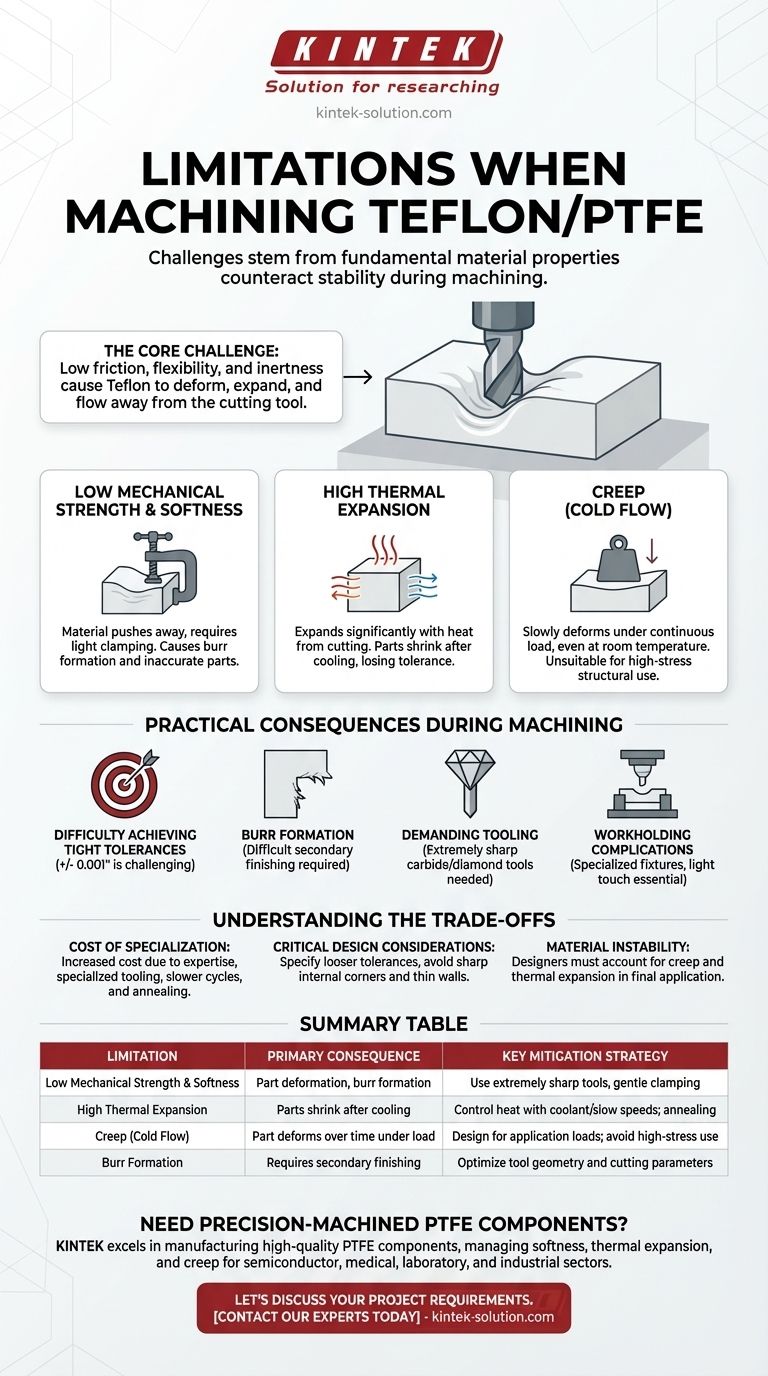

Machining Teflon (PTFE) is primarily limited by its fundamental material properties. Its softness, low mechanical strength, high thermal expansion rate, and tendency to deform under pressure (creep) create significant challenges. These factors combine to make achieving and holding tight dimensional tolerances far more difficult than with metals or more rigid polymers.

The core challenge of machining Teflon is that the very properties that make it uniquely useful in application—low friction, flexibility, and chemical inertness—are the same properties that cause it to deform, expand, and flow away from the cutting tool during manufacturing.

The Core Challenge: Why Teflon Fights the Machining Process

To machine a part successfully, the material must be stable. It needs to hold its shape under clamping pressure and resist the heat and force of the cutting tool. Teflon’s inherent nature works against this stability in several key ways.

Low Mechanical Strength and Softness

Teflon is an exceptionally soft material. When a cutting tool applies force, the material can easily deform or push away rather than shearing cleanly.

This softness also means it cannot be clamped tightly in a machine vise. Excessive clamping pressure will crush or distort the raw material, leading to inaccurate final parts. This also directly causes the formation of burrs, thin ridges of unwanted material that must be removed in a secondary operation.

High Thermal Expansion

PTFE has a very high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. The friction from a cutting tool generates localized heat.

Because Teflon is also a poor thermal conductor, this heat doesn't dissipate quickly. The area being machined gets hot, expands, and is cut to size. Once the part cools to room temperature, it shrinks and may no longer be within the required tolerance.

Creep and Cold Flow

Creep, or "cold flow," is Teflon's tendency to slowly and permanently deform when subjected to a continuous load, even at room temperature.

This means a part can be dimensionally accurate immediately after machining, but if it is subjected to clamping pressure or even its own weight in certain orientations, it can slowly change shape over time. This makes it unsuitable for many high-load structural applications.

Practical Consequences During Machining

These material properties translate directly into tangible problems on the shop floor, requiring specialized knowledge and equipment to overcome.

Difficulty Achieving Tight Tolerances

This is the single greatest consequence. The combination of thermal expansion, deformation under tool pressure, and stress from clamping makes precision difficult. Holding a tolerance of +/- 0.001 inches on Teflon is a significant challenge, whereas it is routine for metals.

Burr Formation

The material’s softness means it is often pushed or smeared by the cutting tool rather than being cut cleanly. This results in significant burrs on part edges that are difficult and time-consuming to remove without damaging the part's surface.

Demanding Tooling Requirements

Machining Teflon effectively requires extremely sharp cutting tools, often made of carbide or featuring diamond tips. A dull tool will exacerbate the material's tendency to deform and smear, leading to a poor surface finish and dimensional inaccuracy. These sharp tools can also wear quickly depending on the specific grade of PTFE being used.

Workholding Complications

You cannot secure a block of Teflon with the same force used for aluminum or steel. Machinists must use specialized fixtures or a very light touch to hold the material securely without introducing stress or distortion that will ruin the final part.

Understanding the Trade-offs

Choosing to machine a Teflon part involves accepting a distinct set of compromises related to cost, design, and manufacturing complexity.

The Cost of Specialization

Successfully machining Teflon requires operator expertise, specialized tooling, and often slower cycle times to manage heat buildup. Processes like annealing (a controlled heating and cooling cycle to relieve internal stress) may be necessary before and after machining to ensure stability. These factors inevitably increase the cost per part.

Critical Design Considerations

Engineers must design for Teflon's limitations. This means specifying realistic, looser tolerances wherever possible. Features like razor-sharp internal corners, extremely thin walls, or complex geometries that are easy to create in more rigid materials may be impractical or impossible to produce accurately in Teflon.

Material Instability is a Given

Unlike a metal part, a machined Teflon component is never perfectly stable. Designers and engineers must account for creep and thermal expansion in the final assembly and application environment. What works on a lab bench at 70°F may not work in the field at 100°F.

How to Ensure a Successful PTFE Machining Project

To mitigate these limitations, your approach must be guided by your project's most critical requirement.

- If your primary focus is dimensional accuracy: Specify pre- and post-machining annealing, work with a machine shop that has deep experience with soft polymers, and ensure they use sharp tooling and liquid coolant.

- If your primary focus is structural integrity: Design parts with generous wall thicknesses and corner radii, avoid thin or unsupported features, and understand that Teflon should not be used for high-load, stress-bearing applications.

- If your primary focus is cost-effectiveness: Loosen tolerances as much as your application will allow, simplify the part geometry, and discuss material selection with your manufacturing partner to see if a more machinable polymer could meet your needs.

Ultimately, successfully using machined Teflon requires balancing its unparalleled performance in the right application with the deliberate and expert approach needed to manufacture it correctly.

Summary Table:

| Limitation | Primary Consequence | Key Mitigation Strategy |

|---|---|---|

| Low Mechanical Strength & Softness | Part deformation, burr formation, difficult clamping | Use extremely sharp tools, specialized fixtures, gentle clamping |

| High Thermal Expansion | Parts shrink after cooling, losing tolerance | Control heat with coolant/slow speeds; pre/post-machine annealing |

| Creep (Cold Flow) | Part deforms over time under sustained load | Design for application loads; avoid high-stress structural uses |

| Burr Formation | Requires secondary finishing, increases cost/time | Optimize tool geometry and cutting parameters |

Need Precision-Machined PTFE Components?

Navigating the challenges of machining Teflon requires a partner with specialized expertise. At KINTEK, we excel at manufacturing high-quality PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand how to manage softness, thermal expansion, and creep to deliver the dimensional stability your application demands. Whether you need prototypes or high-volume production, our precision production and custom fabrication capabilities ensure your project is a success.

Let's discuss your project requirements. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers