The core challenges in machining Teflon (PTFE) stem directly from the properties that make it so useful: its extreme softness, low-friction surface, and sensitivity to heat. These characteristics cause the material to deform under pressure, expand significantly when heated, and slide away from cutting tools rather than shearing cleanly. This makes achieving precise dimensions and a smooth finish exceptionally difficult without specialized techniques.

While PTFE's unique properties like chemical inertness and low friction are highly desirable, they are also the direct source of its machining challenges. Success depends less on power and more on finesse, focusing on managing heat buildup and physical deformation with sharp tools and controlled processes.

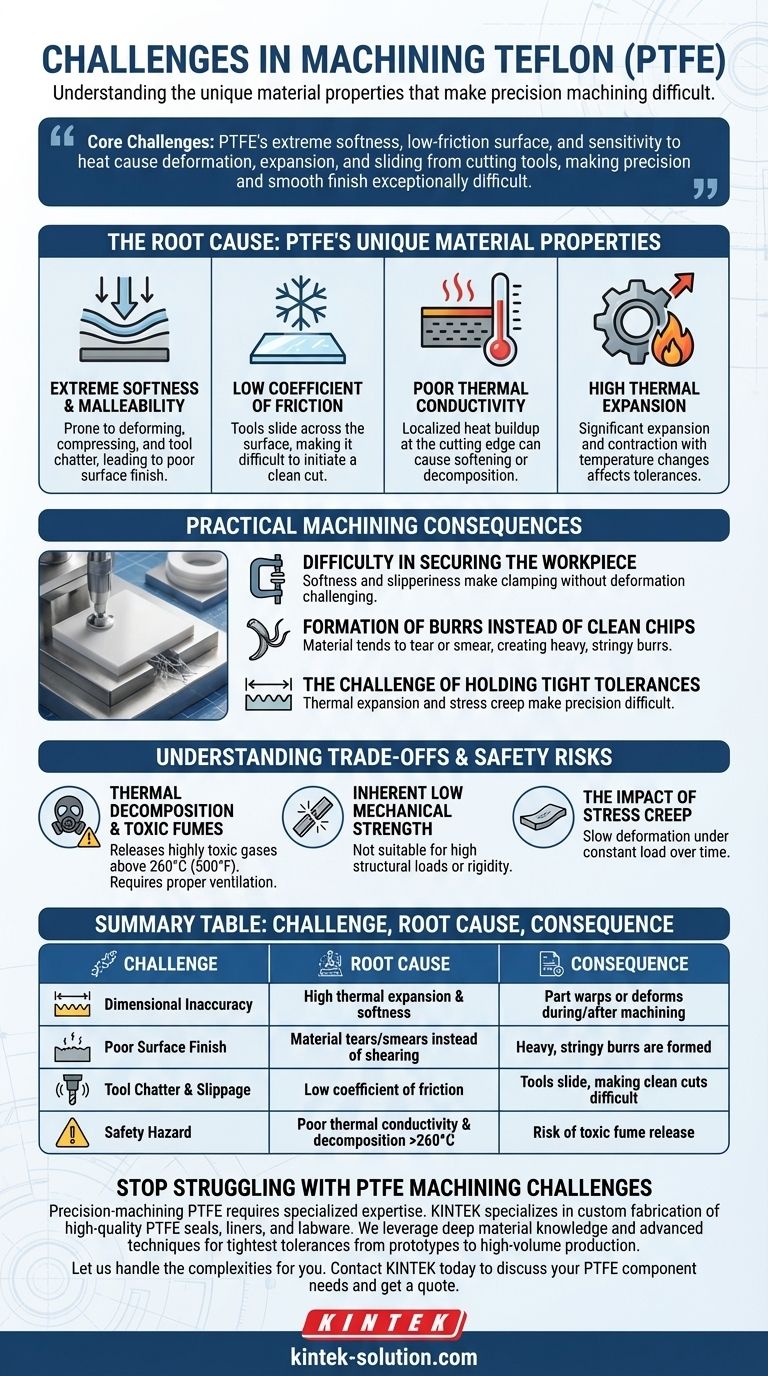

The Root Cause: PTFE's Unique Material Properties

To understand why machining PTFE is so difficult, we must first look at its fundamental characteristics. The material behaves unlike metals or even other common plastics.

Extreme Softness and Malleability

PTFE is an exceptionally soft material. When a cutting tool applies pressure, the material is prone to deforming or compressing rather than being cut cleanly.

This softness also leads to tool chatter, where the tool can vibrate against the workpiece, resulting in a poor surface finish.

A Low Coefficient of Friction

The famous non-stick quality of Teflon comes from its extremely low coefficient of friction. While excellent for its final application, this causes cutting tools to slide across the surface instead of biting in to create a chip.

This "slipperiness" makes it difficult to initiate a clean cut and can cause the material to push away from the tool, compromising accuracy.

Poor Thermal Conductivity

PTFE does not dissipate heat well. The friction from the machining process creates localized heat buildup right at the cutting edge, as the heat has nowhere to go.

This concentrated heat can quickly exceed PTFE's stable temperature range, causing it to soften, warp, or even decompose.

High Thermal Expansion

The material has a high coefficient of thermal expansion, meaning it expands and contracts significantly with changes in temperature.

Even a small amount of heat generated during cutting can cause the part to grow, making it impossible to hold tight tolerances. The dimension you measure when the part is warm will not be the same when it cools.

The Practical Machining Consequences

These material properties translate into predictable, tangible problems on the shop floor that every machinist must overcome.

Difficulty in Securing the Workpiece

Because PTFE is both soft and slippery, clamping it securely without deforming it is a major challenge. Overtightening a vise or fixture will crush the material and ruin the part's final dimensions.

Formation of Burrs Instead of Clean Chips

Instead of forming clean, brittle chips that break away, the soft nature of PTFE means it often tears or smears. This results in heavy, stringy burrs along the cut edges that are difficult to remove without damaging the part.

The Challenge of Holding Tight Tolerances

Between thermal expansion during the cut and the material's tendency to deform under pressure, achieving high precision is a constant battle. The material is also subject to stress creep, meaning it can slowly change shape over time if under residual stress from machining.

Understanding the Trade-offs and Safety Risks

Beyond the immediate machining difficulties, it is critical to understand the material's inherent limitations and safety hazards.

Thermal Decomposition and Toxic Fumes

This is the most critical safety consideration. When heated above 260°C (500°F), PTFE begins to decompose and can release highly toxic fluorocarbon gases.

Proper temperature control, effective cooling, and excellent ventilation are not just for part quality—they are essential for operator safety.

Inherent Low Mechanical Strength

PTFE is not a structural plastic. It has a lower tensile strength than materials like nylon and is not suitable for applications requiring high mechanical loads or rigidity.

The Impact of Stress Creep

Even after a part is perfectly machined, it can slowly deform over time if it is subjected to a constant load. This phenomenon, known as stress creep, must be accounted for in the design phase if the part will be under any kind of compressive or tensile force.

Key Strategies for Successful PTFE Machining

Successfully machining PTFE requires adapting your approach to accommodate the material's unique behavior. The right strategy depends on your primary goal.

- If your primary focus is precision and tight tolerances: Use extremely sharp tools with high positive rake angles, slow feed rates, and a constant flood of water-soluble coolant to prevent any heat buildup.

- If your primary focus is a clean surface finish: Ensure your workpiece is securely supported to prevent vibration and use a very sharp tool to shear the material cleanly, minimizing burr formation.

- If your primary focus is safety and efficiency: Prioritize excellent workshop ventilation and a reliable cooling system to manage both the component's temperature and the risk of toxic fumes.

Ultimately, mastering the machining of PTFE comes from treating it with a light touch and understanding that its properties demand control over force and temperature above all else.

Summary Table:

| Challenge | Root Cause | Key Consequence |

|---|---|---|

| Dimensional Inaccuracy | High thermal expansion & softness | Part warps or deforms during/after machining |

| Poor Surface Finish | Material tears/smears instead of shearing | Heavy, stringy burrs are formed |

| Tool Chatter & Slippage | Low coefficient of friction | Tools slide, making clean cuts difficult |

| Safety Hazard | Poor thermal conductivity & decomposition >260°C (500°F) | Risk of toxic fume release |

Stop Struggling with PTFE Machining Challenges

Precision-machining PTFE components requires specialized expertise to overcome its unique properties. KINTEK specializes in the custom fabrication of high-quality PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors.

We leverage our deep material knowledge and advanced techniques to deliver parts that meet your tightest tolerances and performance requirements, from prototypes to high-volume production.

Let us handle the complexities for you. Contact KINTEK today to discuss your PTFE component needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Which solvents are highly resistant to Teflon encapsulated O-rings? Discover Their Superior Chemical Resistance

- How do FEP and PTFE encapsulated O-rings compare to traditional O-rings? A Hybrid Solution for Harsh Environments

- What are the typical characteristics and applications of O-ring materials? Find the Right Seal for Extreme Environments

- How can the disadvantages of PTFE processing machines be mitigated? Manage Trade-offs for Optimal Performance

- What are the characteristics of virgin PTFE bushings? Unlock Superior Chemical & Thermal Performance

- What role do PTFE expansion joints play in sustainable industrial practices? Reduce Waste and Emissions

- How does the working process affect PTFE Teflon O-rings? It Dictates Sealing Performance & Lifespan

- Why is a Teflon sheet essential for heat transfer projects? Ensure Perfect, Non-Stick Results