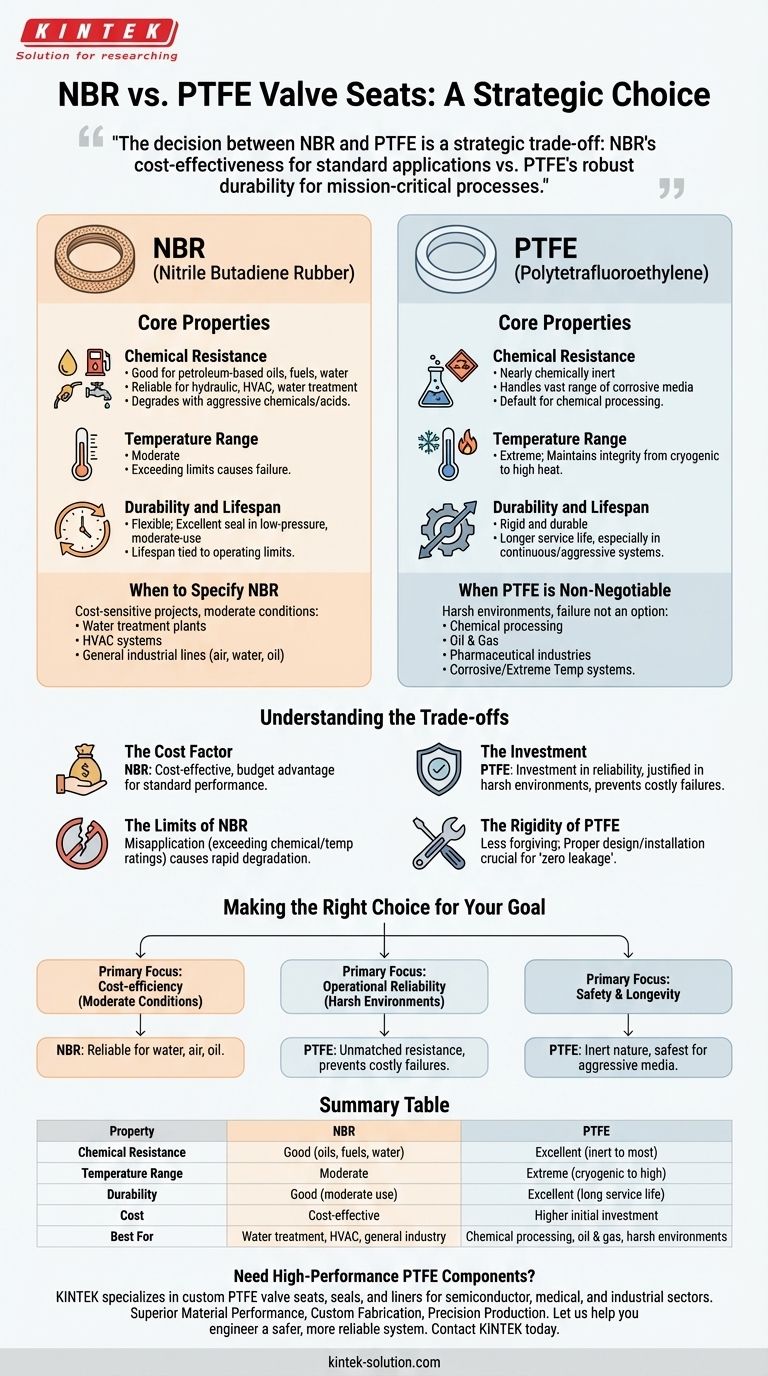

The primary difference between NBR and PTFE valve seats lies in their fundamental material properties, which dictate their performance in specific industrial environments. NBR is a flexible, cost-effective rubber ideal for general-purpose applications with moderate temperatures and chemicals like oils and water. In contrast, PTFE is a high-performance plastic engineered for harsh service, offering superior resistance to aggressive chemicals and extreme temperatures.

The decision between NBR and PTFE is a strategic trade-off. You are choosing between NBR's cost-effectiveness for standard applications and PTFE's robust durability for mission-critical or harsh industrial processes where reliability is paramount.

Core Properties: A Head-to-Head Comparison

To select the right material, it is essential to understand how their core attributes align with your operational demands.

Chemical Resistance

NBR (Nitrile Butadiene Rubber) offers good resistance to petroleum-based oils, fuels, and water. It is a reliable choice for many hydraulic, HVAC, and water treatment systems.

However, NBR will degrade when exposed to aggressive chemicals, solvents, or acids.

PTFE (Polytetrafluoroethylene) is nearly chemically inert. It can handle a vast range of corrosive media, making it the default choice for chemical processing and other demanding industries.

Temperature Range

NBR seats are suitable for a moderate temperature range. Exceeding its upper or lower limits will cause the material to become brittle or soft, leading to seal failure.

PTFE excels in extreme conditions, maintaining its integrity and sealing capability across a much wider temperature spectrum, from cryogenic lows to high-temperature highs.

Durability and Lifespan

NBR is flexible and provides an excellent seal in low-pressure, moderate-use applications. Its lifespan is directly tied to operating within its specified chemical and thermal limits.

PTFE is a more rigid and durable material. This translates to a longer service life, especially in systems with continuous operation or aggressive media, ensuring reliable, long-term sealing performance.

Understanding the Trade-offs

While performance is key, practical considerations like cost and operational limitations are equally important.

The Cost Factor

NBR is a significantly more cost-effective material. For large-scale projects or applications where its performance is sufficient, NBR presents a clear budget advantage.

Choosing PTFE is an investment in reliability. Its higher upfront cost is justified in environments where a valve failure would result in costly downtime, safety hazards, or environmental damage.

The Limits of NBR

The most common failure scenario is misapplication. Using an NBR seat in a system with chemicals or temperatures beyond its rating is a critical error that will lead to rapid degradation and leaks.

The Rigidity of PTFE

While its durability is a strength, PTFE is a less forgiving material than NBR. This makes proper valve design and installation crucial to achieve its characteristic "zero leakage" sealing performance.

Matching the Material to the Application

The choice ultimately comes down to the specific demands of the service environment.

When to Specify NBR

NBR is the optimal choice for cost-sensitive projects with predictable, moderate conditions. This includes applications like water treatment plants, HVAC systems, and general industrial lines handling air, water, or petroleum-based oils.

When PTFE is Non-Negotiable

PTFE is essential for harsh environments where failure is not an option. It is the standard for the chemical processing, oil and gas, and pharmaceutical industries, or any system handling corrosive chemicals or operating at extreme temperatures.

Making the Right Choice for Your Goal

Select your valve seat material based on a clear understanding of your system's primary requirement.

- If your primary focus is cost-efficiency for moderate conditions: NBR is the clear choice, offering reliable performance for water, air, and oil applications without over-engineering the solution.

- If your primary focus is operational reliability in harsh environments: PTFE is the necessary investment, providing unmatched chemical and thermal resistance that prevents costly failures and ensures long-term durability.

- If your primary focus is safety and longevity: PTFE's robust and inert nature makes it the safest choice for handling aggressive media, protecting both your system and your personnel.

Choosing the correct seat material is fundamental to ensuring the safety, efficiency, and longevity of your fluid control system.

Summary Table:

| Property | NBR (Nitrile Butadiene Rubber) | PTFE (Polytetrafluoroethylene) |

|---|---|---|

| Chemical Resistance | Good for oils, fuels, water | Excellent; nearly inert to most chemicals |

| Temperature Range | Moderate | Extreme (cryogenic to high heat) |

| Durability | Good for moderate use | Excellent; long service life |

| Cost | Cost-effective | Higher initial investment |

| Best For | Water treatment, HVAC, general industry | Chemical processing, oil & gas, harsh environments |

Need High-Performance PTFE Components for Demanding Applications?

Selecting the right material is critical for valve performance and system safety. KINTEK specializes in manufacturing precision PTFE components—including custom valve seats, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We ensure reliability in the most challenging environments through:

- Superior Material Performance: Our PTFE components offer exceptional chemical resistance and thermal stability.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your exact specifications.

- Precision Production: Quality and consistency are built into every part we make.

Let us help you engineer a safer, more reliable system. Contact KINTEK today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability