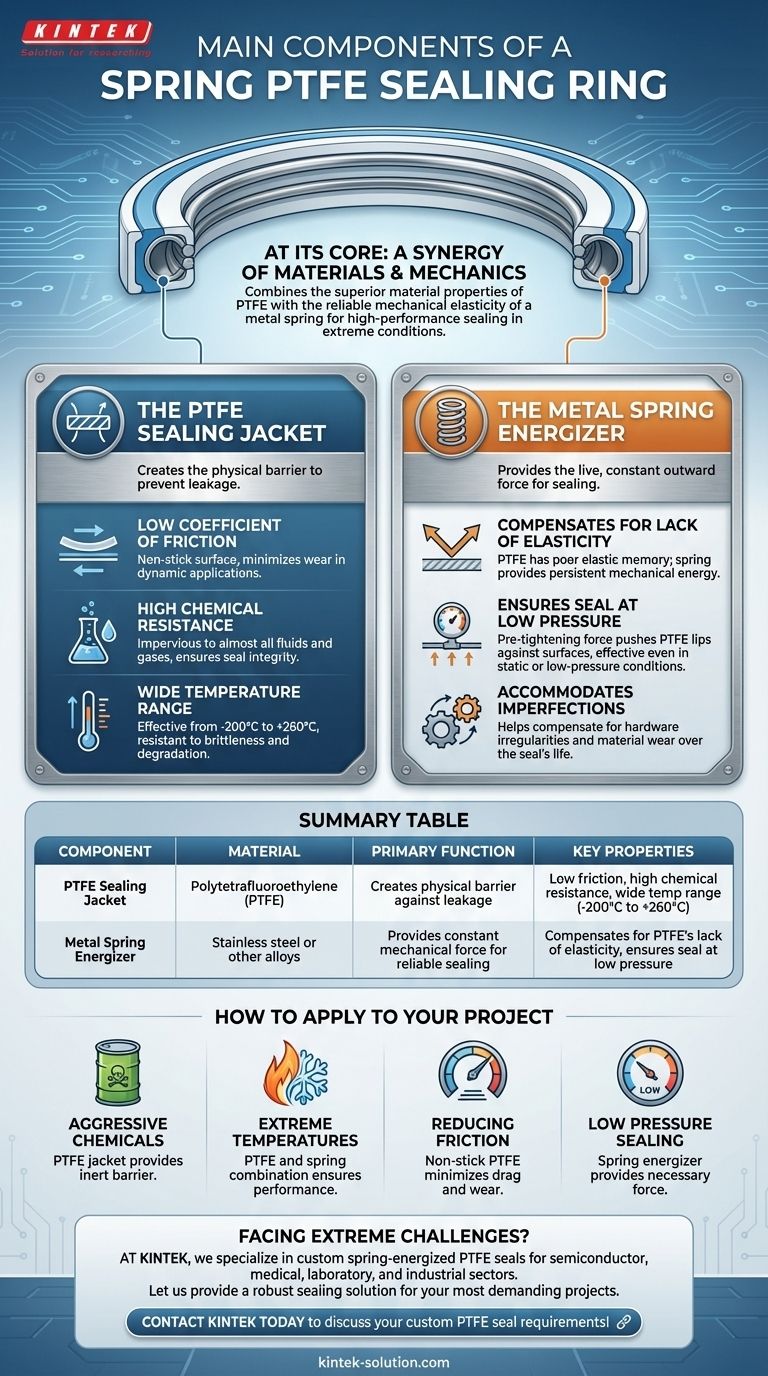

At its core, a spring-energized PTFE seal consists of two primary components. These are a precision-machined sealing jacket, almost always made from Polytetrafluoroethylene (PTFE), and a metal spring energizer nestled inside it. The PTFE jacket provides the low-friction, chemically inert sealing surface, while the internal spring supplies the constant mechanical force needed to maintain a reliable seal.

The fundamental design principle is to combine the superior material properties of PTFE with the reliable mechanical elasticity of a metal spring. This creates a high-performance seal that functions in conditions where traditional elastomeric seals would quickly fail.

Deconstructing the Two Core Components

To understand the effectiveness of this seal, we must look at the specific role each of its two parts plays in the system.

The PTFE Sealing Jacket

The jacket is the body of the seal that makes direct contact with the hardware. It is responsible for creating the physical barrier that prevents leakage.

PTFE is the material of choice for this component due to its unique combination of properties. It possesses an extremely low coefficient of friction, creating a non-stick surface that minimizes wear in dynamic applications.

Furthermore, its high chemical resistance makes it virtually impervious to all fluids and gases. This inertness ensures the seal's integrity when exposed to aggressive media.

Finally, PTFE operates effectively across an exceptionally wide temperature range, typically from -200°C to +260°C, environments that would cause standard rubber seals to become brittle or degrade.

The Metal Spring Energizer

The spring is the engine of the seal, providing the live, constant outward force needed for effective sealing.

Unlike rubber, PTFE is not an elastomer; it has poor "elastic memory" and will not rebound to its original shape after being compressed. The spring compensates for this by providing persistent mechanical energy.

This pre-tightening force pushes the lips of the PTFE jacket against the sealing surfaces, ensuring a tight seal is maintained even at very low pressures or in static conditions. It also helps accommodate minor imperfections in the hardware and compensates for material wear over the seal's life.

Understanding the Trade-offs

While highly effective, this composite design has specific characteristics that must be considered. Understanding these is crucial for proper application.

The Necessity of the Spring

The reliance on a spring is a direct result of PTFE's primary limitation: its lack of elasticity. Without the energizer, a pure PTFE ring would fail to seal effectively after initial compression or during pressure fluctuations. The seal's performance is entirely dependent on the synergy between both components.

Chemical and Thermal Limitations

While the PTFE jacket is nearly universally compatible, there are rare exceptions. The references note that molten alkaline metals and specific halogenated compounds can degrade the material.

More importantly, the metal spring energizer itself must be chosen carefully to match the chemical and thermal environment of the application. An incompatible spring material would become a point of failure for the entire seal assembly.

Physical Strength and Wear

Standard PTFE, while excellent in many ways, can be susceptible to wear and extrusion under very high pressures. The selection of the right PTFE compound—sometimes with fillers like bronze or glass—and the correct spring force is critical to ensure physical strength and long-term durability.

How to Apply This to Your Project

The two-component design allows for targeted performance based on the primary challenge of your application.

- If your primary focus is aggressive chemical exposure: The PTFE jacket is the critical component, providing a nearly inert barrier to protect the system.

- If your primary focus is extreme temperature stability: The combination of PTFE's wide operating range and a properly selected metal spring ensures performance where elastomers cannot.

- If your primary focus is reducing friction in dynamic sealing: The non-stick properties of the PTFE jacket minimize drag, heat buildup, and wear on moving parts.

- If your primary focus is reliable sealing at low pressures: The spring energizer is the key, providing the consistent mechanical force needed when system pressure is not enough to actuate the seal.

By leveraging the distinct strengths of both the PTFE jacket and the metal spring, this seal design provides a robust solution for the most demanding engineering challenges.

Summary Table:

| Component | Material | Primary Function | Key Properties |

|---|---|---|---|

| PTFE Sealing Jacket | Polytetrafluoroethylene (PTFE) | Creates the physical barrier against leakage | Low friction, high chemical resistance, wide temperature range (-200°C to +260°C) |

| Metal Spring Energizer | Stainless steel or other alloys | Provides constant mechanical force for reliable sealing | Compensates for PTFE's lack of elasticity, ensures seal at low pressure |

Facing extreme temperatures, aggressive chemicals, or low-pressure sealing challenges?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom spring-energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals are engineered with the right PTFE compound and spring force for maximum durability and performance in your specific application.

Let us provide a robust sealing solution for your most demanding projects—from prototypes to high-volume production.

Contact KINTEK today to discuss your custom PTFE seal requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability