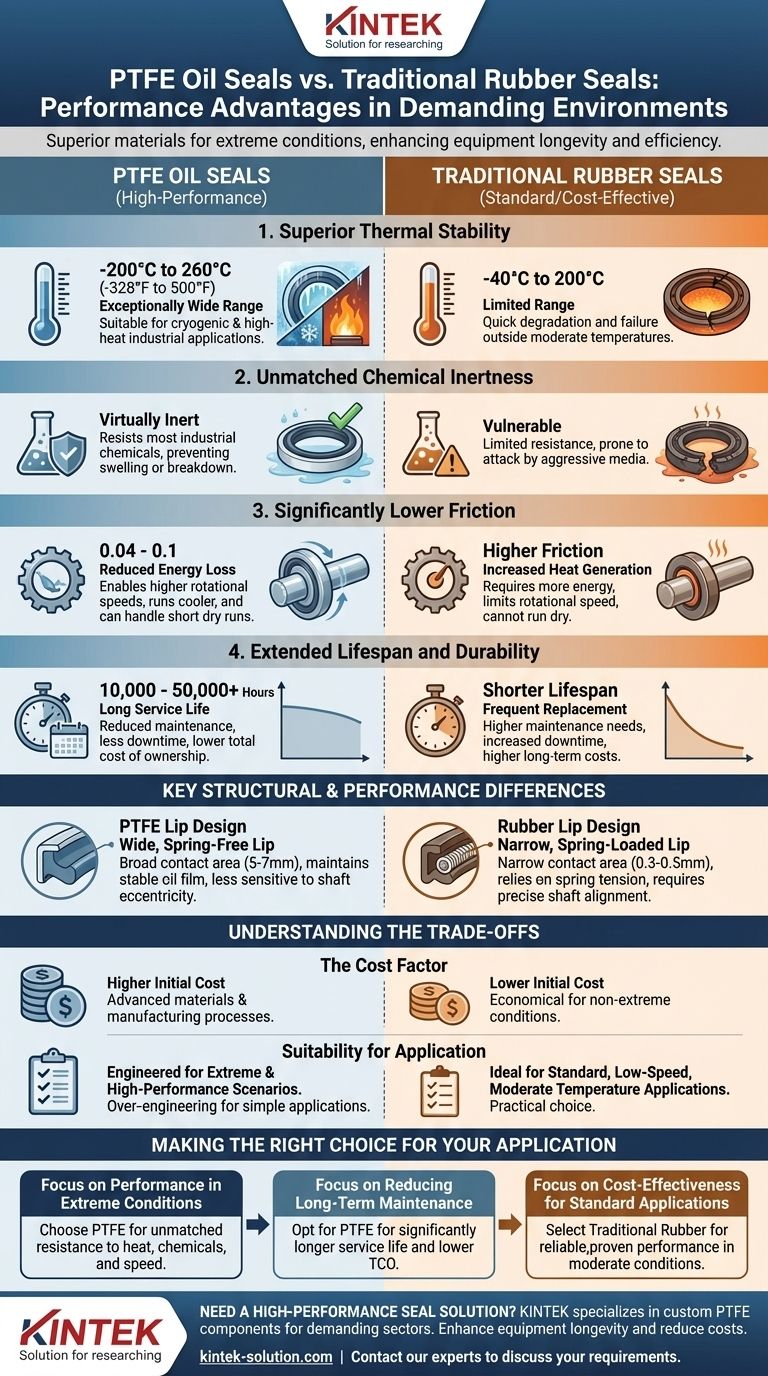

When operating in demanding environments, PTFE oil seals offer significant performance advantages over traditional rubber seals. Their superiority stems from fundamental material properties, providing unmatched resistance to extreme temperatures and aggressive chemicals, a lower coefficient of friction for higher efficiency, and a substantially longer operational lifespan.

The choice between PTFE and rubber is not merely a material preference; it's a strategic decision based on the application's intensity. PTFE is engineered for resilience in extreme conditions, while rubber remains the cost-effective standard for less demanding, common applications.

Why PTFE Excels in Harsh Environments

The core advantages of Polytetrafluoroethylene (PTFE) are most apparent when a system pushes the operational limits of conventional materials.

Superior Thermal Stability

PTFE seals operate effectively across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This makes them suitable for everything from cryogenic applications to high-heat industrial machinery, environments where traditional rubber seals (typically rated -40°C to 200°C) would quickly degrade and fail.

Unmatched Chemical Inertness

PTFE is virtually inert to most industrial chemicals and solvents. This exceptional chemical resistance prevents the seal from swelling, hardening, or breaking down when exposed to aggressive fluids, ensuring long-term integrity.

Significantly Lower Friction

With a very low coefficient of friction (0.04 to 0.1), PTFE seals generate less heat and require less energy to operate.

This reduces energy loss, allows for higher rotational speeds, and even enables the seal to run dry for short periods in emergency conditions without catastrophic failure.

Extended Lifespan and Durability

The combination of thermal, chemical, and wear resistance gives PTFE seals a much longer service life, often between 10,000 and 50,000 hours.

This extended lifespan directly translates to reduced maintenance, less downtime, and a lower total cost of ownership for critical equipment.

Key Structural and Performance Differences

The design philosophy behind PTFE seals is fundamentally different from that of traditional rubber seals, leading to distinct performance characteristics.

The Lip Design Principle

Traditional rubber seals rely on a spring-loaded, sharp lip with a very narrow contact area (0.3-0.5mm) to create a tight seal.

In contrast, PTFE seals typically use a spring-free, wide lip dynamic structure. The contact surface is much broader (5-7mm), which changes how the seal interacts with the shaft.

Impact on Oil Film and Shaft Stability

The wider lip of a PTFE seal is designed to maintain a sufficient and stable oil film between the seal and the shaft.

This design is also less sensitive to shaft eccentricity or "runout," providing a more reliable seal in real-world machinery where perfect alignment is not always possible.

Understanding the Trade-offs

While PTFE offers superior performance in many areas, it is not the universal solution. Objectivity requires acknowledging where traditional seals still hold value.

The Cost Factor

The primary advantage of rubber oil seals is their lower initial cost. The advanced properties and manufacturing processes of PTFE make it a more expensive material.

For applications without extreme conditions, a rubber seal often provides sufficient performance at a more economical price point.

Suitability for the Application

PTFE is engineered for high-performance scenarios. Using a PTFE seal in a simple, low-speed, static application with moderate temperatures may be unnecessary over-engineering.

In these common situations, a standard rubber seal performs reliably and is the more practical and cost-effective choice.

Making the Right Choice for Your Application

Selecting the correct seal material is critical for ensuring system reliability and managing costs. Your decision should be guided by the specific demands of your operating environment.

- If your primary focus is performance in extreme conditions: Choose PTFE for its unmatched resistance to high temperatures, aggressive chemicals, and high-speed operation.

- If your primary focus is reducing long-term maintenance: Opt for PTFE due to its significantly longer service life, which lowers the total cost of ownership in critical systems.

- If your primary focus is cost-effectiveness for standard applications: Select traditional rubber seals, as they provide reliable, proven performance in moderate conditions at a lower initial cost.

Ultimately, selecting the right seal requires a clear understanding of your specific operational demands and long-term goals.

Summary Table:

| Feature | PTFE Oil Seals | Traditional Rubber Seals |

|---|---|---|

| Temperature Range | -200°C to 260°C | -40°C to 200°C |

| Chemical Resistance | Exceptional (Virtually Inert) | Limited |

| Coefficient of Friction | Very Low (0.04-0.1) | Higher |

| Typical Lifespan | 10,000 - 50,000 hours | Shorter |

| Best For | Extreme temperatures, chemicals, high speeds | Standard, cost-sensitive applications |

Need a high-performance seal for a demanding application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. Whether you require prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures a reliable seal solution that enhances equipment longevity and reduces your total cost of ownership.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C