At its core, Polytetrafluoroethylene (PTFE) is renowned for an elite combination of properties. It offers extreme chemical resistance, stability across a vast temperature range, and one of the lowest coefficients of friction of any known solid, making it uniquely suited for demanding industrial applications where other materials fail.

The true value of PTFE lies not in any single attribute, but in its rare ability to deliver exceptional thermal stability, chemical inertness, and self-lubricating surfaces all at once. This combination makes it an indispensable problem-solver in aerospace, chemical processing, and electronics.

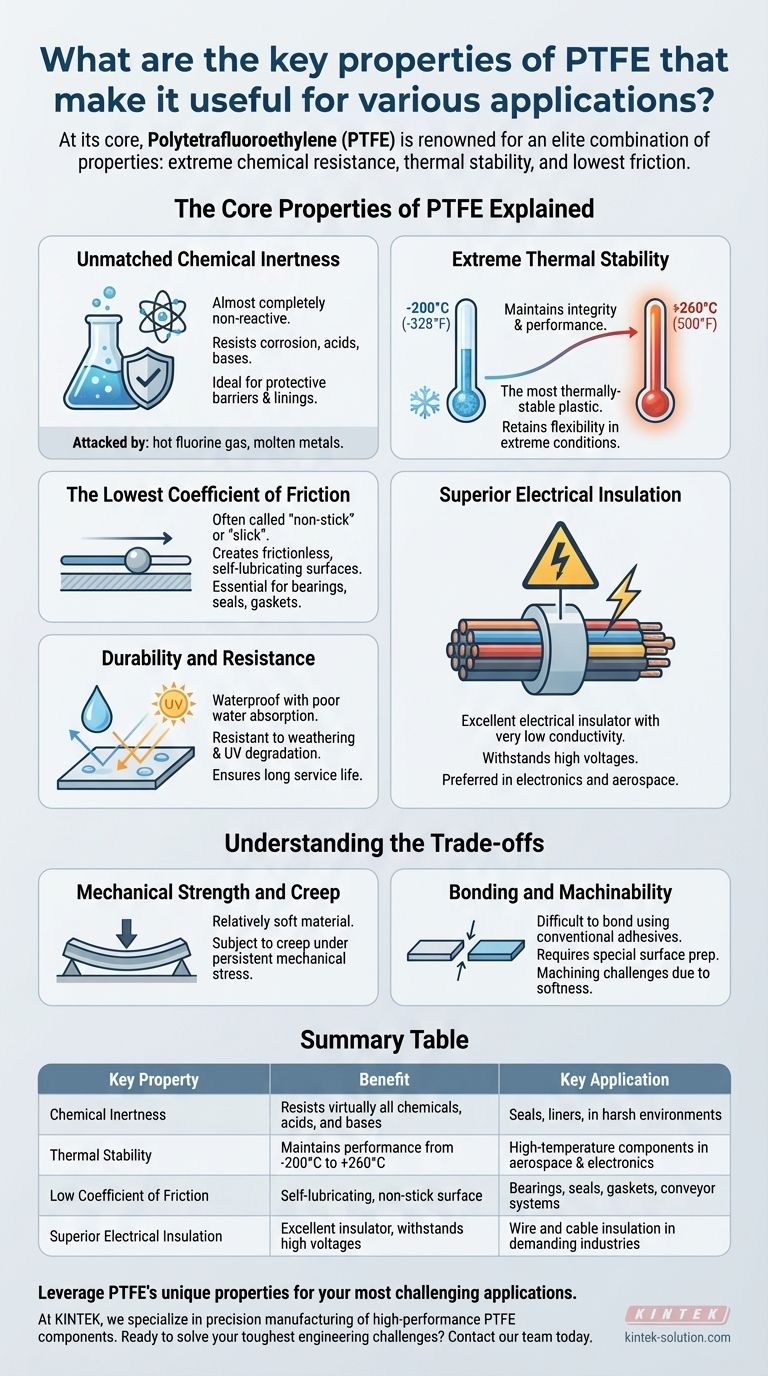

The Core Properties of PTFE Explained

To understand why PTFE is so versatile, we must break down its primary characteristics. Each property addresses a distinct set of engineering challenges.

Unmatched Chemical Inertness

PTFE is almost completely non-reactive. It exhibits extreme resistance to corrosion and is unaffected by most common chemicals, acids, and bases.

This property makes it an ideal material for creating protective barriers, linings, and components that will be exposed to harsh chemical environments. In fact, it can only be attacked by a few substances, like hot fluorine gas or certain molten metals.

Extreme Thermal Stability

PTFE maintains its structural integrity and performance across an exceptionally wide temperature range, from cryogenic lows of -200°C (-328°F) up to continuous service temperatures of +260°C (500°F).

This makes it the most thermally-stable plastic. It retains its key properties like strength and flexibility in conditions that would cause other polymers to become brittle or melt.

The Lowest Coefficient of Friction

Often described as "non-stick" or "slick," PTFE has one of the lowest friction values of any solid material. This allows it to create nearly frictionless, self-lubricating surfaces.

This anti-adhesive quality is critical for applications like bearings, seals, gaskets, and conveyor systems, where reducing wear and eliminating the need for external lubricants is essential.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with very low electrical conductivity. It can withstand high voltages, making it a reliable material for insulating wires and cables.

This property, combined with its high heat resistance, makes it a preferred choice for high-performance components in the electronics and aerospace industries.

Durability and Resistance

Beyond its primary attributes, PTFE is also waterproof due to its poor water absorption. It is highly resistant to weathering and degradation from UV light.

These features contribute to its long service life, even when used in exposed or harsh environmental conditions.

Understanding the Trade-offs

No material is perfect, and PTFE's unique strengths come with inherent limitations that are critical to understand for proper application.

Mechanical Strength and Creep

While durable, PTFE is a relatively soft material and does not possess the high tensile strength or rigidity of many engineering plastics.

It can be subject to creep, which is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. While it has good creep resistance for a fluoropolymer, it is a factor in high-load structural designs.

Bonding and Machinability

PTFE's non-stick, chemically inert surface makes it extremely difficult to bond to other materials using conventional adhesives. Special surface preparation techniques are required to achieve a reliable bond.

Its softness can also present challenges during machining, requiring specific tools and techniques to achieve tight tolerances without deforming the material.

Matching PTFE Properties to Your Application

Choosing a material requires aligning its strengths with your primary goal. The following guidelines will help you determine if PTFE is the optimal choice for your project.

- If your primary focus is harsh chemical environments: PTFE's near-total chemical inertness makes it the definitive choice for seals, linings, and fluid-handling components.

- If your primary focus is reducing friction and wear: Its self-lubricating, low-friction surface is ideal for high-performance bearings, slide plates, and non-stick coatings.

- If your primary focus is high-temperature or electrical insulation: Its thermal stability and exceptional dielectric properties are critical for demanding aerospace and electronics components.

By understanding its powerful combination of properties and limitations, you can leverage PTFE to solve engineering challenges that few other materials can address.

Summary Table:

| Key Property | Benefit | Key Application |

|---|---|---|

| Chemical Inertness | Resists virtually all chemicals, acids, and bases | Seals, liners, and components in harsh chemical environments |

| Thermal Stability | Maintains performance from -200°C to +260°C | High-temperature components in aerospace and electronics |

| Low Coefficient of Friction | Self-lubricating, non-stick surface | Bearings, seals, gaskets, and conveyor systems |

| Superior Electrical Insulation | Excellent insulator, withstands high voltages | Wire and cable insulation in demanding industries |

Leverage PTFE's unique properties for your most challenging applications.

At KINTEK, we specialize in precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components meet the highest standards of durability and performance.

Ready to solve your toughest engineering challenges? Contact our team today to discuss your custom PTFE fabrication needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the chemical properties of Teflon? The Science Behind Its Extreme Inertness

- Which industries commonly use PTFE due to its special properties? Solve Critical Engineering Challenges

- Why does PTFE have hydrophobic properties? The Science Behind Its Water-Repellent Power

- What industrial applications utilize expanded PTFE? Sealing, Filtration & Insulation Solutions

- Why is PTFE suitable for electrical applications? Discover Its Superior Insulating Properties

- What factors influence the price fluctuations of PTFE? A Guide to Navigating Raw Material Costs

- What are the limitations of PTFE? Understanding Creep, Abrasion, and Radiation Weaknesses

- Why is PTFE considered ideal for use in the food and beverage industry? Ensure Safety & Efficiency