At its core, carbon-filled PTFE is a composite material that enhances the performance of standard Polytetrafluoroethylene (PTFE) for demanding applications. By adding carbon as a filler, the material gains significantly improved mechanical strength, wear resistance, and electrical conductivity, all while retaining the exceptional chemical inertness and low-friction characteristics that make PTFE so valuable.

The central purpose of adding carbon to PTFE is to overcome its primary weaknesses—poor wear resistance and deformation under load—without compromising its key strengths. This creates a high-performance material ideal for dynamic, high-load, or static-sensitive environments where virgin PTFE would fail.

Why Add Fillers to PTFE?

Virgin PTFE is an outstanding material known for its near-universal chemical resistance and an extremely low coefficient of friction. However, it is mechanically soft.

Under pressure, pure PTFE can deform or "creep." In dynamic applications involving friction and movement, it wears down quickly. Fillers are added to create a composite that mitigates these weaknesses.

The Role of the Carbon Filler

Carbon, added in either powder or fiber form (typically up to 35% by weight), acts as a reinforcing agent within the PTFE matrix. It provides a structural backbone that dramatically improves the material's physical properties.

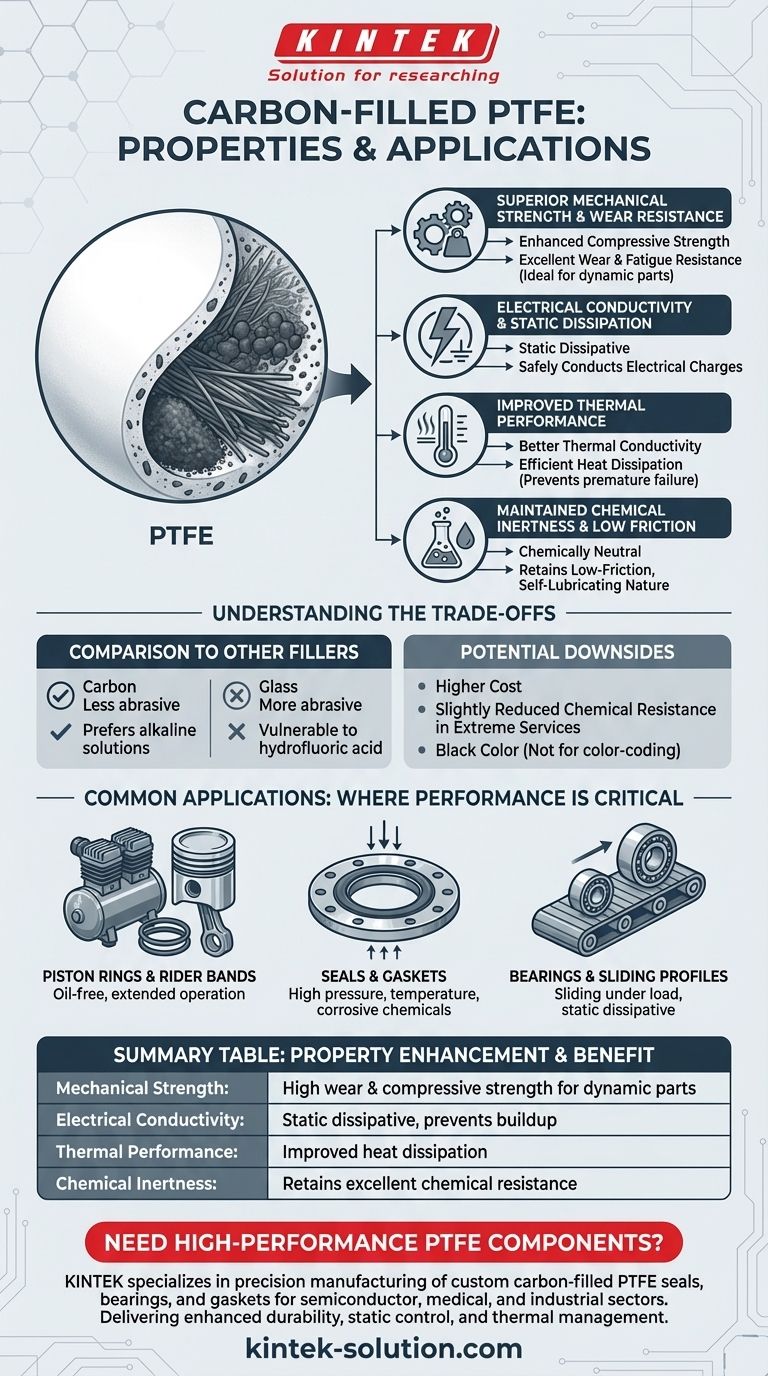

Key Property Enhancements of Carbon-Filled PTFE

The addition of carbon creates a synergy, resulting in a material far more capable than its base components alone.

Superior Mechanical Strength and Wear Resistance

This is the primary reason for choosing carbon-filled PTFE. It exhibits excellent wear and fatigue resistance, making it suitable for parts that move or are in constant contact with other surfaces.

The material also has much higher compressive strength than unfilled PTFE. This allows it to be used in applications with heavy static or dynamic loads with significantly less deformation.

Electrical Conductivity and Static Dissipation

Standard PTFE is an excellent electrical insulator. However, this can allow for the buildup of static electricity in dynamic applications, which can be a major problem in sensitive electronics or explosive environments.

Carbon is electrically conductive, which makes the resulting composite static dissipative. It safely conducts electrical charges away, preventing dangerous static buildup.

Improved Thermal Performance

The carbon filler enhances the material's thermal conductivity. This allows it to dissipate heat generated from friction more effectively than virgin PTFE.

This property is critical in high-speed sliding or bearing applications, where excess heat can lead to premature failure.

Maintained Chemical Inertness and Low Friction

Crucially, carbon-filled PTFE retains the hallmark properties of its base material. It remains chemically neutral and is suitable for use in aggressive chemical and steam environments.

While any filler can slightly increase the coefficient of friction, the impact of carbon is minimal, preserving the material's excellent low-friction, self-lubricating nature.

Understanding the Trade-offs

While carbon-filled PTFE is a superior material for many applications, it's essential to understand its context and limitations.

Comparison to Other Fillers

Glass is another common filler for PTFE. While glass-filled PTFE also offers excellent mechanical strength, carbon has key advantages.

Carbon is less abrasive than glass, causing less wear on mating surfaces like stainless steel shafts. It is also preferred in environments with hydrofluoric acid or strong alkaline solutions, which can attack glass fibers.

Potential Downsides

The primary trade-off is cost, as filled grades are more expensive than virgin PTFE. Furthermore, while chemical resistance is excellent, it may be slightly reduced compared to 100% pure PTFE in the most extreme chemical services. Finally, its black color makes it unsuitable for applications requiring specific color-coding or visual inspection of the material's purity.

Common Applications: Where Performance is Critical

The unique properties of carbon-filled PTFE make it the material of choice for specific industrial components.

Piston Rings and Rider Bands

In oil-free compressors, the combination of self-lubrication, high wear resistance, and compressive strength allows carbon-filled PTFE piston rings and rider bands to operate for extended periods without external lubrication.

Seals and Gaskets

For applications involving high pressure, extreme temperatures, and corrosive chemicals, carbon-filled PTFE provides a reliable, non-leaking seal that resists deformation.

Bearings and Sliding Profiles

In any application where parts slide against each other under load, this material excels. Its static dissipative nature is especially valuable for conveyor components or machinery where static sparks are a hazard.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary engineering goal.

- If your primary focus is wear resistance under high loads: Carbon-filled PTFE is an excellent choice for dynamic components like bearings and seals that must resist deformation and wear.

- If your primary focus is preventing static buildup: This material is the definitive solution for sliding applications where discharging static electricity is critical for safety or operational integrity.

- If your primary focus is chemical resistance in a dynamic system: Carbon-filled PTFE offers a superb balance, providing the chemical inertness of PTFE with the mechanical durability needed for moving parts in corrosive environments.

Ultimately, carbon-filled PTFE serves as a powerful problem-solving tool for engineers facing challenges that exceed the capabilities of standard polymers.

Summary Table:

| Property Enhancement | Key Benefit |

|---|---|

| Mechanical Strength | High wear resistance and compressive strength for dynamic, high-load parts. |

| Electrical Conductivity | Static dissipative, preventing dangerous static buildup. |

| Thermal Performance | Improved heat dissipation from friction. |

| Chemical Inertness | Retains excellent chemical resistance in aggressive environments. |

Need high-performance PTFE components that can withstand extreme conditions?

KINTEK specializes in the precision manufacturing of custom carbon-filled PTFE components—including seals, bearings, piston rings, and gaskets—for the semiconductor, medical, laboratory, and industrial sectors. We leverage the superior properties of carbon-filled PTFE to deliver parts with enhanced durability, static control, and thermal management, ensuring reliability in your most demanding applications.

From prototyping to high-volume production, we deliver the quality and performance your project requires. Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom Machined Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

People Also Ask

- How does Teflon contribute to the effectiveness of sunscreens? Enhancing Durability and Water Resistance

- Why is PTFE approved for medical implants? Leveraging Biocompatibility for Medical Devices

- What makes PTFE difficult to adhere to or weld? Unlocking the Secrets of Teflon® Bonding

- What is PTFE and its basic chemical structure? The Key to Its Legendary Performance

- What are the recommended PTFE formulations for the chemical processing industry and why? Optimize for Durability and Chemical Resistance

- What are the key properties of PTFE? The Ultimate Material for Extreme Industrial Applications

- What are some everyday applications of Teflon? Discover Its Versatility in Your Life and Industry

- Is Teflon biodegradable and what are its environmental impacts? Understanding the 'Forever Material'