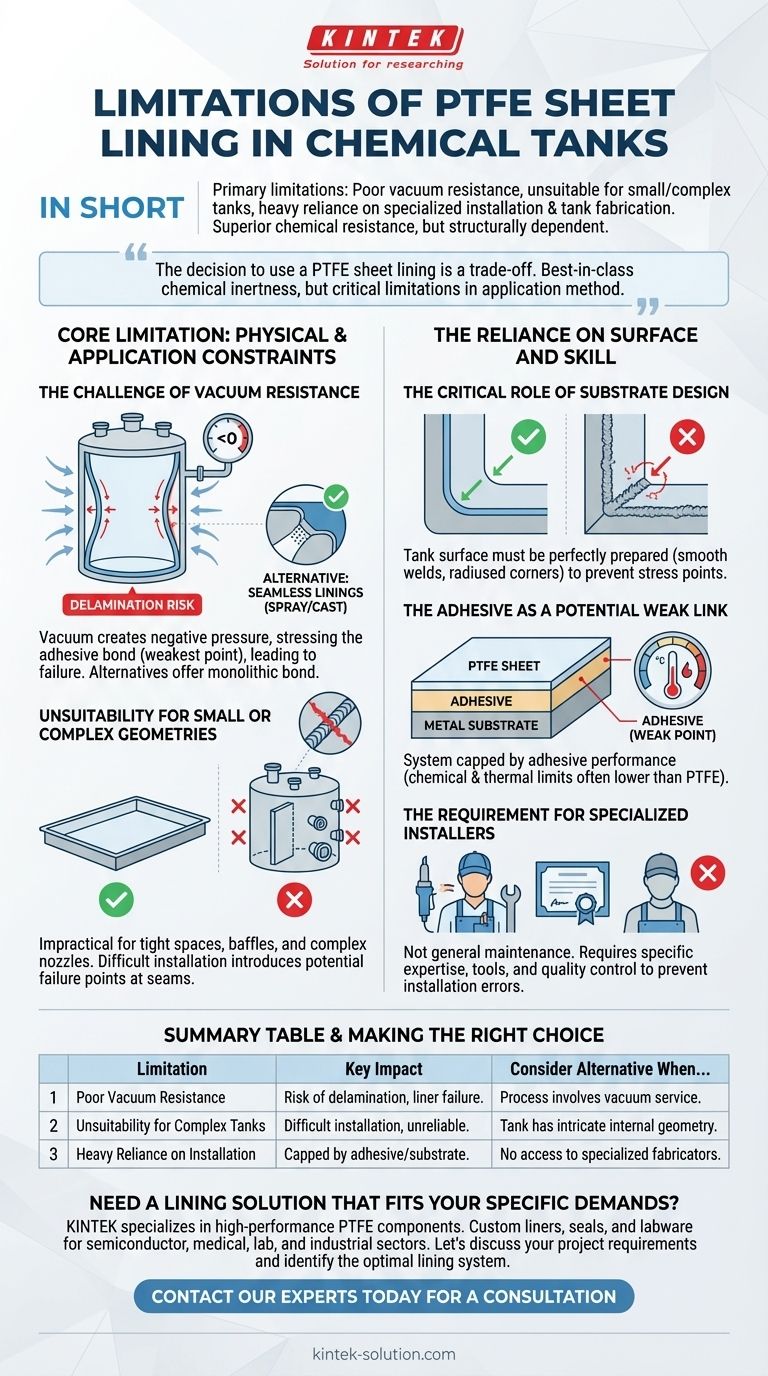

In short, the primary limitations of PTFE sheet lining are its poor vacuum resistance, its unsuitability for small or geometrically complex tanks, and its heavy reliance on specialized installation and proper tank fabrication. While it offers superior chemical resistance, its effectiveness is entirely dependent on these structural and application-specific factors.

The decision to use a PTFE sheet lining is a trade-off. You gain best-in-class chemical inertness, but you accept critical limitations related to the physical application method, making it a specialized solution rather than a universal one.

Core Limitation: Physical and Application Constraints

Unlike the material properties of PTFE itself, its biggest drawbacks emerge from the method of applying it as a bonded sheet inside a vessel.

The Challenge of Vacuum Resistance

PTFE sheet linings are adhered to the tank's inner wall. A vacuum condition inside the tank creates a negative pressure differential, which actively pulls the liner away from the substrate.

This places immense stress on the adhesive bond, which is often the weakest point in the system. Over time, this can lead to delamination, bubbling, and catastrophic liner failure. In contrast, spray-applied or centrifugally cast linings have a more monolithic bond and perform significantly better under vacuum.

Unsuitability for Small or Complex Geometries

Applying a pre-fabricated sheet to a surface is straightforward on large, flat, or simply-curved areas. However, this method becomes impractical and unreliable for small tanks or those with intricate internal structures like baffles or complex nozzles.

Cutting, fitting, and welding sheets in tight spaces is difficult and introduces numerous potential points of failure at the seams.

The Reliance on Surface and Skill

A PTFE sheet lining is not a standalone component; it is part of a system. The success of that system depends entirely on the quality of the tank it is adhered to and the expertise of the installers.

The Critical Role of Substrate Design

The steel tank is not just a container; it is the foundation for the lining. The surface must be perfectly prepared, with smooth welds and properly radiused corners, to prevent stress points in the liner.

Any imperfection in the tank's fabrication can compromise the adhesive bond or create a weak spot in the PTFE sheet, leading to premature failure. This is why proper tank design is non-negotiable for this method.

The Adhesive as a Potential Weak Link

The entire system relies on the adhesive that bonds the surface-treated PTFE sheet to the metal. This adhesive has its own chemical and thermal resistance limits, which may be lower than those of the PTFE itself.

The performance of the entire lined tank is therefore capped by the performance of the adhesive used.

The Requirement for Specialized Installers

Applying PTFE sheet linings is not a general maintenance task; it is a highly specialized trade. It requires specific knowledge, tools, and quality control procedures to properly prepare the surface, apply the adhesive, and weld the seams.

Relying on specialized companies is essential, as improper installation is a leading cause of liner failure.

Understanding the Trade-offs

No single lining solution is perfect for every application. Choosing the right one requires an objective look at the compromises involved.

When to Choose PTFE Sheet Lining

Despite its limitations, PTFE sheet lining is an excellent choice for large, simple-geometry tanks that require elite-level resistance to aggressive chemicals and acids. In these scenarios, its chemical inertness is unmatched.

When to Consider Alternatives

For applications involving vacuum service, small tanks, or vessels with complex internal geometry, other methods are superior.

Spray-applied or centrifugally cast linings offer a seamless, monolithic bond to the tank wall. This makes them inherently better at handling vacuum and more adaptable to intricate shapes.

Making the Right Choice for Your Application

Your decision must be driven by the specific demands of your process and equipment.

- If your primary focus is maximum chemical resistance for a large, simple tank with no vacuum service: PTFE sheet lining is a top-tier solution, provided you partner with an expert installer and ensure proper tank fabrication.

- If your application involves vacuum, a small tank, or complex internal geometry: You should immediately investigate alternatives like spray-applied or centrifugally cast linings, which are better suited to these mechanical stresses.

- If you are working with a strict budget or timeline: Be aware that the need for specialized tank fabrication and expert installation can impact both the cost and schedule of using a PTFE sheet liner.

Ultimately, understanding these limitations allows you to select a lining system that ensures the long-term integrity and safety of your chemical processing operations.

Summary Table:

| Limitation | Key Impact | Consider Alternative When... |

|---|---|---|

| Poor Vacuum Resistance | Risk of delamination and liner failure under negative pressure. | Your process involves vacuum service. |

| Unsuitability for Complex Tanks | Difficult to install reliably on small tanks or those with baffles/nozzles. | Tank has intricate internal geometry. |

| Heavy Reliance on Installation & Tank Fabrication | Liner performance is capped by adhesive quality and substrate design. | You lack access to specialized fabricators and installers. |

Need a Lining Solution That Fits Your Specific Demands?

Understanding the limitations of PTFE sheet lining is the first step to selecting the right solution for your chemical process equipment. The right choice ensures long-term integrity, safety, and performance.

KINTEK specializes in manufacturing high-performance PTFE components, including custom liners, seals, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors with a focus on precision and durability. Whether your application requires a standard solution or a custom fabrication—from prototypes to high-volume orders—we have the expertise to guide you.

Let's discuss your project requirements and identify the optimal lining system for your needs.

Contact our experts today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are PTFE-coated gaskets and what are their limitations? Understanding the Risks of Surface Coatings

- What are the key advantages of PTFE-lined plug valves? Superior Sealing for Corrosive and Hazardous Media

- How does heat exposure affect PTFE seals? Mastering Thermal Expansion for Superior Sealing

- What are lined pipes and how do they work? Achieve Superior Chemical Resistance at a Lower Cost

- What are the key characteristics of PTFE rotary seals? Superior Performance for Extreme Conditions

- Why is PTFE used in medical applications? The Key to Biocompatible, Low-Friction Devices

- What temperature range can PTFE rotary shaft seals withstand? Operate from -200°C to +260°C

- What are the key features of PTFE lined valves? Maximize Safety and Cut Costs with Corrosion-Resistant Valves