In demanding industrial applications, the primary advantages of expanded PTFE (ePTFE) gaskets are their near-universal chemical resistance, an extremely wide operational temperature range, and a unique ability to conform to and seal imperfect surfaces. Unlike rigid gaskets, the "expanded" nature of the material gives it a soft, flexible structure that creates a highly reliable seal even under difficult conditions.

The crucial takeaway is that the expansion process transforms standard, rigid PTFE into a soft, highly conformable material. This allows it to solve the real-world problem of sealing irregular or damaged flange surfaces without sacrificing the exceptional chemical and thermal resistance inherent to PTFE.

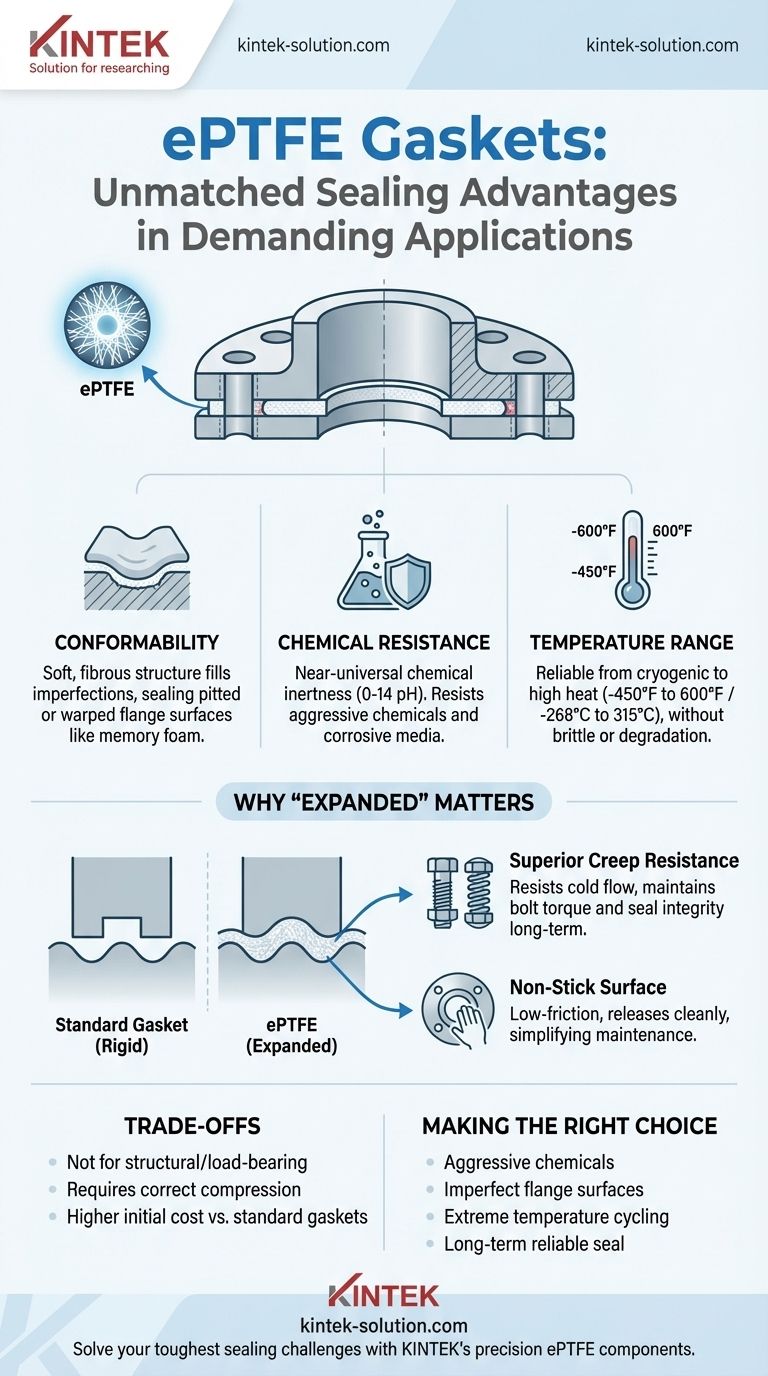

Why "Expanded" PTFE Is a Game-Changer

Standard gaskets often struggle to create a perfect seal on flanges that are not perfectly flat. Real-world equipment can have minor pitting, scratches, or warping, which are common points of failure for less forgiving materials. Expanded PTFE is engineered specifically to overcome this challenge.

The Power of Conformability

The manufacturing process for ePTFE creates a multidirectional fibrous structure. This gives the material excellent flexibility and plasticity, allowing it to flow into the small imperfections of a flange surface when compressed.

Think of it like the difference between a wooden block and a memory foam pad. The wooden block can only seal a perfectly flat surface, while the memory foam will conform to any shape, filling every gap and ensuring a complete seal.

Superior Resistance to Creep and Cold Flow

A common failure point for standard PTFE is creep, or cold flow, where the material deforms permanently under pressure over time. This leads to a loss of bolt torque and, eventually, a leak.

Expanded PTFE has a fibrous structure that actively resists this phenomenon. It maintains its form and elasticity under load, ensuring the initial bolt tightening force is preserved for a much longer, more reliable service life.

Core Chemical and Thermal Advantages

Beyond its unique physical structure, ePTFE retains all the powerful inherent benefits of the base PTFE material, making it suitable for the most extreme industrial services.

Unmatched Chemical Inertness

Expanded PTFE is resistant to virtually all chemicals across the entire 0-14 pH range. The only exceptions are molten alkali metals and elemental fluorine. This makes it a go-to solution for sealing aggressive and corrosive media in chemical processing, pharmaceuticals, and manufacturing.

Extreme Temperature Resilience

ePTFE gaskets perform reliably across an exceptionally broad temperature spectrum, typically from -450°F to 600°F (-268°C to 315°C). This stability prevents the material from becoming brittle at cryogenic temperatures or degrading in high-heat applications, ensuring a consistent seal during thermal cycling.

A Low-Friction, Non-Stick Surface

The material possesses a very low coefficient of friction. This non-stick property means that after service, the gasket releases cleanly from flange surfaces without leaving residue. This simplifies maintenance, reduces cleaning time, and helps extend the life of the flanges themselves.

Understanding the Trade-offs

While highly effective, ePTFE is not a universal solution. Understanding its limitations is key to using it correctly and avoiding misapplication.

Not for Structural Applications

Expanded PTFE is a soft, pliable sealing material. It is not designed for applications that require high tensile strength or structural rigidity. It is purely a sealing interface and cannot serve as a load-bearing component.

Requires Correct Compression

The effectiveness of an ePTFE gasket is dependent on achieving the correct compressive load. Insufficient bolt torque will fail to properly seat the gasket and fill surface imperfections. Conversely, extreme over-tightening can damage the gasket's porous structure. Always follow the manufacturer's torque specifications.

Higher Initial Cost

As a high-performance, specialized material, ePTFE gaskets typically have a higher upfront cost than common fiber or elastomer gaskets. However, this cost is often justified by reduced maintenance, longer service life, and prevention of costly leaks in critical applications.

Making the Right Choice for Your Goal

Selecting the right gasket comes down to matching the material's strengths to the specific demands of the application.

- If your primary focus is sealing aggressive chemicals: ePTFE's near-universal chemical inertness provides the most reliable long-term seal against corrosive media.

- If you are dealing with older or imperfect flange surfaces: Its exceptional conformability will fill in pits, scratches, and warps where more rigid gaskets would fail.

- If your application involves extreme temperature cycling: ePTFE maintains its integrity and sealing properties across a vast temperature range, preventing leaks caused by material degradation.

- If you need to maintain a reliable seal over a long service life: Its superior resistance to creep ensures the bolt load remains stable, drastically reducing the need for re-torquing.

By understanding its unique ability to conform without compromise, you can specify ePTFE with confidence for your most critical sealing challenges.

Summary Table:

| Key Advantage | Description |

|---|---|

| Conformability | Soft, fibrous structure seals imperfect, pitted, or warped flange surfaces. |

| Chemical Resistance | Resistant to virtually all chemicals (0-14 pH), except molten alkali metals and fluorine. |

| Temperature Range | Performs reliably from -450°F to 600°F (-268°C to 315°C). |

| Creep Resistance | Fibrous structure resists cold flow, maintaining bolt load and seal integrity long-term. |

| Non-Stick Surface | Low friction allows for clean removal, simplifying maintenance and protecting flanges. |

Solve your toughest sealing challenges with KINTEK's precision ePTFE components.

For semiconductor, medical, laboratory, and industrial applications, a reliable seal is critical. Our expanded PTFE gaskets, seals, and custom fabrications are engineered to deliver unmatched chemical resistance, thermal stability, and conformability—even on imperfect surfaces.

We specialize in creating high-performance solutions, from prototypes to high-volume orders, ensuring your equipment operates safely and efficiently.

Contact KINTEK today to discuss your specific requirements and get a quote for a sealing solution you can depend on.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation