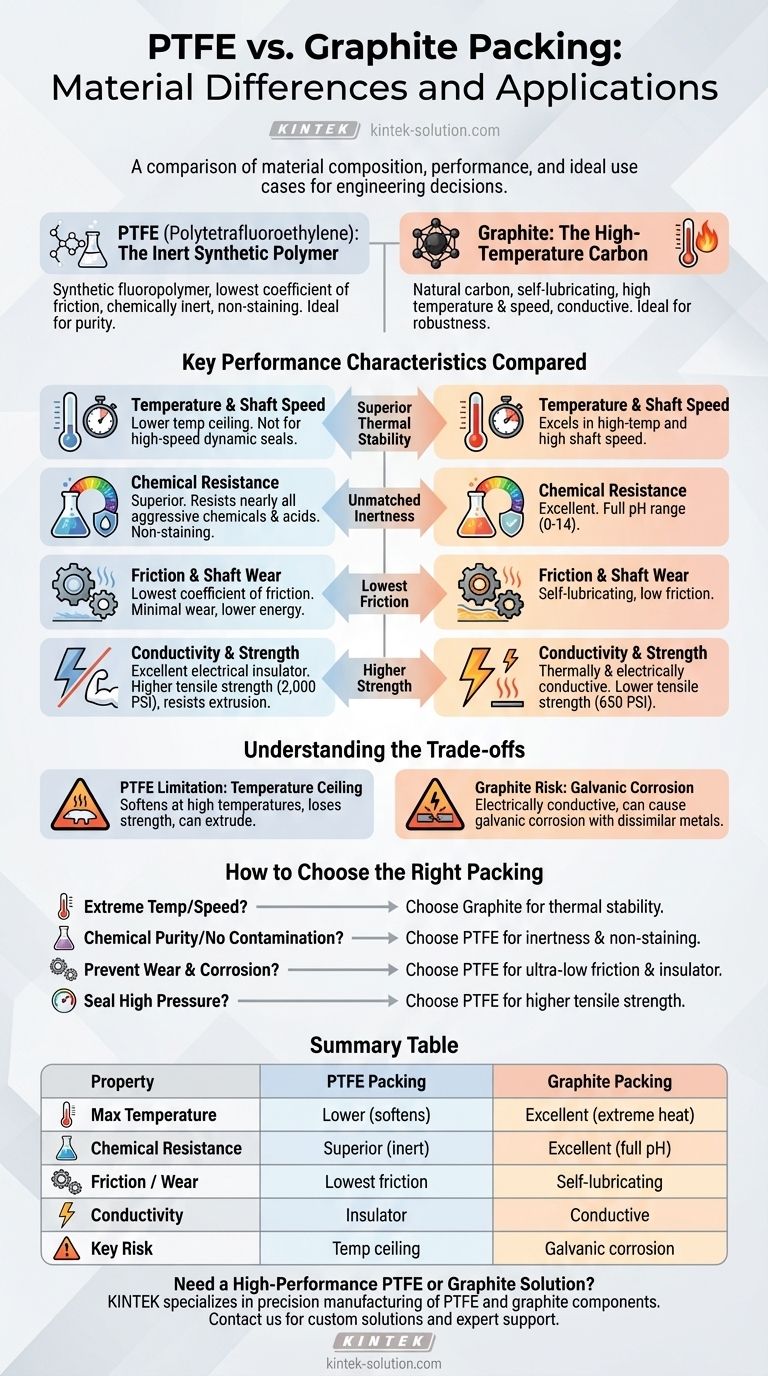

At their core, PTFE and graphite packing differ fundamentally in their material composition, which dictates their ideal use cases. Graphite is a natural, carbon-based material ideal for high-temperature and high-speed applications, while PTFE is a synthetic polymer prized for its exceptional chemical resistance and extremely low friction. The choice between them is a critical engineering decision based on these distinct properties.

Choosing the right packing isn't about which material is "better," but which is precisely suited for your specific operating conditions. PTFE is the chemically pure, low-friction specialist, whereas graphite is the robust, high-temperature workhorse.

Material Origins and Core Nature

The performance differences between these two materials begin with their fundamental composition. Understanding this is key to selecting the right one.

Graphite: The High-Temperature Carbon

Graphite packing is braided from a natural, inorganic form of pure carbon. This composition makes it inherently self-lubricating and capable of withstanding extreme temperatures and high shaft speeds far beyond the limits of synthetic materials. It typically appears as a black, braided rope.

PTFE: The Inert Synthetic Polymer

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer, the same family of materials used for non-stick coatings. This gives it the lowest coefficient of friction of almost any solid and makes it nearly universally inert. PTFE packing is white and is often preferred where product purity is critical.

Key Performance Characteristics Compared

Your application's specific demands—temperature, chemicals, and equipment sensitivity—will determine which packing is the correct choice.

Temperature and Shaft Speed

This is one of the most significant differentiators. Graphite excels in high-temperature services and at high shaft speeds where other materials would degrade. PTFE has a much lower temperature ceiling and is not typically used for high-speed dynamic seals without specialized construction or lubrication.

Chemical Resistance

Both materials offer outstanding chemical resistance across a full pH range of 0-14. However, PTFE is superior, resisting nearly all aggressive chemicals, acids, and corrosive gases. Its only notable exception is molten alkali metals. Because it is a pure polymer, PTFE is also non-staining, a critical factor for food, beverage, and pharmaceutical applications.

Friction and Shaft Wear

PTFE has the lowest coefficient of friction, which means it generates less heat and causes minimal wear on pump shafts and valve stems. While graphite is also self-lubricating and has low friction, PTFE's exceptionally slick surface is unmatched and directly contributes to longer equipment life and lower energy consumption.

Conductivity and Mechanical Strength

Graphite is highly conductive, both thermally and electrically. Its ability to dissipate heat is an advantage in high-speed applications, but its electrical conductivity can be a major drawback. PTFE, by contrast, is an excellent electrical insulator. In terms of strength, PTFE is significantly more robust, with a tensile strength of 2,000 PSI compared to graphite's 650 PSI, making it more resistant to extrusion under high pressure.

Understanding the Trade-offs

Selecting a material is always an exercise in balancing strengths and weaknesses. Being aware of the potential downsides is critical for reliable operation.

The Risk of Graphite: Galvanic Corrosion

Because graphite is electrically conductive, it can create a galvanic cell when used with dissimilar metals in the presence of an electrolyte (like water). This can lead to galvanic corrosion, severely damaging valve stems or pump shafts. This risk makes graphite unsuitable for many applications involving stainless steel or other noble metals unless a corrosion inhibitor is used.

The Limitation of PTFE: Temperature Ceiling

The primary weakness of standard PTFE packing is its relatively low temperature limit. As temperatures rise, PTFE can soften, lose its mechanical strength, and extrude from the stuffing box, leading to seal failure. This makes it inappropriate for high-temperature steam, hot oil, or other demanding thermal applications where graphite thrives.

How to Choose the Right Packing for Your Application

Base your decision on the most demanding aspect of your operational environment.

- If your primary focus is extreme temperature or high shaft speed: Choose graphite for its superior thermal stability and heat dissipation.

- If your primary focus is chemical purity and avoiding contamination: Choose PTFE for its inertness and non-staining properties.

- If your primary focus is preventing equipment wear and galvanic corrosion: Choose PTFE for its ultra-low friction and non-conductive nature.

- If your primary focus is sealing high pressures in moderate temperatures: Choose PTFE for its higher tensile strength and resistance to extrusion.

Making an informed choice between these materials ensures you are engineering for reliability, safety, and long-term performance.

Summary Table:

| Property | PTFE Packing | Graphite Packing |

|---|---|---|

| Max Temperature | Lower (softens at high temp) | Excellent (extreme heat) |

| Chemical Resistance | Superior (inert, non-staining) | Excellent (full pH range) |

| Friction / Wear | Lowest coefficient of friction | Self-lubricating, good |

| Conductivity | Excellent electrical insulator | Thermally & electrically conductive |

| Key Risk | Temperature ceiling | Galvanic corrosion |

Need a High-Performance PTFE or Graphite Solution?

Choosing the right packing material is critical for the reliability and safety of your equipment. KINTEK specializes in the precision manufacturing of PTFE and graphite components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We help you navigate material selection and deliver custom-fabricated parts, from prototypes to high-volume orders, ensuring optimal performance for your specific operating conditions.

Contact KINTEK today to discuss your application requirements and receive expert support.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the characteristics of PTFE coatings? Unlock Extreme Performance for Your Components

- What maintenance practices extend the lifespan of PTFE expansion bellows? A Guide to Maximizing Uptime

- What are the key considerations for successful PTFE machining? Master Precision for Soft Materials

- How does the chemical resistance of PTFE gaskets benefit industrial applications? Achieve Unmatched Reliability

- Why are PTFE gaskets popular in various industries? Unmatched Chemical Resistance & Reliability

- Why is PTFE a preferred material for medical device seals? Ensuring Safety, Reliability, and Performance

- What is the difference between a ball valve seat and an O-ring? Master Valve Sealing for Reliable Performance

- In which industries or applications are PTFE O-rings typically used? Solve Extreme Sealing Challenges