The key properties that make Teflon (PTFE) suitable for medical applications are its profound chemical inertness, an extremely low coefficient of friction (lubricity), and exceptional thermal stability. This unique combination ensures it does not react with bodily tissues, allows medical devices to move smoothly with minimal friction, and can withstand rigorous sterilization processes without degrading.

Teflon's value in medicine is not just about its famous non-stick quality. Its true advantage lies in its profound stability—it remains unchanged and safe when exposed to the aggressive chemical environment of the human body and the extreme temperatures of sterilization.

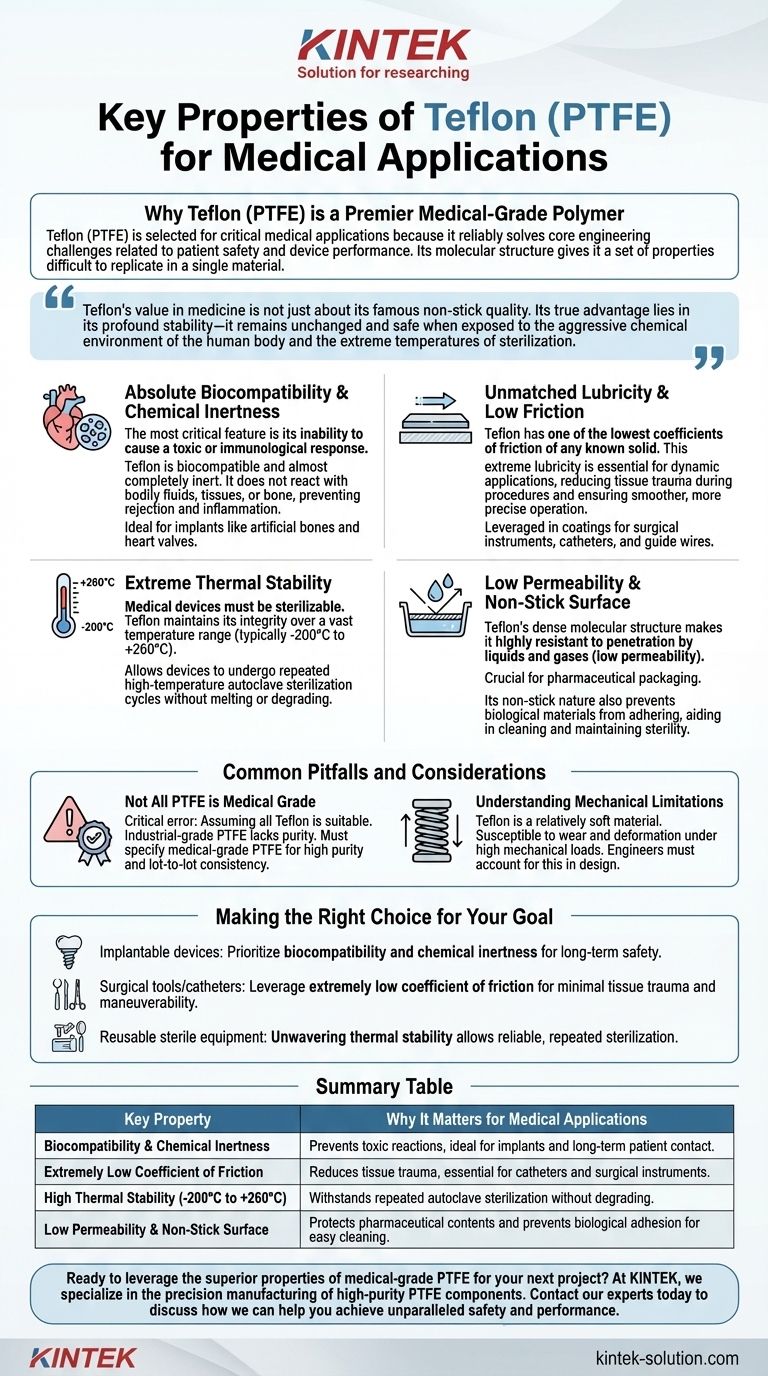

Why Teflon (PTFE) is a Premier Medical-Grade Polymer

Polytetrafluoroethylene (PTFE), commercially known as Teflon, is selected for critical medical applications because it reliably solves core engineering challenges related to patient safety and device performance. Its molecular structure gives it a set of properties that are difficult to replicate in a single material.

Absolute Biocompatibility and Chemical Inertness

The most critical feature of any implantable material is its inability to cause a toxic or immunological response. Teflon is biocompatible and almost completely inert.

It does not react with bodily fluids, tissues, or bone. This prevents rejection and inflammation, making it a trusted material for implants like artificial bones and heart valves.

Unmatched Lubricity and Low Friction

Teflon has one of the lowest coefficients of friction of any known solid. This extreme lubricity is essential for dynamic applications where surfaces slide against each other or against sensitive tissue.

This property is leveraged in coatings for surgical instruments, catheters, and guide wires, reducing tissue trauma during procedures and ensuring smoother, more precise operation.

Extreme Thermal Stability

Medical devices must be sterilizable, a process that often involves extreme heat. Teflon maintains its integrity over a vast temperature range, typically from -200°C to +260°C.

This resistance to heat allows devices coated with or made from Teflon to undergo repeated high-temperature autoclave sterilization cycles without melting, degrading, or losing their critical properties.

Low Permeability and Non-Stick Surface

Teflon's dense molecular structure makes it highly resistant to penetration by liquids and gases, a property known as low permeability.

This is crucial for pharmaceutical packaging and sterile containers, ensuring the contents are protected from contamination. Its non-stick nature also prevents biological materials from adhering to device surfaces, which aids in cleaning and maintaining sterility.

Common Pitfalls and Considerations

While Teflon's properties are highly advantageous, professionals must be aware of key considerations to ensure successful implementation and avoid common pitfalls.

Not All PTFE is Medical Grade

A critical error is assuming all Teflon is suitable for medical use. Industrial-grade PTFE does not have the same purity or manufacturing controls.

For medical applications, you must specify medical-grade PTFE, which guarantees high purity and lot-to-lot consistency. This ensures that every batch meets the strict safety and performance standards required for patient contact.

Understanding Mechanical Limitations

Teflon is a relatively soft material. While its low friction is an asset, it can be susceptible to wear and deformation under high mechanical loads or abrasive conditions.

Engineers must account for these mechanical properties during the design phase, ensuring the material is used in a way that leverages its strengths without exposing its weaknesses.

Making the Right Choice for Your Goal

Selecting a material is about matching its inherent properties to the primary demand of the application. Your specific goal will determine which of Teflon's characteristics is most important.

- If your primary focus is implantable devices: Prioritize its proven biocompatibility and chemical inertness to ensure long-term patient safety.

- If your primary focus is surgical tools or catheters: Leverage its extremely low coefficient of friction to minimize tissue trauma and improve device maneuverability.

- If your primary focus is reusable sterile equipment: Its unwavering thermal stability is the critical property that allows for reliable, repeated sterilization.

Ultimately, understanding these core principles empowers you to select materials that guarantee both device efficacy and patient well-being.

Summary Table:

| Key Property | Why It Matters for Medical Applications |

|---|---|

| Biocompatibility & Chemical Inertness | Prevents toxic reactions, ideal for implants and long-term patient contact. |

| Extremely Low Coefficient of Friction | Reduces tissue trauma, essential for catheters and surgical instruments. |

| High Thermal Stability (-200°C to +260°C) | Withstands repeated autoclave sterilization without degrading. |

| Low Permeability & Non-Stick Surface | Protects pharmaceutical contents and prevents biological adhesion for easy cleaning. |

Ready to leverage the superior properties of medical-grade PTFE for your next project?

At KINTEK, we specialize in the precision manufacturing of high-purity PTFE components—from custom seals and liners to complex labware—specifically for the demanding semiconductor, medical, and laboratory industries. Our expertise ensures your devices benefit from Teflon's full potential, with custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss how we can help you achieve unparalleled safety and performance in your medical applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications