To be direct, the primary limitations of PTFE envelope gaskets stem from their hybrid construction. While offering superb chemical resistance, they are sensitive to installation errors, can deform under load (a phenomenon known as creep), and have a higher thermal expansion rate than the metal flanges they seal, creating potential challenges in certain operating conditions.

The core trade-off with a PTFE envelope gasket is accepting specific mechanical and installation vulnerabilities in exchange for near-universal chemical inertness and product purity. Understanding these limitations is the key to deploying them successfully.

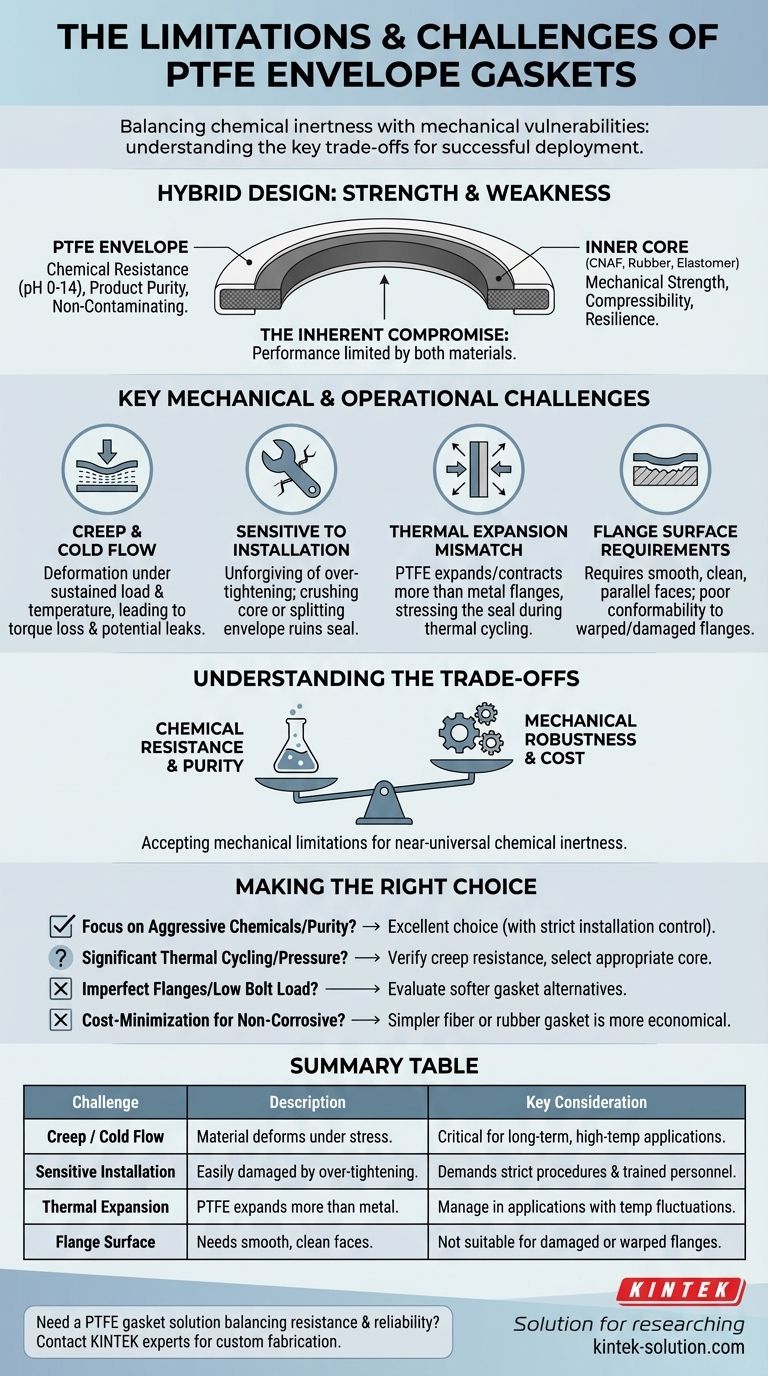

The Hybrid Design: Source of Strength and Weakness

To understand the challenges of PTFE envelope gaskets, you must first understand their structure. They are not made of solid PTFE but are a composite of two distinct materials.

The PTFE Envelope

The outer layer, or "envelope," is a thin sheet of polytetrafluoroethylene (PTFE). This layer is what contacts the process fluid.

This envelope provides the gasket's signature benefit: exceptional resistance to virtually all chemicals across the entire pH range (0-14) and a non-contaminating surface ideal for food, beverage, and pharmaceutical applications.

The Inner Core

Inside the envelope is a core material, often made of compressed non-asbestos fiber (CNAF), rubber, or another elastomer.

This core provides the mechanical strength, compressibility, and resilience that pure, solid PTFE lacks. It gives the gasket the "body" needed to create and maintain a seal under pressure.

The Inherent Compromise

This two-part design is an intelligent compromise. However, it means the gasket's performance is limited by the properties of both the PTFE envelope and the inner core, creating specific vulnerabilities you must account for.

Key Mechanical and Operational Challenges

The composite nature of these gaskets leads to several well-defined challenges that require careful management during design and installation.

Creep and Cold Flow

While the core improves mechanical stability, the PTFE envelope itself is still susceptible to creep or cold flow.

This is the tendency of the material to slowly deform over time when subjected to sustained mechanical stress, especially at elevated temperatures. This can lead to a loss of bolt torque and a potential leak path.

Sensitivity to Installation

This is perhaps the most critical challenge. PTFE envelope gaskets are far less forgiving of improper installation than many other gasket types.

Over-tightening is a common failure mode. Excessive bolt load can crush the inner core or split the thin PTFE envelope, destroying the gasket's chemical resistance and creating an immediate leak.

Thermal Expansion Mismatch

PTFE has a significantly higher coefficient of thermal expansion than the steel or other metals used for flanges.

During thermal cycling (heating and cooling), the gasket will expand and contract more than the flanges. This differential movement can stress the seal and may require re-torquing or specialized bolt-loading procedures to prevent leaks.

Flange Surface Requirements

The thin, relatively hard PTFE surface requires a smooth, clean, and parallel flange face to achieve an effective seal.

These gaskets are not well-suited for sealing flanges that are warped, scarred, or have significant surface imperfections, as they lack the conformability of softer, more malleable materials.

Performance in Low Bolt Load

Depending on the core material chosen, some PTFE envelope gaskets require a substantial bolt load to properly "seat" and create a seal.

In applications with limited available bolt load, they may not compress sufficiently, resulting in poor sealing efficiency compared to softer, more compliant gasket types.

Understanding the Trade-offs

Choosing a gasket is always an exercise in balancing competing priorities. The PTFE envelope gasket is no exception.

Chemical Resistance vs. Mechanical Robustness

You are selecting this gasket for its unparalleled chemical compatibility. The trade-off is a narrower operational window for temperature, pressure, and mechanical stress compared to metallic or semi-metallic gaskets.

Cost vs. Long-Term Value

PTFE envelope gaskets are more expensive upfront than many standard elastomeric or fiber gaskets. Their value is justified in applications where preventing chemical attack, ensuring product purity, and achieving long service life in corrosive environments are the primary goals.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE envelope gasket is the correct solution for your specific goal.

- If your primary focus is handling aggressive chemicals or ensuring product purity: This gasket is an excellent choice, provided you can strictly control the installation process and operate within its specified mechanical limits.

- If your application involves significant thermal cycling or pressure fluctuations: You must carefully select the core material and verify that the gasket's creep resistance is sufficient for your long-term needs.

- If you have imperfect flange surfaces or low available bolt load: You should evaluate whether a different gasket type, such as one with a softer material, might provide a more reliable and forgiving seal.

- If your primary focus is cost-minimization for a non-corrosive, standard utility service: A simpler compressed fiber or rubber gasket is almost certainly a more economical and appropriate choice.

Ultimately, a PTFE envelope gasket is a high-performance solution for demanding chemical applications, and its successful use depends on respecting its unique mechanical characteristics.

Summary Table:

| Challenge | Description | Key Consideration |

|---|---|---|

| Creep / Cold Flow | Material deforms under sustained stress, leading to potential seal loss. | Critical for long-term, high-temperature applications. |

| Sensitive Installation | Easily damaged by over-tightening; requires precise bolt load. | Demands strict installation procedures and trained personnel. |

| Thermal Expansion Mismatch | PTFE expands/contracts more than metal flanges during thermal cycling. | Requires careful management in applications with temperature fluctuations. |

| Flange Surface Requirements | Needs smooth, clean, and parallel flange faces for an effective seal. | Not suitable for damaged or warped flanges. |

Need a PTFE gasket solution that balances chemical resistance with mechanical reliability?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets. We understand the critical balance between chemical inertness and mechanical stability. Our expertise ensures your gaskets are designed and fabricated to meet the specific demands of your application, whether you're in the semiconductor, medical, laboratory, or industrial sector.

We provide custom fabrication from prototypes to high-volume orders, prioritizing precision to help you overcome challenges like creep and installation sensitivity.

Let's engineer a solution for your specific sealing challenge. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries