In short, PTFE envelope gaskets are primarily used to seal flange connections in industries that handle aggressive chemicals, especially where delicate flange surfaces like glass or enamel are involved. Their unique composite design combines the unparalleled chemical resistance of PTFE with the mechanical strength of a core material, making them ideal for chemical processing, pharmaceutical, and food production applications.

A PTFE envelope gasket is a specialized solution for a difficult problem: how to create a chemically inert seal that doesn't suffer from the structural weakness of pure PTFE. It uses a robust inner core for strength and a thin outer PTFE layer for protection, providing the best of both worlds for demanding environments.

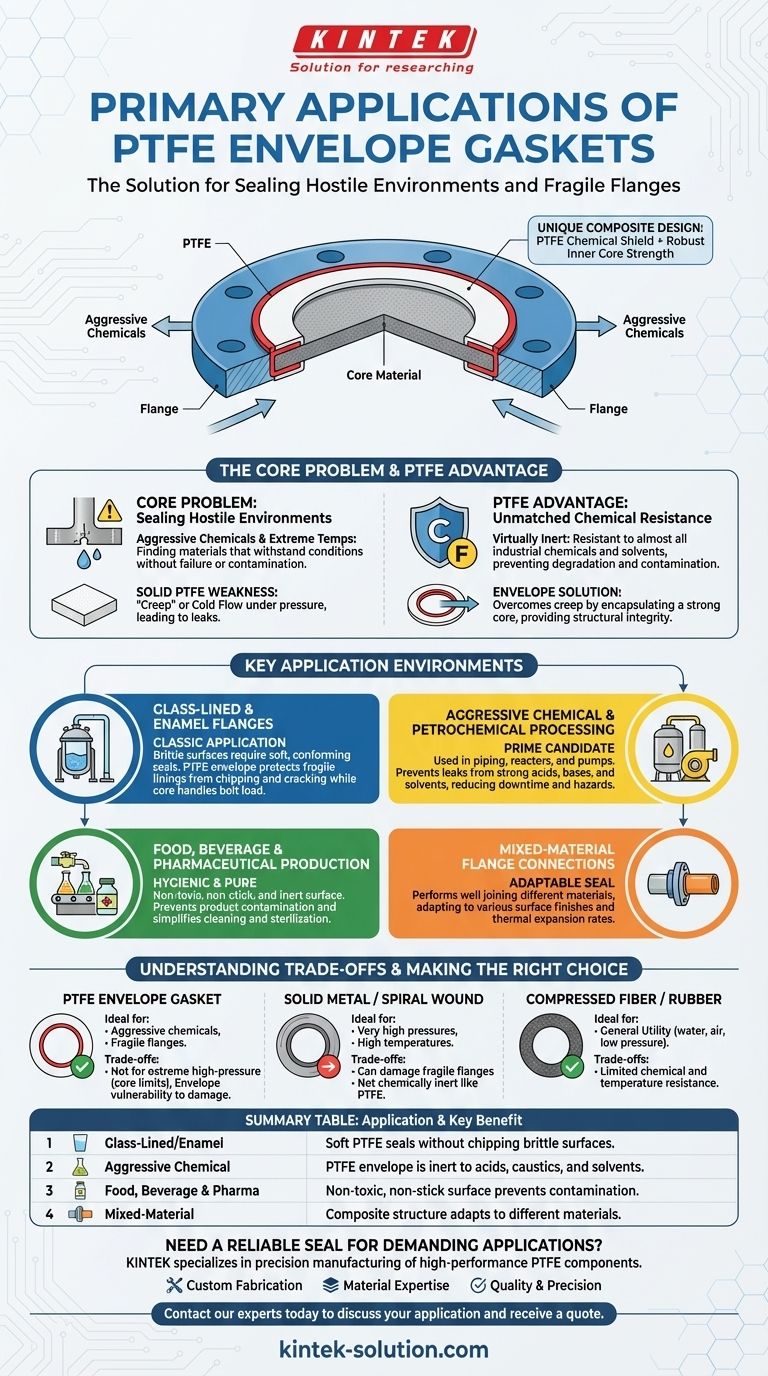

The Core Problem: Sealing Hostile Environments

Many industrial processes require sealing flanges that are exposed to highly corrosive chemicals, extreme temperatures, or both. Finding a single gasket material that can withstand these conditions without failing or contaminating the process media is a significant engineering challenge.

The PTFE Advantage: Unmatched Chemical Resistance

The primary reason for using a PTFE envelope is the material itself. Polytetrafluoroethylene (PTFE) is a fluoropolymer that is virtually inert to almost all industrial chemicals and solvents.

Its key benefit is that it will not degrade, swell, or leach when exposed to aggressive acids, caustics, or other reactive substances. This ensures the integrity of the seal and the purity of the process fluid.

The Envelope Solution: Overcoming PTFE's Weakness

While chemically superior, a gasket made from solid PTFE has a major drawback: creep, also known as cold flow. Under the pressure of a bolted flange, solid PTFE tends to slowly deform and "flow" out of the joint, causing a loss of bolt torque and an eventual leak.

The envelope gasket solves this by using a thin "envelope" or jacket of PTFE that encapsulates a more mechanically stable core material, such as compressed fiber, graphite, or rubber. This design provides the structural strength and creep resistance of the core, while the PTFE envelope provides the necessary chemical barrier.

Key Application Environments

The unique construction of PTFE envelope gaskets makes them the go-to solution in several specific and demanding applications.

Glass-Lined and Enamel Flanges

This is a classic application. Glass-lined steel reactors and pipes are common in the chemical and pharmaceutical industries. These flange surfaces are extremely brittle and can easily be damaged by hard gasket materials.

The soft, conforming nature of the PTFE envelope creates an effective seal without chipping or cracking the fragile glass lining. The core material provides the rigidity needed to handle bolt loads.

Aggressive Chemical and Petrochemical Processing

Any process involving strong acids, bases, solvents, or other corrosive media is a prime candidate for PTFE envelope gaskets. They are used extensively in piping systems, reactors, and pumps to prevent leaks that could be hazardous to personnel and the environment.

Their durability in these conditions reduces downtime and the frequency of gasket replacements.

Food, Beverage, and Pharmaceutical Production

In these industries, preventing product contamination is paramount. PTFE is non-toxic, non-stick, and does not impart any taste, color, or odor to the process media.

The non-stick surface also simplifies cleaning and sterilization procedures, preventing material buildup and ensuring hygienic conditions.

Mixed-Material Flange Connections

These gaskets perform well when joining flanges of different materials, such as connecting a plastic pipe to a steel flange. The composite structure allows it to adapt to different surface finishes and thermal expansion rates while maintaining a reliable seal.

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are a specialized component, and it's important to understand their limitations.

Not a High-Pressure Champion

While they offer good pressure resistance, they are not intended for extremely high-pressure services (e.g., thousands of PSI) where a solid metal gasket, like a spiral wound or ring-type joint (RTJ), would be required. The ultimate pressure and temperature rating is determined by the core material, not just the PTFE.

Vulnerability of the Envelope

The PTFE envelope is relatively thin. It can be damaged by careless handling, improper installation, or scratches on the flange face. Any breach of the envelope will expose the less-resistant core material to the chemical media, leading to rapid gasket failure.

Cost and Complexity

PTFE envelope gaskets are a composite product and are generally more expensive than simpler, single-material gaskets like compressed non-asbestos fiber (CNAF) or EPDM rubber. Their use is justified only when the chemical resistance of PTFE is truly necessary.

Making the Right Choice for Your System

Selecting a gasket requires matching the material properties to the specific demands of the service.

- If your primary focus is sealing aggressive chemicals on fragile flanges: A PTFE envelope gasket is the definitive choice, offering chemical inertness and a soft sealing surface.

- If your primary focus is sealing very high pressures or temperatures with non-corrosive media: A solid metallic or spiral wound gasket is likely a more robust and cost-effective solution.

- If your primary focus is general utility service (e.g., water, air, low-pressure steam): A less expensive compressed fiber or rubber gasket is typically sufficient and more economical.

Ultimately, choosing a PTFE envelope gasket is a deliberate engineering decision for when chemical compatibility is the most critical factor in ensuring a safe and reliable seal.

Summary Table:

| Application Environment | Key Benefit of PTFE Envelope Gasket |

|---|---|

| Glass-Lined / Enamel Flanges | Soft PTFE layer seals without chipping brittle surfaces. |

| Aggressive Chemical Processing | PTFE envelope is inert to acids, caustics, and solvents. |

| Food, Beverage & Pharmaceutical | Non-toxic, non-stick surface prevents contamination. |

| Mixed-Material Flange Connections | Composite structure adapts to different materials and thermal expansion. |

Need a Reliable Seal for Demanding Applications?

PTFE envelope gaskets are a critical component for ensuring safety and preventing leaks in hostile environments. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom envelope gaskets.

We serve the semiconductor, medical, laboratory, and industrial sectors by providing:

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Expertise: Ensuring the right PTFE and core material combination for your specific pressure, temperature, and chemical requirements.

- Quality & Precision: Consistent, reliable parts that perform under pressure.

Let us help you solve your toughest sealing challenges. Contact our experts today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation