The primary benefits of using Teflon PTFE sheets are their exceptional non-stick surface, high heat resistance, and near-universal chemical inertness. These core properties make them incredibly versatile for applications ranging from industrial gaskets and electrical insulation to non-stick craft and baking surfaces.

The true value of a PTFE sheet isn't just its individual features, but how its unique molecular structure delivers a rare combination of solutions for problems involving extreme friction, temperature, and chemical exposure.

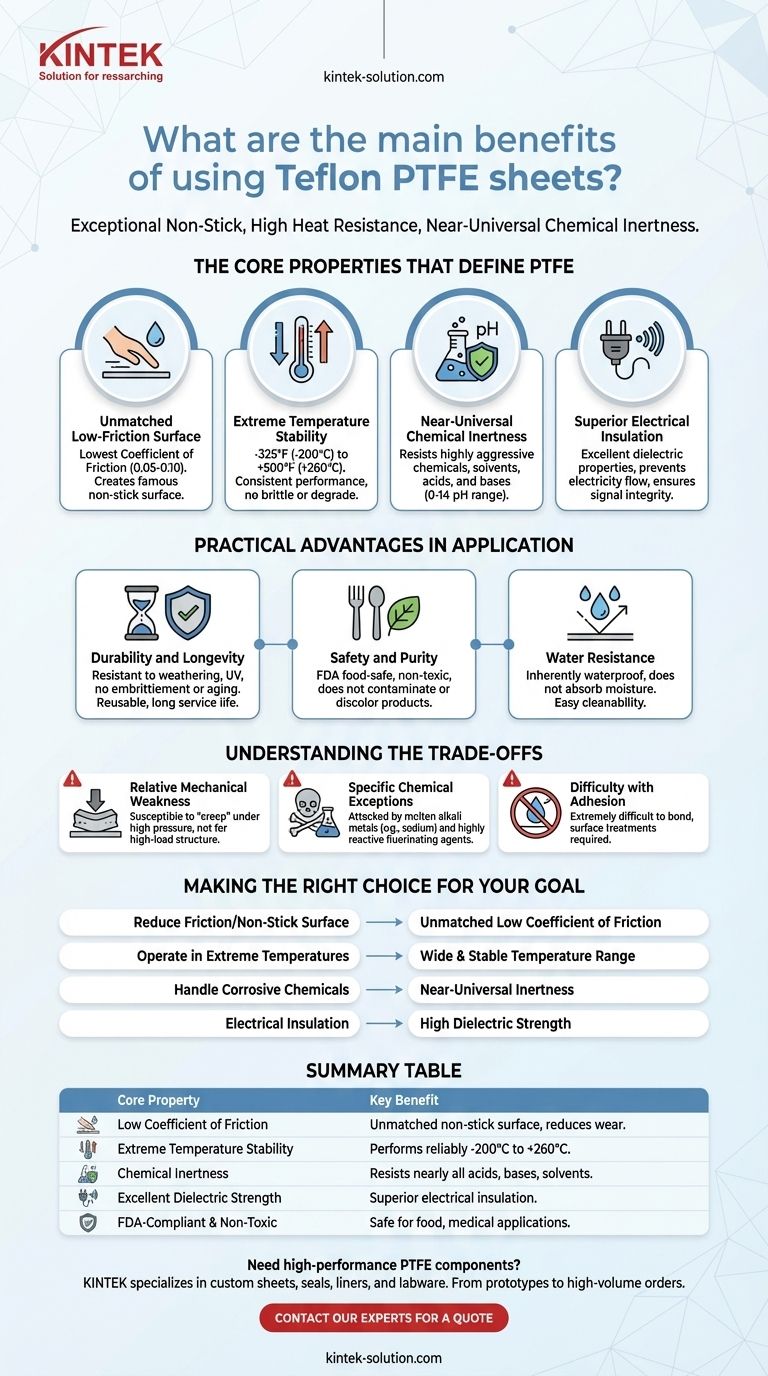

The Core Properties That Define PTFE

To understand the benefits of PTFE, we must look at its fundamental material characteristics. These properties are the reason it has become an essential material in countless demanding environments.

Unmatched Low-Friction Surface

PTFE possesses the lowest coefficient of friction of any known solid material, typically ranging from 0.05 to 0.10.

This extremely low friction is what creates its famous non-stick or non-adhesive quality, ensuring that most substances will not stick to its surface. This makes it ideal for easy cleanup in baking or preventing material buildup in industrial settings.

Extreme Temperature Stability

This material demonstrates remarkable performance across a vast temperature spectrum, operating reliably from cryogenic lows of -325°F (-200°C) up to continuous service temperatures of +500°F (+260°C).

This thermal stability means PTFE will not become brittle at low temperatures or degrade at high temperatures within this range, ensuring consistent performance.

Near-Universal Chemical Inertness

PTFE is one of the most chemically resistant materials available. It can withstand highly aggressive chemicals, solvents, acids, and bases across nearly the entire 0-14 pH range.

This property makes it indispensable for seals, liners, and gaskets in chemical processing, as it will not corrode, dissolve, or contaminate the end product.

Superior Electrical Insulation

As an outstanding electrical insulator with excellent dielectric properties, PTFE is used extensively in wiring, cables, and high-frequency electronics.

It effectively prevents the flow of electricity, ensuring signal integrity and safety in a wide variety of electrical applications.

Practical Advantages in Application

These core properties translate directly into tangible, real-world benefits that solve common engineering and design challenges.

Durability and Longevity

PTFE is highly resistant to weathering and does not degrade from UV exposure. The material is also stable over time, showing no embrittlement or aging.

This inherent durability, combined with its reusability in applications like baking sheets, leads to a long service life and excellent cost-effectiveness.

Safety and Purity

Many grades of PTFE are certified by the FDA as food-safe and are inherently non-toxic.

Because it is so inert, it does not contaminate or discolor the products it comes into contact with, a critical requirement for food, medical, and pharmaceutical industries.

Water Resistance

The material is inherently waterproof and does not absorb moisture. This hydrophobic nature contributes to its cleanability and stability in humid environments.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging PTFE's limitations is key to using it effectively.

Relative Mechanical Weakness

PTFE is a relatively soft material. Under high pressure, it can be susceptible to "creep" or "cold flow," meaning it can slowly deform over time. It is not suitable for high-load structural applications.

Specific Chemical Exceptions

While almost universally inert, PTFE is vulnerable to a few specific substances. It is attacked by molten alkali metals (like sodium) and highly reactive fluorinating agents like elemental fluorine.

Difficulty with Adhesion

The same non-stick property that makes PTFE so valuable also makes it extremely difficult to glue or bond to other materials. Surface treatments are typically required to achieve any meaningful adhesion.

Making the Right Choice for Your Goal

Select PTFE when its unique combination of properties directly addresses your primary challenge.

- If your primary focus is reducing friction or creating a non-stick surface: PTFE is the industry standard due to its unmatched low coefficient of friction.

- If your primary focus is operating in extreme temperatures: Its exceptionally wide and stable temperature range makes it a reliable choice for both heat and cold.

- If your primary focus is handling corrosive chemicals: Its near-universal inertness provides a safe and non-reactive barrier against almost any substance.

- If your primary focus is electrical insulation: Its high dielectric strength makes it one of the best insulators available for critical electronic components.

Ultimately, PTFE is a premier problem-solving material engineered to perform where other materials fail.

Summary Table:

| Core Property | Key Benefit |

|---|---|

| Low Coefficient of Friction | Unmatched non-stick surface, reduces wear and material buildup |

| Extreme Temperature Stability | Performs reliably from -200°C to +260°C |

| Chemical Inertness | Resists nearly all acids, bases, and solvents (0-14 pH) |

| Excellent Dielectric Strength | Superior electrical insulation for wiring and electronics |

| FDA-Compliant & Non-Toxic | Safe for food, medical, and pharmaceutical applications |

Need high-performance PTFE components for your application?

KINTEK specializes in manufacturing precision PTFE components—including custom sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We deliver custom fabrication from prototypes to high-volume orders, ensuring your solution meets the highest standards of durability and chemical resistance.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key properties that make Teflon rods suitable for industrial applications? Unlock Unmatched Chemical & Thermal Resistance

- Which industries commonly use PTFE Expansion Bellows? Solve Your Critical Chemical and Purity Challenges

- What are the key benefits of PTFE O-rings? Superior Sealing for Extreme Conditions

- Why is chemical inertness important for PTFE coated fasteners? Ensure Long-Term Reliability in Harsh Environments

- What role does temperature stability play in PTFE coated fasteners? Ensuring Reliability in Extreme Environments

- What is the function of check valves in water pump systems? Protect Your Pump and Prevent Backflow

- How should one choose the right packing material? A Guide to Maximizing Seal Performance and Lifespan

- How does PTFE's non-stick property benefit wire and cable design? Enable Compact, Flexible, and Durable Cables