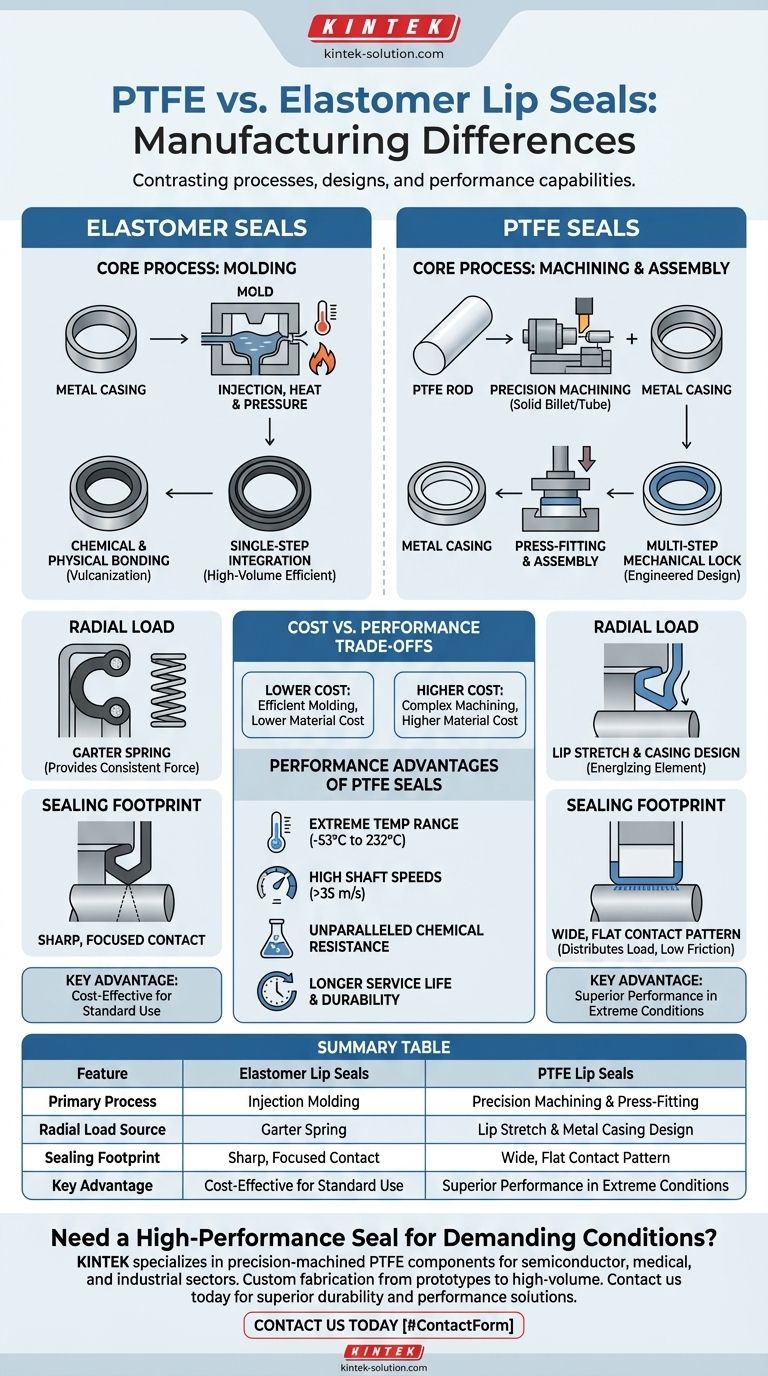

The primary manufacturing difference between PTFE and elastomer lip seals lies in how the sealing element is joined to the metal case. Elastomer seals are created by molding the rubber-like material directly onto the casing in a single, integrated process. In contrast, PTFE seals require a multi-step process where the lip is first machined from a solid billet of PTFE and then mechanically press-fitted into the casing.

The choice between these seals is dictated by their manufacturing reality. Elastomer molding offers a cost-effective solution for standard applications, while PTFE's more complex machining and assembly process enables a seal design that excels in high-stress environments where elastomers cannot survive.

The Core Process Distinction: Molding vs. Machining

The fundamental production method for each seal type is the most significant point of divergence, directly influencing their final cost and design characteristics.

Elastomer Seals: The Molding Process

Elastomer seals are produced by placing a metal casing into a mold and then injecting the elastomeric compound. Heat and pressure vulcanize the material, causing it to cure and bond chemically and physically to the casing.

This single-step process is highly efficient and well-suited for high-volume production, making elastomer seals a cost-effective choice for a wide range of common applications.

PTFE Seals: The Machining and Assembly Process

PTFE is a semi-rigid thermoplastic that cannot be injection molded like an elastomer. Its production is therefore a two-stage process.

First, the seal lip is precision-machined from a solid tube or rod of PTFE material. Second, this finished lip is carefully press-fitted into a pre-formed metal casing, relying on precise dimensions to create a secure mechanical lock.

How Manufacturing Drives Design and Function

These distinct manufacturing paths lead to fundamentally different seal designs, each optimized for the properties of its core material.

The Impact on Radial Load

Elastomer seals are flexible and typically rely on a garter spring embedded within the lip to provide a consistent radial force against the shaft.

PTFE seals, being more rigid, do not use springs. They generate their sealing force from the controlled lip stretch during installation and the engineered bend radius of the metal casing, which acts as the energizing element.

The Difference in Sealing Footprint

The design of the sealing lip itself is a direct result of the material properties. Elastomer seals typically have a relatively sharp, focused contact point with the shaft.

PTFE seals are designed with a wider, flatter lip contact pattern. This design distributes the load over a larger area, resulting in lighter unit loading. This is critical for minimizing wear and heat generation, leveraging PTFE's inherently low friction to enable high-speed operation.

Understanding the Trade-offs: Cost vs. Performance

The manufacturing method is the primary driver behind the cost and performance differences between the two seal types.

Cost Implications

PTFE seals are significantly more expensive than their elastomeric counterparts. This is due to a combination of two factors.

First, the raw PTFE material is more costly than standard elastomer compounds. Second, the multi-step process of machining and assembly is more labor-intensive and slower than the high-volume molding process.

Performance Advantages of PTFE

The higher cost of PTFE seals is justified by their superior performance in demanding conditions where elastomers would quickly fail.

PTFE offers an exceptional temperature range (from -53°C to 232°C), can handle extremely high shaft speeds (over 35 m/s), and provides unparalleled chemical resistance against aggressive media, solvents, and acids. Its durability and low-friction nature ensure a longer service life in high-stress applications.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its manufacturing-derived capabilities to your specific operational needs.

- If your primary focus is cost-effectiveness for a standard application: Elastomer seals are the ideal choice due to their efficient molding process and lower material cost.

- If your primary focus is performance under extreme conditions: PTFE seals are necessary for their ability to withstand high speeds, aggressive chemicals, and wide temperature ranges.

- If your primary focus is longevity in a high-stress environment: The superior wear resistance and durability of machined PTFE seals provide a longer, more reliable service life.

Ultimately, the manufacturing method is a direct reflection of the material's capabilities, guiding you to the right seal for your specific operational demands.

Summary Table:

| Feature | Elastomer Lip Seals | PTFE Lip Seals |

|---|---|---|

| Primary Process | Injection Molding | Precision Machining & Press-Fitting |

| Radial Load Source | Garter Spring | Lip Stretch & Metal Casing Design |

| Sealing Footprint | Sharp, Focused Contact | Wide, Flat Contact Pattern |

| Key Advantage | Cost-Effective for Standard Use | Superior Performance in Extreme Conditions |

Need a High-Performance Seal for Demanding Conditions?

Your application's demands—whether extreme temperatures, high speeds, or aggressive chemicals—directly determine the right seal manufacturing process. At KINTEK, we specialize in precision-machined PTFE components (including seals, liners, and labware) for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a seal engineered for superior durability and performance.

Contact us today to discuss your specific requirements and let our expertise provide a solution that lasts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance