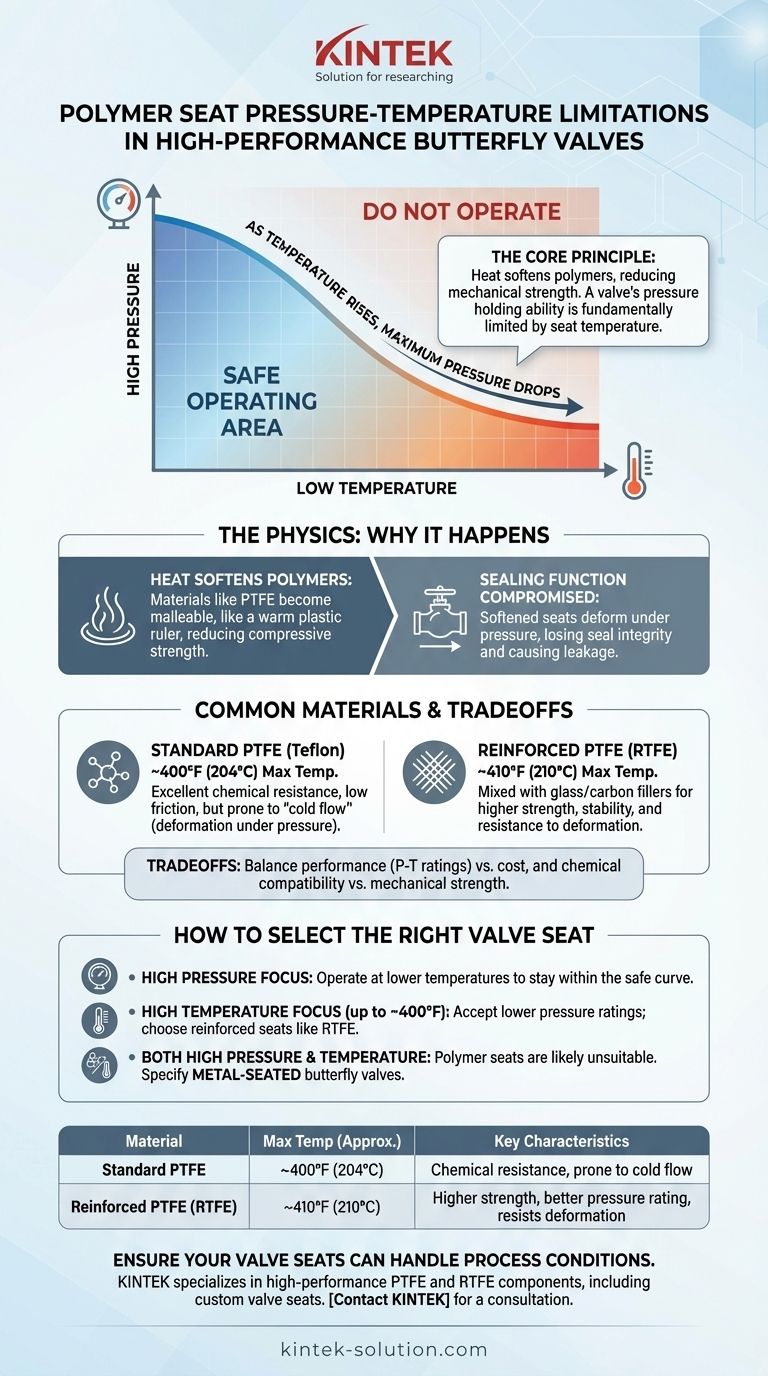

As a general rule, the pressure rating of a polymer seat in a high-performance butterfly valve has an inverse relationship with its operating temperature. For example, a common glass-reinforced PTFE seat that can handle moderate pressure at ambient temperatures may only be rated for around 200 psi (13.8 bar) at its upper temperature limit of 410°F (210°C). As the temperature rises, the maximum allowable pressure drops significantly.

The core principle you must understand is that heat softens polymers, reducing their mechanical strength. This means a valve's ability to hold pressure is fundamentally limited by the temperature of the seat material, a relationship defined by the manufacturer's pressure-temperature chart.

The Physics Behind the Limitation

The pressure and temperature limits aren't arbitrary; they are dictated by the physical properties of the polymer seat material. Understanding this relationship is key to selecting a reliable valve.

How Temperature Affects Polymer Strength

Polymers, including the PTFE (Teflon) variants used in valve seats, become softer and more malleable as they get hotter. Think of a plastic ruler on a cold day versus a hot day—it's much easier to bend when warm.

This softening effect directly reduces the material's compressive strength and its ability to resist deformation under load.

The Seat's Critical Sealing Function

The polymer seat's job is to create a positive, bubble-tight seal against the valve disc. It relies on its inherent strength and elasticity to press firmly against the disc edge.

When the seat softens from heat, the force from the system pressure can cause it to deform or extrude out of its retaining groove. This leads to a loss of sealing integrity and valve leakage.

Using the Pressure-Temperature (P-T) Chart

Every high-performance butterfly valve manufacturer provides a pressure-temperature (P-T) chart for each seat material. This chart is your definitive guide.

The chart typically shows temperature on the x-axis and pressure on the y-axis. A curve runs from the top-left (high pressure, low temp) to the bottom-right (low pressure, high temp), defining the safe operating area. Never operate the valve outside this curve.

Common Polymer Seat Materials

While many advanced polymers exist, a few dominate the market for high-performance butterfly valves.

Standard PTFE (Teflon)

PTFE is known for its exceptional chemical resistance and low-friction surface. However, it is mechanically weak and prone to a phenomenon called "cold flow," where the material slowly deforms under pressure, even at room temperature.

Reinforced PTFE (RTFE)

This is the most common material for soft-seated, high-performance valves. Standard PTFE is mixed with filler materials, typically glass fibers or carbon, to create RTFE.

These fillers act like rebar in concrete, dramatically increasing the material's strength, stability, and resistance to cold flow. This allows RTFE seats to handle significantly higher pressures and temperatures than standard PTFE.

Understanding the Trade-offs

Selecting a seat material is not just about finding the highest temperature rating. It involves balancing competing factors.

Performance vs. Cost

Engineered polymers and more robust reinforcement materials (like carbon-filled PTFE) offer superior P-T ratings but come at a higher cost. For less demanding services, a standard RTFE is often the most economical choice.

Chemical Compatibility vs. Mechanical Strength

You must ensure the seat material is fully compatible with your process media. A material with an excellent P-T rating is useless if it will be chemically attacked and degraded by the fluid or gas it is controlling.

The Risk of Exceeding Limits

Operating a valve outside its published P-T curve is a significant safety risk. The seat can fail catastrophically, resulting in a sudden loss of containment. This can lead to process downtime, environmental incidents, and personnel hazards.

How to Select the Right Valve Seat

Always consult the specific valve manufacturer's P-T chart. However, you can use these general principles to guide your decision-making.

- If your primary focus is high pressure: You will be limited to operating at lower temperatures to stay within the seat's safe operating area.

- If your primary focus is high temperature (up to ~400°F): You must accept a significantly lower maximum operating pressure and should specify a seat material like glass-reinforced RTFE.

- If your application requires both high pressure and high temperature: A polymer-seated valve is likely the wrong technology, and you should specify a metal-seated butterfly valve instead.

Your final selection must be based on a careful review of the manufacturer's engineering data for your specific service conditions.

Summary Table:

| Material | Max Temp (Approx.) | Key Characteristics |

|---|---|---|

| Standard PTFE | ~400°F (204°C) | Excellent chemical resistance, prone to cold flow |

| Reinforced PTFE (RTFE) | ~410°F (210°C) | Higher strength, better pressure rating, resists deformation |

Ensure your valve seats can handle the pressure and temperature of your process.

KINTEK specializes in manufacturing high-performance PTFE and RTFE components, including custom valve seats for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication capabilities, from prototypes to high-volume orders, ensure you get a component that meets your exact pressure-temperature requirements.

Contact KINTEK today for a consultation on your specific application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability