In short, PTFE lip seals are specified for demanding, high-performance rotating equipment where conventional elastomer seals would quickly fail. Their primary applications include industrial air and screw compressors, high-speed automotive components like turbochargers, aerospace systems, and a wide variety of pumps used in the chemical, pharmaceutical, and food processing industries.

The decision to use a PTFE lip seal is almost always driven by a need for reliability under extreme conditions. They are the go-to solution when an application involves high rotational speeds, aggressive chemicals, wide temperature ranges, or high pressures that are far beyond the capabilities of traditional rubber seals.

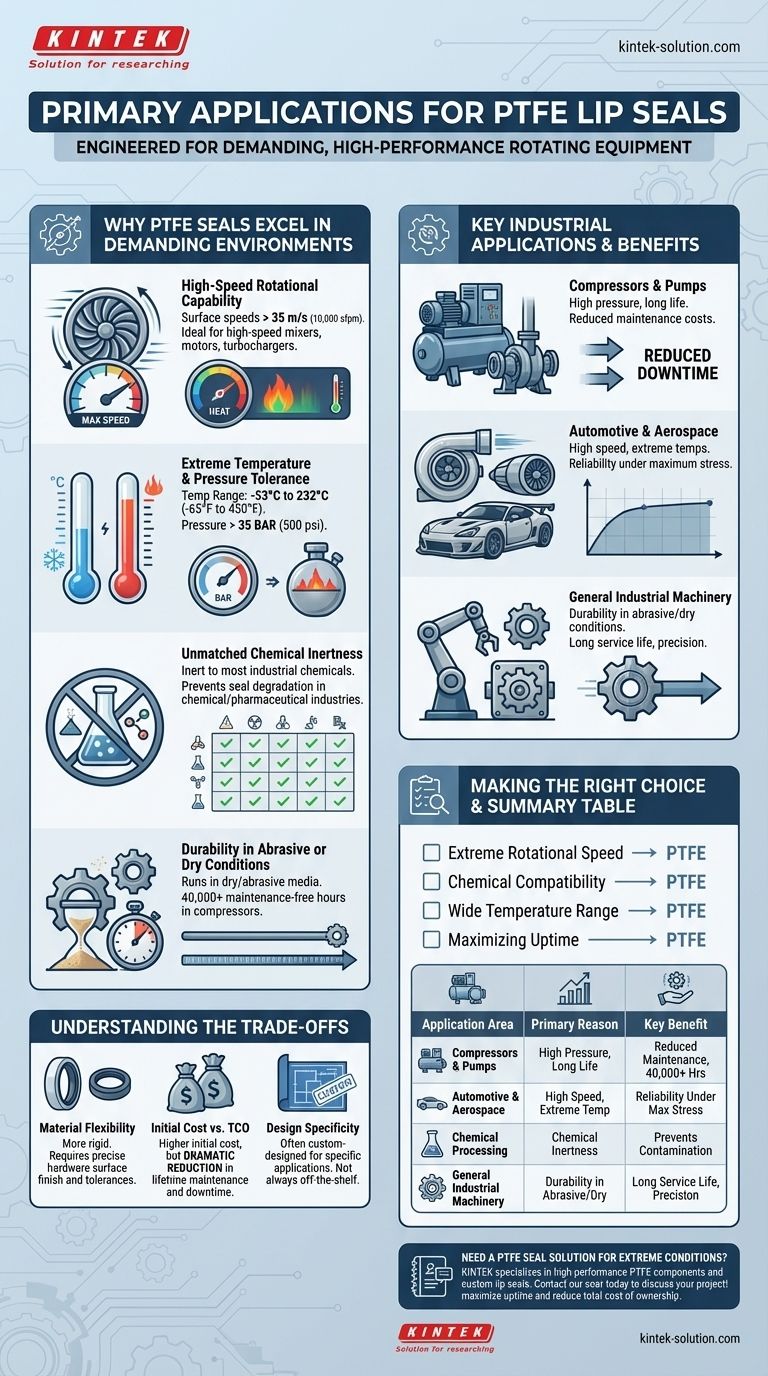

Why PTFE Seals Excel in Demanding Environments

The choice of a PTFE lip seal is a direct response to one or more specific operational challenges. Understanding their core material properties clarifies why they are essential in certain applications.

High-Speed Rotational Capability

PTFE's exceptionally low coefficient of friction allows these seals to handle surface speeds over 35 m/s (10,000 sfpm). This is critical for equipment like high-speed mixers, motors, spindles, and turbochargers where the heat generated by a standard elastomer seal would cause it to degrade and fail.

Extreme Temperature and Pressure Tolerance

These seals maintain their integrity across a vast temperature spectrum, typically from -53°C to 232°C (-65°F to 450°F). They also reliably seal pressures in excess of 35 BAR (500 psi). This makes them indispensable in aerospace systems, cryogenic equipment, and high-pressure hydraulic actuators.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This property makes it the default choice for sealing pumps, valves, and mixers in the chemical processing, pharmaceutical, and food and beverage industries, preventing seal degradation and process contamination.

Durability in Abrasive or Dry Conditions

Unlike elastomers that require lubrication to survive, PTFE seals can run in dry or abrasive media for extended periods. This unique capability leads to an exceptionally long service life, with some compressor applications achieving over 40,000 maintenance-free hours.

A Closer Look at Key Industrial Applications

While the principles are universal, seeing how they apply in specific sectors provides a clearer picture of their value.

Compressors and Pumps

In industrial equipment like screw compressors and fluid transfer pumps, reliability is paramount. PTFE seals provide a long-lasting, leak-free solution that significantly reduces maintenance frequency and operating costs, preventing costly unscheduled downtime.

Automotive and Aerospace

High-performance sectors rely on components that perform under maximum stress. PTFE seals are used in racing applications, turbochargers, aircraft engines, and brake systems where a combination of high speed, extreme temperatures, and absolute reliability is non-negotiable.

General Industrial Machinery

In robotics, gearboxes, motors, and blowers, PTFE seals offer a significant upgrade over standard components. Their longevity and resistance to wear ensure that critical machinery operates with greater precision and for longer intervals between servicing.

Understanding the Trade-offs

While highly capable, PTFE seals are an engineered solution, not a universal replacement for all seal types. Understanding their limitations is key to using them correctly.

Material Flexibility

PTFE is a much more rigid material than rubber. This means that the hardware's surface finish and dimensional tolerances are more critical for achieving a proper seal. It is less forgiving of imperfections than a highly compliant elastomer seal.

Initial Cost vs. Total Cost of Ownership

The initial procurement cost of a PTFE seal is typically higher than that of a standard elastomeric seal. However, this cost is often justified by the dramatic reduction in maintenance, downtime, and replacement frequency over the equipment's lifespan.

Design Specificity

Because of their material properties, PTFE seals are often custom-designed for a specific application. This ensures optimal performance but means they are less of an "off-the-shelf" commodity compared to standard elastomer sizes.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's strengths to your primary operational challenge.

- If your primary focus is extreme rotational speed: PTFE is the clear choice for applications like turbochargers, high-speed spindles, and racing gearboxes.

- If your primary focus is chemical compatibility: Use PTFE seals for pumps, mixers, and valves in chemical, pharmaceutical, or food processing.

- If your primary focus is a wide temperature range: Specify PTFE seals for aerospace, cryogenic systems, or high-temperature industrial processes.

- If your primary focus is maximizing uptime and longevity: PTFE seals are a strategic investment for critical equipment like industrial compressors where maintenance is difficult and costly.

Ultimately, choosing a PTFE lip seal is a decision to engineer for reliability where operating conditions are simply too demanding for conventional materials.

Summary Table:

| Application Area | Primary Reason for PTFE Use | Key Benefit |

|---|---|---|

| Compressors & Pumps | High pressure, long life | Reduced maintenance, 40,000+ hours |

| Automotive & Aerospace | High speed, extreme temperatures | Reliability under maximum stress |

| Chemical Processing | Chemical inertness | Prevents contamination, seal degradation |

| General Industrial Machinery | Durability in abrasive/dry conditions | Long service life, precision operation |

Need a PTFE seal solution for extreme conditions? KINTEK specializes in manufacturing high-performance PTFE components, including custom lip seals, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a reliable seal designed for your specific application's demands, maximizing uptime and reducing total cost of ownership. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What advantages do Teflon sheets offer for sublimation printing? Achieve Flawless, Professional Transfers

- What are the key properties of PTFE that benefit bellows and diaphragms? Achieve Unmatched Reliability in Harsh Environments

- In which industries are expanded PTFE gaskets commonly used? Essential Sealing Solutions for Demanding Sectors

- How are PTFE rubber seals constructed? Precision Engineering for High-Performance Sealing

- What are O-rings and why are they commonly used? A Guide to Simple, Reliable Sealing

- What factors should be considered when selecting an expanded PTFE gasket? Optimize Your Seal for Performance

- What are the standard bearing assembly configurations for PTFE slide bearings? Choose the Right PTFE Bearing for Your Project

- What are PTFE bellows and what are they made of? Solve Tough Chemical & Thermal Challenges