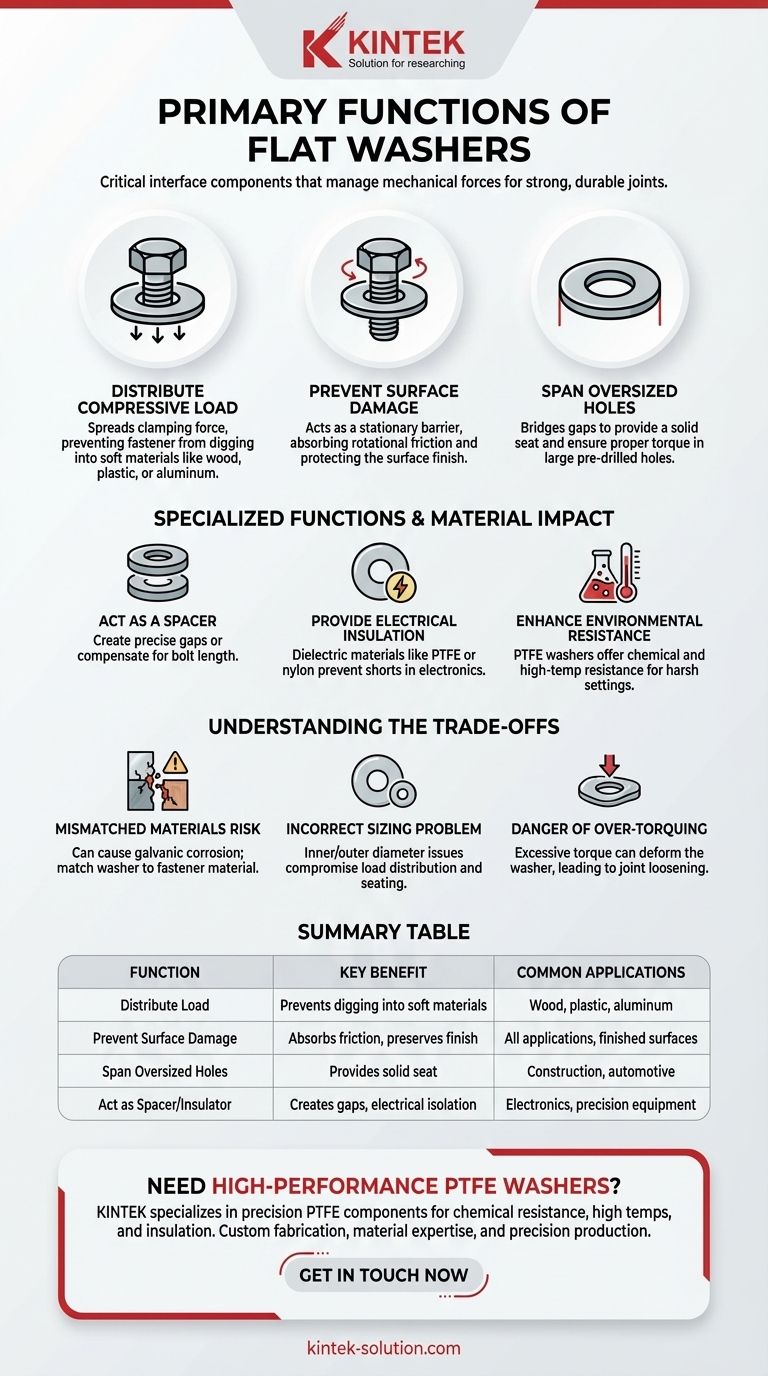

At its core, a flat washer serves three primary functions. It distributes the load of a threaded fastener, prevents the fastener from damaging the surface of the material it's being driven into, and can be used to span an oversized hole.

A flat washer is not just a piece of hardware; it is a critical interface component that manages mechanical forces. Understanding its function is essential for creating a joint that is not only strong but also durable and reliable over time.

The Core Mechanical Functions

The simple design of a flat washer belies its importance in a mechanical assembly. Its primary value comes from its ability to manage the intense pressure created by a tightened fastener.

Distributing Compressive Load

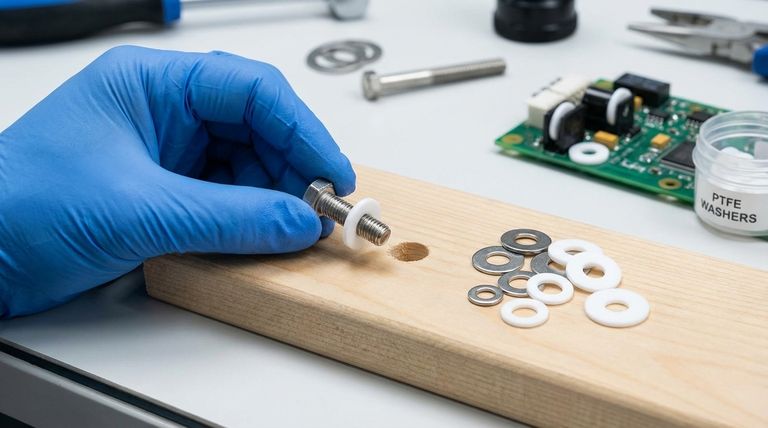

When you tighten a nut or bolt, all of that clamping force is concentrated in a small area directly under the head. A washer significantly increases this surface area.

This distributes the pressure, preventing the fastener head from digging into and damaging softer materials like wood, plastic, or aluminum. Think of it like a snowshoe, which spreads your weight to keep you from sinking into the snow.

Preventing Surface Damage

The act of tightening a fastener involves rotational friction. Without a washer, the turning motion of the bolt head or nut can scrape, gouge, and ruin the finish of the component's surface.

A flat washer acts as a stationary barrier between the rotating fastener and the workpiece, absorbing the rotational friction and preserving the surface integrity.

Spanning Oversized Holes

In some cases, a pre-drilled hole may be slightly larger than is ideal for the chosen fastener. A washer can effectively bridge this gap.

By covering the oversized hole, the washer provides a solid seat for the fastener head or nut, ensuring it can be properly torqued to create a secure joint.

Specialized Functions and Material Impact

Beyond the fundamental mechanical roles, washers are used for a variety of specialized tasks, which are often dictated by the material they are made from.

Acting as a Spacer

Washers have a standardized thickness and can be stacked to create a precise gap between two components. This is a common application when an assembly requires specific spacing or when a bolt is slightly too long for its intended hole.

Providing Electrical Insulation

In electronics and other applications, it's often necessary to electrically isolate a metal screw from the chassis or other components.

Washers made from dielectric materials like plastic, nylon, or PTFE are used to prevent the flow of electricity, avoiding short circuits.

Enhancing Environmental Resistance

The material of the washer is critical for performance in specific environments. While standard steel is common, specialized materials offer unique benefits.

PTFE washers, for example, provide excellent chemical and corrosion resistance, making them ideal for use in harsh industrial or high-temperature settings.

Understanding the Trade-offs

Using the wrong washer—or using the right washer incorrectly—can compromise the integrity of a joint. Awareness of the potential pitfalls is crucial.

The Risk of Mismatched Materials

Using a zinc-plated steel washer with stainless steel bolts can cause galvanic corrosion, where the less noble metal (zinc) corrodes prematurely. Always try to match the washer material to the fastener material.

The Problem of Incorrect Sizing

A washer whose inner diameter is too large for the bolt will not seat correctly and can shift under load. A washer with an outer diameter that is too small will fail to adequately distribute the load, defeating its primary purpose.

The Danger of Over-Torquing

Even with a washer, it is possible to apply too much torque. This can cause the washer itself to deform and warp, which will eventually lead to a loosening of the joint as the material settles.

Making the Right Choice for Your Goal

Selecting the correct washer is a simple step that ensures the long-term reliability of your project.

- If your primary focus is protecting a soft material like wood or plastic: Choose a standard steel washer with a wide outer diameter to maximize load distribution.

- If your primary focus is preventing corrosion or creating electrical insulation: Select a washer made from a material suited to the need, such as stainless steel, plastic, or PTFE.

- If your primary focus is spanning a large hole or creating a precise gap: Use a fender washer (for its large outer diameter) or a standard washer of known thickness.

Ultimately, this small, unassuming component plays a vital role in ensuring your assembly is secure, protected, and built to last.

Summary Table:

| Function | Key Benefit | Common Applications |

|---|---|---|

| Distribute Load | Prevents fastener from digging into soft materials | Wood, plastic, aluminum assemblies |

| Prevent Surface Damage | Absorbs rotational friction, preserves finish | All applications, especially finished surfaces |

| Span Oversized Holes | Provides a solid seat for fastener in large holes | Construction, automotive, machinery |

| Act as a Spacer/Insulator | Creates gaps or provides electrical isolation | Electronics, precision equipment, plumbing |

Need High-Performance PTFE Washers for Demanding Applications?

KINTEK specializes in manufacturing precision PTFE components, including flat washers, for industries where chemical resistance, high temperatures, and electrical insulation are critical. Our washers are ideal for semiconductor, medical, laboratory, and industrial applications.

We offer:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: Superior PTFE for harsh environments.

- Precision Production: Ensuring reliable performance and durability.

Contact us today to discuss your specific requirements and get a quote for washers that guarantee a secure, long-lasting joint.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How was Teflon discovered and when was it commercialized? The Accidental Invention of a Wonder Polymer

- What are the non-toxic properties of PTFE? Ensure Safety in Medical, Food, and Industrial Applications

- What chemicals is Teflon resistant to? The Ultimate Guide to PTFE Chemical Inertness

- What are the unique characteristics of porous ePTFE? Unlock Versatile Solutions for Complex Engineering Challenges

- Why is PTFE considered a versatile material? Unmatched Chemical & Thermal Properties

- What forms does expanded PTFE typically come in? Discover the Right ePTFE for Your Sealing & Filtration Needs

- How does PTFE perform under extreme temperatures in aerospace environments? Ensure Mission Success from -270°C to 260°C

- What is the difference between virgin and modified PTFE? Choose the Right Material for Your Application