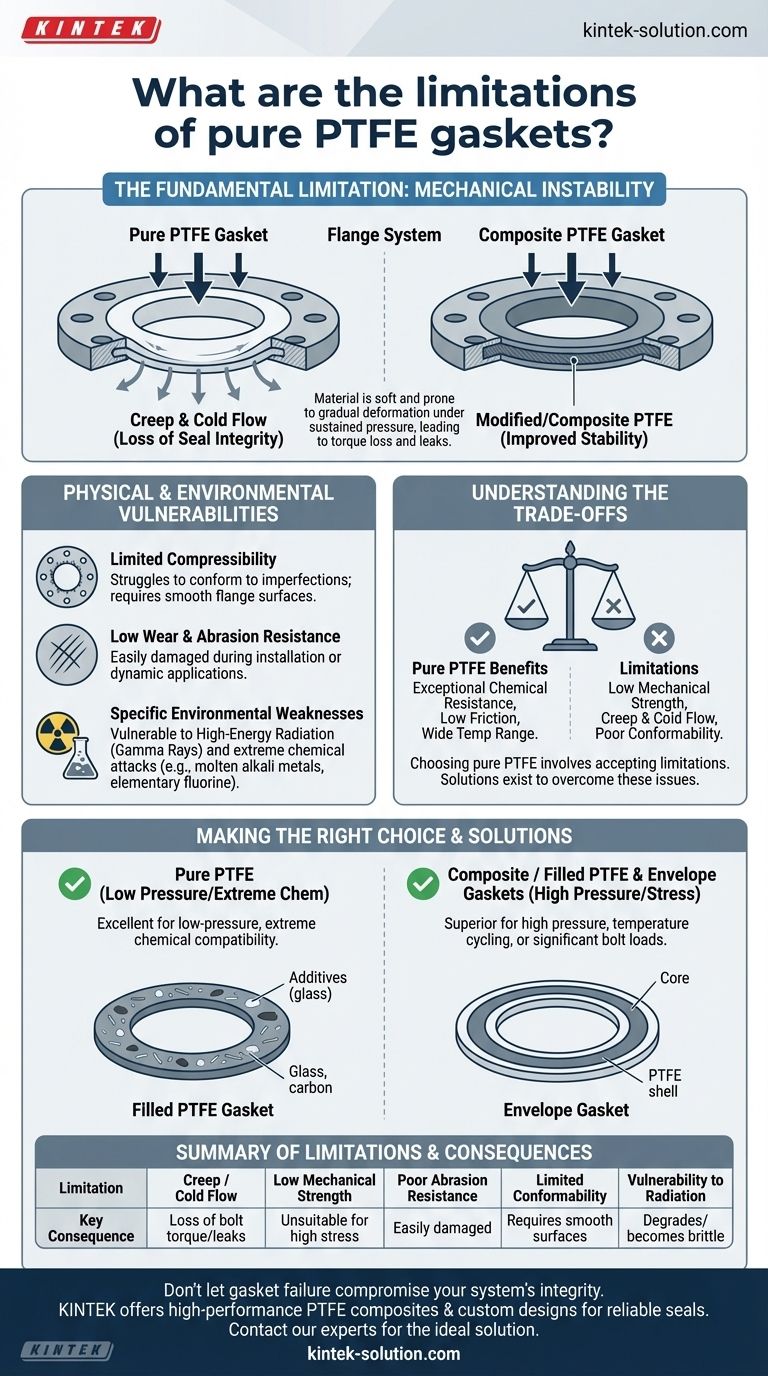

The fundamental limitation of pure PTFE gaskets is their inherent mechanical weakness. While valued for chemical inertness, the material is relatively soft and prone to gradual deformation under sustained pressure, a phenomenon known as creep or cold flow. This can lead to a loss of bolt torque and sealing integrity over time, especially in demanding applications.

While pure PTFE offers almost universal chemical resistance, its softness and tendency to deform under load make it unsuitable for high-pressure or structurally demanding systems. The solution is often not to abandon PTFE, but to use a modified or composite version that adds mechanical strength while retaining its chemical inertness.

The Core Challenge: Mechanical Instability

The primary drawbacks of using a gasket made from 100% pure PTFE stem from its physical properties as a polymer. It is not designed for high mechanical stress.

Understanding Creep and Cold Flow

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress. Cold flow is a specific form of creep that can occur at room temperature.

For pure PTFE gaskets, this means the material can slowly "flow" out from between the flanges after the bolts are torqued. This reduces the sealing pressure and can eventually create a leak path.

Limited Compressibility

Pure PTFE is not highly compressible. This means it struggles to conform to and fill in minor imperfections, scratches, or irregularities on flange surfaces.

This lack of "give" requires smoother, more perfect flange faces to achieve an effective seal compared to more resilient gasket materials.

Low Wear and Abrasion Resistance

The softness of pure PTFE also results in poor resistance to abrasion and wear. In dynamic applications or during installation, the material can be easily scratched or damaged, compromising its sealing capability.

Environmental and Chemical Vulnerabilities

While known for its exceptional resistance, PTFE is not invincible and has specific weaknesses under certain environmental conditions.

High-Energy Radiation Breakdown

PTFE has poor resistance to high-energy radiation, such as gamma rays. This type of radiation can break down the polymer's molecular structure, causing it to lose its beneficial properties and become brittle.

Chemical Attack Under Extreme Conditions

Although resistant to most chemicals, pure PTFE can be attacked by a few highly reactive agents, particularly at high pressures and temperatures.

These include elementary fluorine, chlorine trifluoride, and molten alkali metals. These are niche exceptions but are critical to note for specialized industrial processes.

Understanding the Trade-offs

Choosing pure PTFE involves accepting its limitations in exchange for its benefits. Understanding these trade-offs is key to preventing system failure.

Fabrication and Installation Constraints

Pure PTFE cannot be easily cemented or welded, which can limit how gaskets are fabricated or repaired. This makes it less versatile for creating complex, monolithic custom shapes compared to other materials.

The Pure PTFE vs. Composite PTFE Decision

The mechanical weaknesses of pure PTFE are well-understood. For this reason, many gaskets use a modified form to overcome these issues.

Filled PTFE includes additives like glass, carbon, or graphite to dramatically improve creep resistance and mechanical strength. Envelope gaskets use a resilient core material (like rubber or non-asbestos fiber) wrapped in a thin PTFE shell, combining the strength of the core with the chemical resistance of the shell.

Making the Right Gasket Choice

Selecting the correct gasket requires matching the material's properties to the application's demands.

- If your primary focus is extreme chemical compatibility in a low-pressure system: Pure PTFE is an excellent and often necessary choice.

- If your application involves high pressure, temperature cycling, or significant bolt loads: A filled or PTFE envelope gasket is the superior technical solution.

- If your flanges have minor imperfections or you need a more forgiving seal: A PTFE envelope gasket with a compressible core is far more reliable than pure PTFE.

Choosing the right gasket is a critical engineering decision that directly impacts the safety and reliability of your entire system.

Summary Table:

| Limitation | Key Consequence |

|---|---|

| Creep / Cold Flow | Loss of bolt torque and sealing pressure over time, leading to leaks. |

| Low Mechanical Strength | Unsuitable for high-pressure or high-stress applications. |

| Poor Abrasion Resistance | Easily damaged during installation or in dynamic applications. |

| Limited Conformability | Requires very smooth, flat flange surfaces for an effective seal. |

| Vulnerability to Radiation | Degrades and becomes brittle when exposed to gamma rays. |

Don't let gasket failure compromise your system's integrity. The limitations of pure PTFE are well-known, but the solution is clear: a high-performance PTFE composite or custom design. KINTEK manufactures precision PTFE components (seals, liners, labware) for semiconductor, medical, laboratory, and industrial applications. We prioritize performance and offer custom fabrication from prototypes to high-volume orders to ensure your system is safe and reliable. Contact our experts today to discuss the ideal PTFE solution for your specific pressure, chemical, and temperature requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are PTFE bushes and where are they commonly used? Solve Friction, Chemical, and Temperature Challenges

- What are the typical applications of PTFE bearing pads? Managing Movement in Bridges and Large Structures

- What are the key features of encapsulated O-rings designed for chemical resistance? Achieve Superior Sealing in Harsh Environments

- What are the common product forms of Teflon? A Guide to PTFE Sheets, Tapes, Coatings & More

- What are the nonstick properties of PTFE? Unlocking Superior Performance for Demanding Applications

- What are the advantages of PTFE-coated O-rings? Reduce Friction & Color-Code for Easy Assembly

- How do PTFE lined valves provide excellent chemical resistance? The Ultimate Guide to Inert Fluid Handling

- What guidelines apply to machining oil grooves in PTFE pads? Achieve Precision & Avoid Common Pitfalls