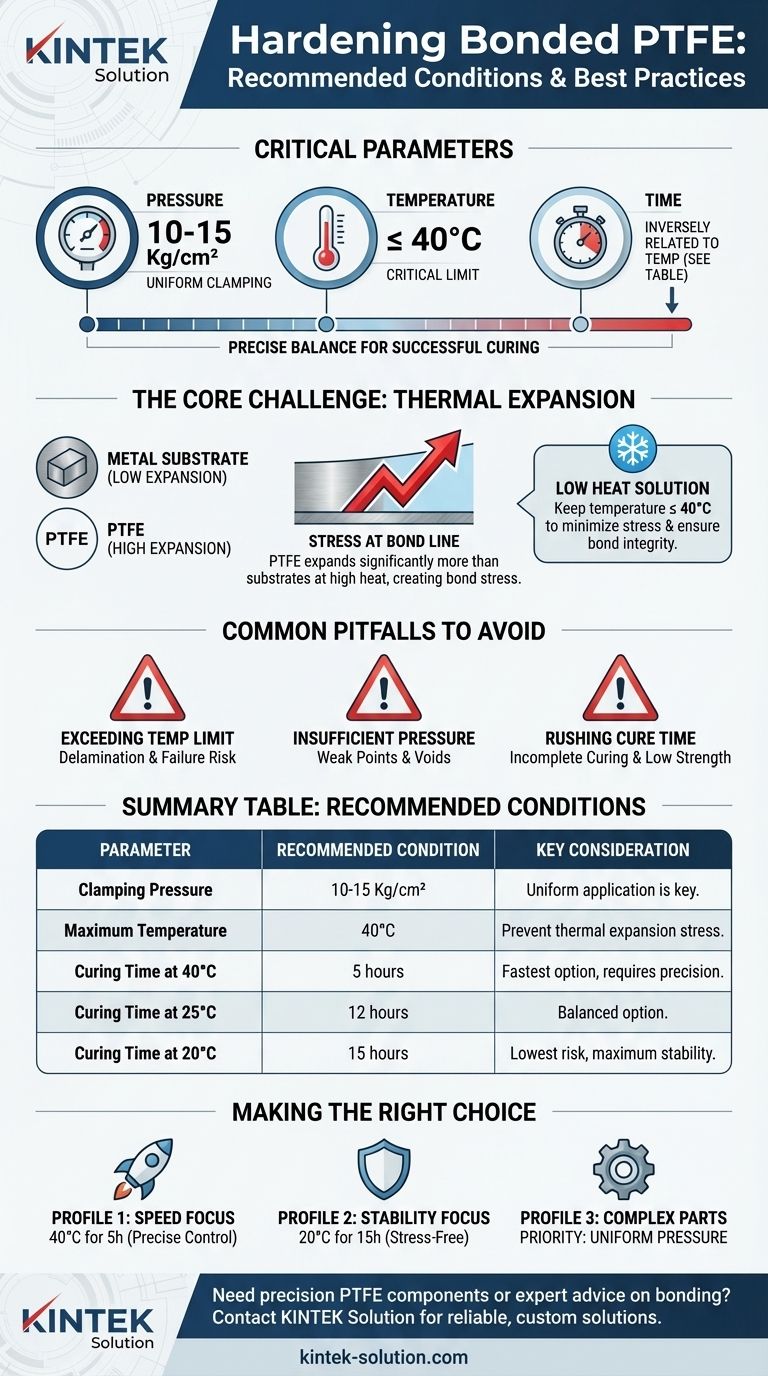

To successfully harden bonded PTFE, you must maintain a precise balance of temperature, pressure, and time. The recommended clamping pressure is 10-15 Kg/cm², and the curing temperature must not exceed 40°C. Hardening time is inversely related to temperature, requiring 5 hours at 40°C, 12 hours at 25°C, or 15 hours at 20°C.

The core challenge in hardening bonded PTFE is not just curing the adhesive, but managing the material's high rate of thermal expansion. Success depends on using low heat and consistent pressure to create a strong, stress-free bond that won't fail later.

The Critical Parameters for Hardening

To achieve a reliable bond, each parameter must be carefully controlled. These variables work together to ensure the adhesive cures completely without compromising the integrity of the assembly.

Temperature Control is Non-Negotiable

The single most critical rule is to keep the curing temperature at or below 40°C.

This strict limit is necessary because PTFE has a much higher coefficient of thermal expansion than the materials it is typically bonded to, such as metals. Exceeding this temperature causes the PTFE to expand significantly more than its substrate, creating immense stress at the bond line that can lead to immediate or future failure.

The Role of Consistent Clamping Pressure

A constant clamping pressure of 10-15 Kg/cm² must be applied uniformly across the entire bond surface.

This pressure ensures intimate contact between the PTFE, the adhesive, and the substrate. Without it, you risk voids or gaps in the bond, resulting in weak spots that will compromise the final assembly's strength and reliability.

The Time and Temperature Relationship

Curing time is directly dependent on the temperature you choose. The provided guidelines create a curing profile:

- At 20°C (68°F): 15 hours

- At 25°C (77°F): 12 hours

- At 40°C (104°F): 5 hours

Lower temperatures require longer times to allow the adhesive to fully cross-link and achieve maximum strength. While higher temperatures accelerate the cure, they also bring you closer to the critical thermal expansion threshold.

Understanding the Core Challenge: PTFE's Properties

The strict hardening parameters are a direct consequence of PTFE's inherent physical properties. Understanding this context is key to avoiding process failures.

Why Thermal Expansion Matters

Think of the bond line as a tug-of-war. As you heat the assembly, the PTFE expands rapidly while the metal substrate expands slowly. This mismatch pulls on the adhesive layer from opposite directions.

By keeping the temperature low, you minimize the intensity of this "tug-of-war," allowing the adhesive to cure in a low-stress environment.

Parallels from Machining PTFE

The same sensitivity to heat that governs bonding also dictates how PTFE is machined. Machinists must use low cutting speeds and coolants to prevent heat buildup.

Excessive heat during machining causes the material to expand and distort, making precision impossible. This principle reinforces why low-temperature curing is essential for maintaining dimensional stability and bond integrity.

Common Pitfalls to Avoid

Deviating from the recommended parameters can lead to bond failure. These are the most common mistakes.

Exceeding the Temperature Limit

This is the most frequent cause of failure. It creates excessive internal stress that can delaminate the bond during the cooling phase or, worse, create a latent defect that fails under operational load.

Insufficient or Uneven Pressure

Applying too little pressure or applying it unevenly results in an incomplete bond. Areas with poor contact will not adhere, creating weak points that can peel or separate over time.

Rushing the Cure Time

Cutting the hardening time short, even if the bond feels solid to the touch, is a critical error. The adhesive will not have fully cured, meaning it lacks its specified chemical resistance and mechanical strength.

Making the Right Choice for Your Goal

Use your project's primary driver to select the optimal curing profile.

- If your primary focus is speed: Cure at the maximum allowable temperature of 40°C for 5 hours, but ensure your equipment provides precise and stable temperature control.

- If your primary focus is maximum stability and minimal risk: Cure at a lower ambient temperature like 20°C for 15 hours to create the most stress-free bond possible.

- If you are bonding large or complex geometries: Prioritize uniform pressure distribution above all else, as this is the most common failure point for non-uniform parts.

Mastering these controlled conditions ensures you harness PTFE's exceptional properties without falling victim to its processing challenges.

Summary Table:

| Parameter | Recommended Condition | Key Consideration |

|---|---|---|

| Clamping Pressure | 10-15 Kg/cm² | Must be applied uniformly across the bond surface. |

| Maximum Temperature | 40°C | Critical to prevent stress from PTFE's high thermal expansion. |

| Curing Time at 40°C | 5 hours | Fastest option, requires precise temperature control. |

| Curing Time at 25°C | 12 hours | Balanced option for many applications. |

| Curing Time at 20°C | 15 hours | Lowest risk, creates the most stress-free bond. |

Need precision PTFE components or expert advice on bonding processes?

At KINTEK, we manufacture high-quality PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your components are designed and produced to meet the most demanding specifications, including successful bonding applications.

Contact our experts today to discuss how we can support your project with reliable PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining