Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by a unique combination of extreme properties. Its most notable characteristics are an incredibly low coefficient of friction, near-universal chemical inertness, excellent stability across a wide temperature range, and superior electrical insulation. These traits stem from the exceptionally strong bonds between its carbon and fluorine atoms.

The core takeaway is that PTFE is not an all-purpose plastic; it is a specialty material. Its world-class performance in friction, chemical resistance, and temperature stability makes it indispensable for harsh environments, but these same properties create practical limitations, such as difficulty in bonding, that must be carefully considered.

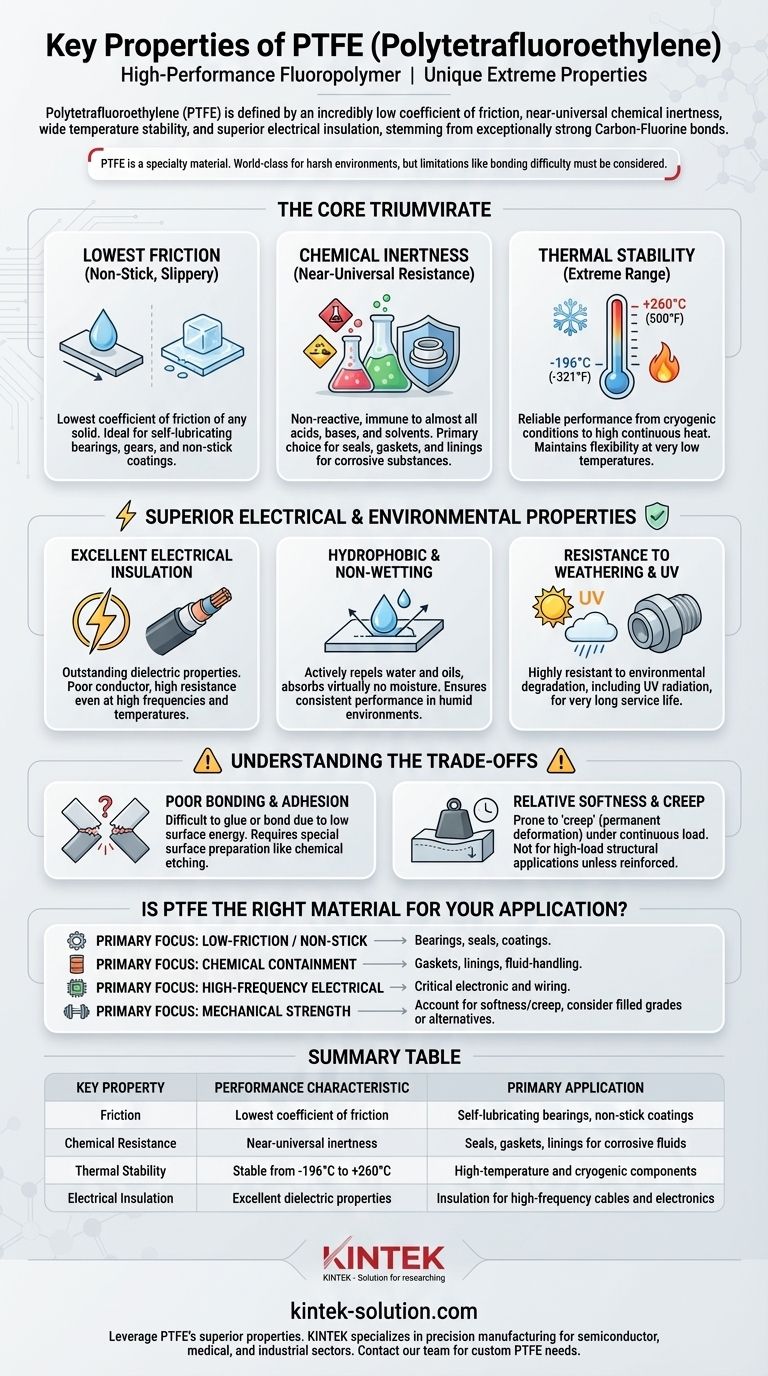

The Core Triumvirate: Friction, Chemistry, and Temperature

PTFE's reputation is built on three standout characteristics that are rarely found together in a single material.

The Lowest Friction of Any Solid

PTFE possesses the lowest known coefficient of friction of any solid material, often compared to wet ice on wet ice. This results in an exceptionally slippery, non-stick surface.

This property is not a coating but an inherent feature of the material, making it ideal for self-lubricating bearings, gears, and non-stick coatings where reducing resistance is critical.

Near-Universal Chemical Inertness

The carbon-fluorine bond in PTFE is one of the strongest in organic chemistry. This molecular stability makes the material non-reactive and virtually immune to attack from almost all industrial chemicals, acids, bases, and solvents.

Because it will not corrode or degrade, it is a primary choice for seals, gaskets, linings, and tubing that handle highly corrosive or pure substances.

Exceptional Thermal Stability

PTFE performs reliably across an extremely broad temperature range, from cryogenic conditions at -196°C (-321°F) up to continuous service at +260°C (500°F).

While its melting point is even higher (around 327°C / 621°F), it maintains its key properties like flexibility and toughness even at very low temperatures, where many other plastics would become brittle.

Superior Electrical and Environmental Properties

Beyond its primary traits, PTFE offers a set of secondary characteristics that make it highly valuable in specific technical applications.

Excellent Electrical Insulation

PTFE has outstanding dielectric properties, meaning it is a very poor conductor of electricity. It maintains high electrical resistance and dielectric strength even at high frequencies and temperatures.

This makes it a top-tier material for insulating high-frequency cables, wires, and critical electronic components where signal integrity and safety are paramount.

Hydrophobic and Non-Wetting

The material actively repels water and oils and absorbs virtually no moisture. This property, known as being hydrophobic, ensures its performance remains consistent even in humid environments.

This lack of water absorption contributes to its excellent electrical insulation and dimensional stability.

Resistance to Weathering and UV

PTFE is highly resistant to degradation from environmental factors, including UV radiation from sunlight. It does not become brittle or break down with long-term outdoor exposure, giving it a very long service life.

Understanding the Trade-offs

No material is perfect. The same properties that make PTFE unique also introduce specific design and manufacturing challenges.

Poor Bonding and Adhesion

PTFE's non-stick, low-friction surface makes it extremely difficult to glue or bond to other materials. Its low surface energy prevents adhesives from wetting the surface and forming a strong bond.

To overcome this, special surface preparation techniques like chemical etching are often required, adding complexity and cost to the manufacturing process.

Relative Softness and Creep

While tough, PTFE is a relatively soft material compared to other engineering plastics. Under a continuous, sustained load, it can be prone to "creep," a slow, permanent deformation over time.

This means it is generally not suitable for high-load structural applications unless it is reinforced with fillers like glass, carbon, or bronze.

Lower Mechanical Strength

Compared to structural polymers like PEEK or Nylon, PTFE has lower tensile strength and wear resistance. Its value lies in its unique combination of other properties, not its raw mechanical prowess.

Is PTFE the Right Material for Your Application?

Choosing the correct material requires aligning its properties with your primary engineering goal.

- If your primary focus is creating a low-friction or non-stick surface: PTFE's exceptionally low coefficient of friction makes it a best-in-class choice for bearings, seals, and coatings.

- If your primary focus is containing aggressive chemicals or solvents: Its near-universal chemical inertness makes it an excellent and reliable candidate for gaskets, linings, and fluid-handling components.

- If your primary focus is high-frequency electrical insulation: Its outstanding and stable dielectric properties are a key advantage for critical electronic and wiring applications.

- If your primary focus is mechanical strength and load-bearing: You must account for its relative softness and potential for creep, and you may need to specify a filled grade or investigate alternative high-strength polymers.

Ultimately, understanding both the profound strengths and the inherent limitations of PTFE is the key to leveraging it successfully in demanding applications.

Summary Table:

| Key Property | Performance Characteristic | Primary Application |

|---|---|---|

| Friction | Lowest coefficient of friction of any solid | Self-lubricating bearings, non-stick coatings |

| Chemical Resistance | Near-universal inertness to acids, bases, solvents | Seals, gaskets, linings for corrosive fluids |

| Thermal Stability | Stable from -196°C to +260°C | High-temperature and cryogenic components |

| Electrical Insulation | Excellent dielectric properties, even at high frequencies | Insulation for high-frequency cables and electronics |

Leverage PTFE's superior properties for your most demanding applications. KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components meet exact specifications for friction, chemical resistance, and thermal stability. Contact our team today to discuss your custom PTFE fabrication needs.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What are the primary applications of Teflon? Leverage Its Unique Properties for Your Industry

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the primary applications of PTFE? Unlocking High-Performance Solutions