In short, applying a PTFE coating is a precise, multi-stage industrial process that involves meticulous surface preparation, the application of both a primer and a topcoat, and a final high-temperature cure. These steps work in concert to chemically and mechanically bond the coating to a substrate, transforming a standard material into a high-performance surface.

The success of a PTFE coating is not determined by the final layer alone, but by the integrity of the entire system. From aggressive surface blasting to precise thermal curing, each step is critical for creating the non-stick, chemical-resistant, and durable finish required for demanding applications.

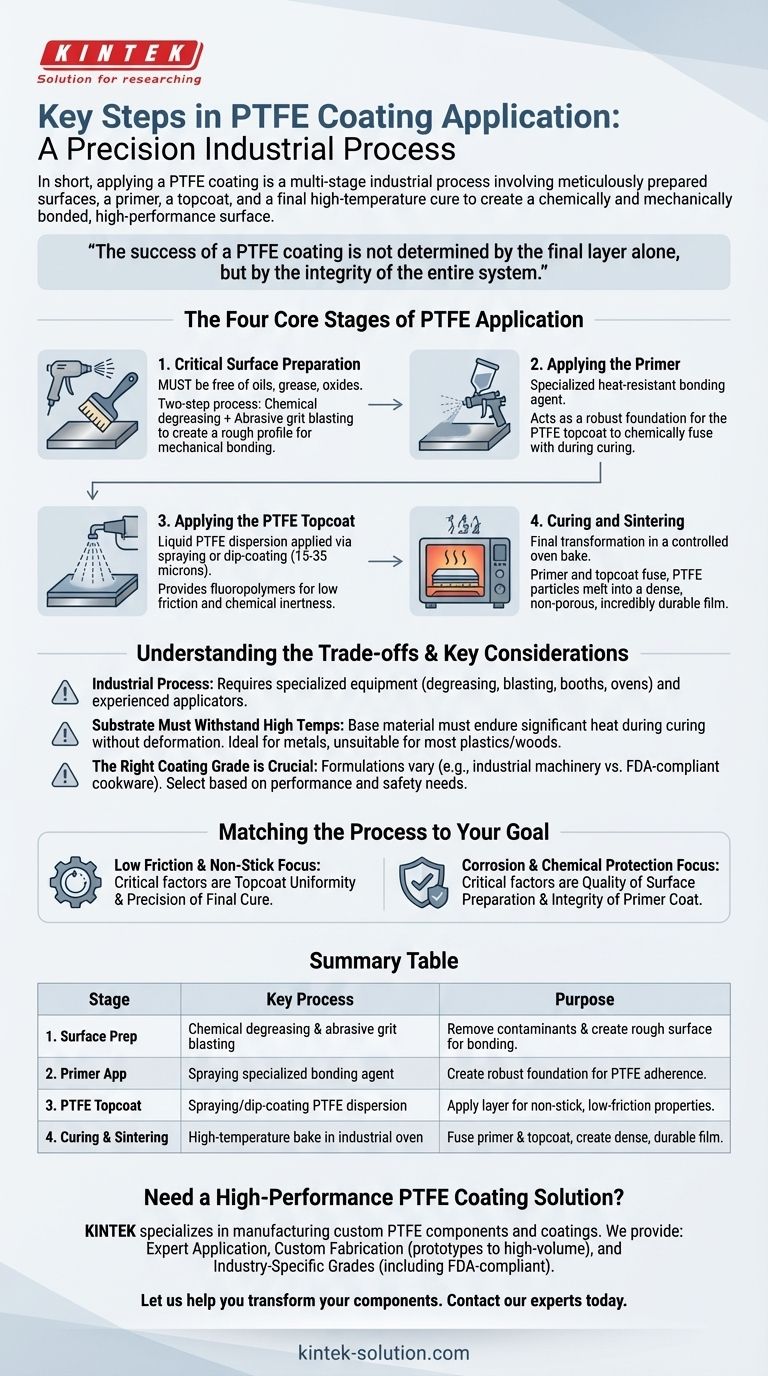

The Four Core Stages of PTFE Application

The application of PTFE is less like painting and more like a controlled chemical engineering process. Each stage builds upon the last to create a permanent, functional surface.

Stage 1: Critical Surface Preparation

The single most common point of failure for any industrial coating is improper surface preparation. The substrate must be completely free of oils, grease, and oxides for the coating to achieve a mechanical bond.

This is typically a two-step process involving chemical degreasing to remove organic contaminants, followed by abrasive grit blasting. Blasting creates a rough, textured surface profile that dramatically increases the surface area for the primer to grip onto.

Stage 2: Applying the Primer

After preparation, a specialized primer is applied. This is not the PTFE layer itself, but a heat-resistant bonding agent designed to adhere strongly to the metal substrate.

The primer acts as the essential intermediary, creating a robust foundation that the subsequent PTFE topcoat can chemically fuse with during the curing stage.

Stage 3: Applying the PTFE Topcoat

With the primer in place, the liquid PTFE dispersion is applied. This is typically done through conventional spraying or dip-coating to ensure an even, consistent layer.

This topcoat contains the unique fluoropolymers that give the final product its desired properties, such as low friction and chemical inertness. The thickness is carefully controlled, often falling within a range of 15 to 35 microns.

Stage 4: Curing and Sintering

This is the final and most critical transformation. The coated part is placed in a specialized industrial oven for a controlled bake, often called curing or sintering.

During this high-temperature cycle, the primer and topcoat fuse together and bond to the substrate. The PTFE particles melt and flow into a dense, non-porous, and incredibly durable film, locking in the high-performance characteristics.

Understanding the Trade-offs and Key Considerations

While highly effective, the PTFE coating process has specific requirements and limitations that must be understood to ensure a successful outcome.

It Is an Industrial Process

Applying a PTFE coating is not a simple workshop task. It requires specialized equipment, including degreasing tanks, grit-blasting cabinets, ventilated spray booths, and high-temperature curing ovens. This is a process managed by experienced applicators.

Substrate Must Withstand High Temperatures

The curing cycle involves significant heat. Therefore, the base material (the substrate) must be able to withstand these temperatures without deforming, warping, or losing its structural integrity. This makes it ideal for metals but unsuitable for most plastics or woods.

The Right Coating Grade is Crucial

Different applications demand different PTFE formulations. A non-stick coating for industrial machinery has different requirements than one used for food-grade cookware, which must be FDA-compliant. Selecting the correct grade is essential for both performance and safety.

Matching the Process to Your Goal

Understanding these steps allows you to specify the correct process and ensure the final product meets your performance requirements.

- If your primary focus is low friction and non-stick performance: The uniformity of the topcoat and the precision of the final cure are the most critical factors.

- If your primary focus is corrosion and chemical protection: The quality of the surface preparation and the integrity of the primer coat are paramount to creating an impermeable barrier.

Ultimately, viewing PTFE application as a complete system—not just a single layer—is the key to unlocking its remarkable material properties for your project.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Surface Preparation | Chemical degreasing & abrasive grit blasting | Remove contaminants and create a rough surface for mechanical bonding. |

| 2. Primer Application | Spraying a specialized bonding agent | Create a robust foundation for the PTFE topcoat to adhere to. |

| 3. PTFE Topcoat Application | Spraying or dip-coating a PTFE dispersion (15-35 microns) | Apply the layer that provides non-stick, low-friction properties. |

| 4. Curing & Sintering | High-temperature bake in an industrial oven | Fuse the primer and topcoat, creating a dense, durable, non-porous film. |

Need a High-Performance PTFE Coating Solution?

Achieving a flawless, durable PTFE coating requires precision and expertise at every stage. KINTEK specializes in manufacturing custom PTFE components and coatings for the semiconductor, medical, laboratory, and industrial sectors. Our process ensures superior chemical resistance, non-stick performance, and long-term durability.

We provide:

- Expert Application: Meticulous surface preparation and controlled curing for optimal bonding.

- Custom Fabrication: From prototypes to high-volume orders, tailored to your specific requirements.

- Industry-Specific Grades: Including FDA-compliant formulations for food and medical applications.

Let us help you transform your components with a high-performance PTFE coating. Contact our experts today for a consultation to discuss your project needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the features of PTFE with a Proprietary Organic Fill? Protect Soft Metals with Low-Friction Performance

- How do PTFE gaskets contribute to electrical insulation? Ensuring Reliability in Harsh Environments

- How does PTFE's molecular structure contribute to its non-stick properties? The Science Behind Its Slick Surface

- What are the primary applications of PTFE O-rings? Essential Sealing Solutions for Harsh Environments

- What temperature range can expanded PTFE gaskets withstand? From Cryogenic -200°C to High-Temp 260°C

- What are PTFE rods and how are they manufactured? A Guide to Their Properties and Production

- What factors should engineers consider when selecting PTFE gaskets? Ensure a Perfect Seal for Your Application

- What are the main benefits of PTFE envelope gaskets? Achieve Superior Chemical Resistance and Sealing Integrity