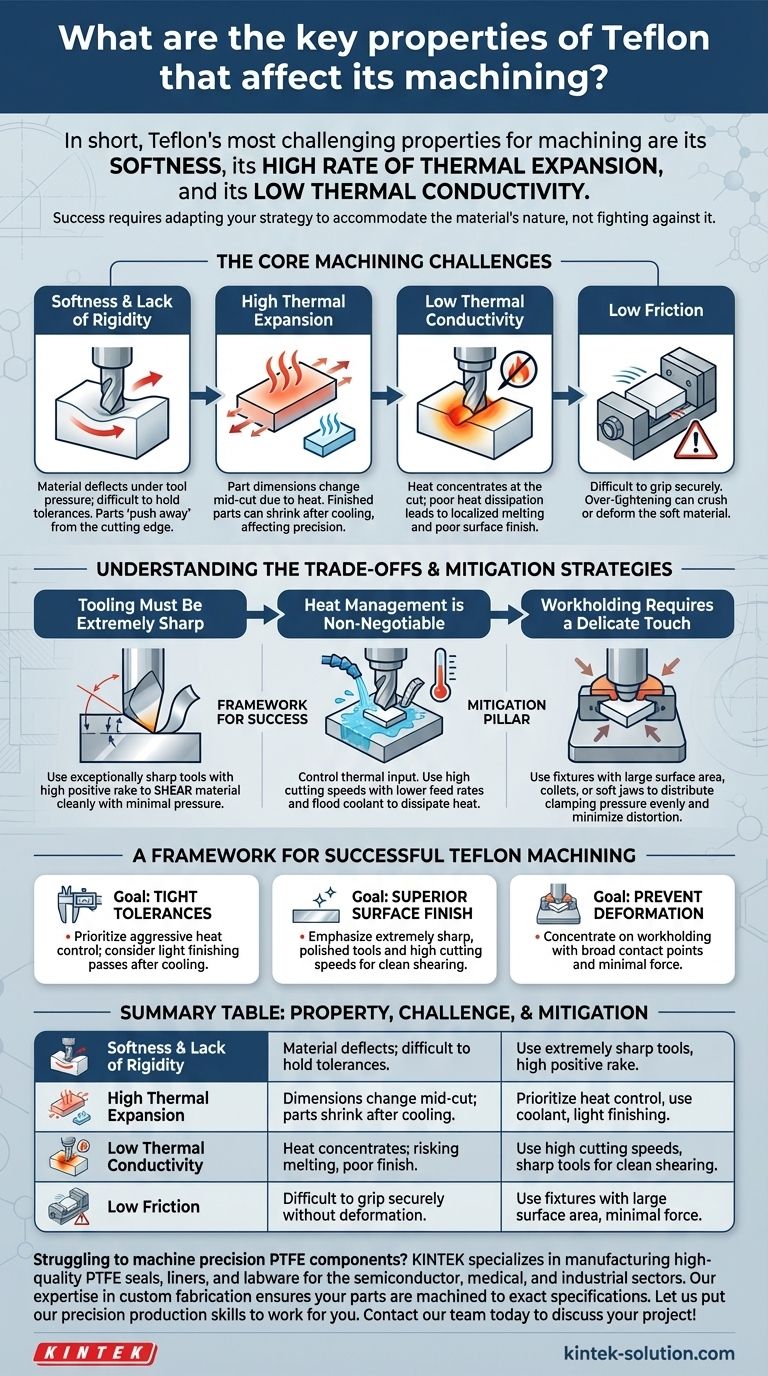

In short, Teflon's most challenging properties for machining are its softness, its high rate of thermal expansion, and its low thermal conductivity. While valued for its chemical inertness and low friction, these three characteristics demand a specific approach to tooling, speeds, and workholding to achieve precision.

The core challenge of machining Teflon (PTFE) is that its most desirable end-use properties—like low friction and stability—are intrinsically linked to the very physical traits that resist conventional machining techniques. Success requires adapting your strategy to accommodate the material's nature, not fighting against it.

The Core Machining Challenges Explained

To machine Teflon effectively, one must understand how its fundamental properties translate into real-world behavior under a cutting tool. The primary difficulties are not chemical but mechanical and thermal.

Softness and Lack of Rigidity

Teflon is a soft material with a Shore D hardness of around 57. It lacks the rigidity of metals or even many other engineering plastics.

This softness means the material can easily deflect or deform under tool pressure instead of shearing cleanly. This makes holding tight tolerances a significant challenge, as the part may simply "push away" from the cutting edge.

High Thermal Expansion

Teflon has a very high coefficient of thermal expansion. This means it expands significantly when it gets warm and contracts as it cools.

Friction from the machining process inevitably generates heat. As the workpiece heats up, it expands, causing the dimensions to change mid-cut. When the finished part cools, it can shrink to a size smaller than the intended dimension.

Low Thermal Conductivity

This property acts as a multiplier for the thermal expansion problem. Teflon is an excellent insulator and does not dissipate heat quickly.

The heat generated at the point of the cut remains concentrated in that area. This localized heating intensifies the thermal expansion issue and can even cause the material to exceed its low melting point (around 327°C), leading to a gummy texture and poor surface finish.

Low Friction: A Double-Edged Sword

While Teflon's famously low coefficient of friction (around 0.06 against steel) is a primary benefit in its final application, it creates a challenge during manufacturing.

The material's slipperiness makes it difficult to grip securely in chucks, vises, or fixtures. Over-tightening to compensate can easily crush or deform the soft material, leading to dimensional inaccuracies.

Understanding the Trade-offs and Mitigation

Successfully machining Teflon involves a strategy focused entirely on mitigating the effects of these properties. Ignoring them leads to scrapped parts and frustration.

Tooling Must Be Extremely Sharp

To counteract the material's softness, you must use exceptionally sharp cutting tools, often with a high positive rake and significant relief angles.

The goal is to shear the material cleanly with minimal pressure. A dull or improperly ground tool will plow through the material, causing it to tear, deform, and build up excessive heat.

Heat Management is Non-Negotiable

Because Teflon traps heat and expands, controlling the thermal input is critical. This is achieved through a combination of factors.

High cutting speeds with lower feed rates can help produce a smaller, more manageable chip that carries heat away. Using a flood coolant can also be effective at preventing heat buildup in the workpiece, though chip evacuation can sometimes be an issue.

Workholding Requires a Delicate Touch

Securing Teflon without deforming it is a key skill. The standard approach of simply tightening a vise or chuck is often counterproductive.

Use fixtures with a large surface area to distribute clamping pressure evenly. For lathes, using collets or soft jaws bored to the exact diameter of the workpiece provides a secure grip with minimal distortion.

A Framework for Successful Teflon Machining

Your approach should be dictated by the most critical outcome for your specific part. Adjust your strategy based on your primary goal.

- If your primary focus is achieving tight tolerances: Prioritize aggressive heat control using coolant and consider leaving a small amount of material for a very light finishing pass after the part has cooled and stabilized.

- If your primary focus is a superior surface finish: Emphasize using extremely sharp, polished tools with a high rake angle and high cutting speeds to ensure a clean shearing action.

- If your primary focus is preventing part deformation: Concentrate on your workholding strategy, using broad contact points and minimal clamping force to secure the workpiece without introducing stress.

Mastering Teflon machining comes from understanding and respecting its inherent properties rather than trying to force it to behave like metal.

Summary Table:

| Key Property | Machining Challenge | Mitigation Strategy |

|---|---|---|

| Softness & Lack of Rigidity | Material deflects under tool pressure; difficult to hold tolerances. | Use extremely sharp tools with high positive rake angles. |

| High Thermal Expansion | Part dimensions change mid-cut due to heat; parts shrink after cooling. | Prioritize heat control with coolant and light finishing passes. |

| Low Thermal Conductivity | Heat concentrates at the cut, risking melting and poor surface finish. | Use high cutting speeds and sharp tools to shear material cleanly. |

| Low Friction | Difficult to grip securely without deforming the soft material. | Use fixtures with large surface area and minimal clamping force. |

Struggling to machine precision PTFE components? KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts are machined to exact specifications, overcoming the unique challenges of Teflon. Let us put our precision production skills to work for you. Contact our team today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining