At its core, the primary benefit of using PTFE gaskets in ball valves is their unique combination of near-universal chemical inertness, a wide operational temperature range, and an extremely low coefficient of friction. This trifecta of properties ensures the valve operates smoothly and reliably, even when handling aggressive chemicals or operating in extreme thermal conditions.

The decision to use a PTFE gasket in a ball valve is a decision for operational reliability. While other materials may excel in a single area, PTFE provides an unparalleled balance of chemical resistance, thermal stability, and self-lubricating properties essential for the rotational movement and sealing integrity of a ball valve.

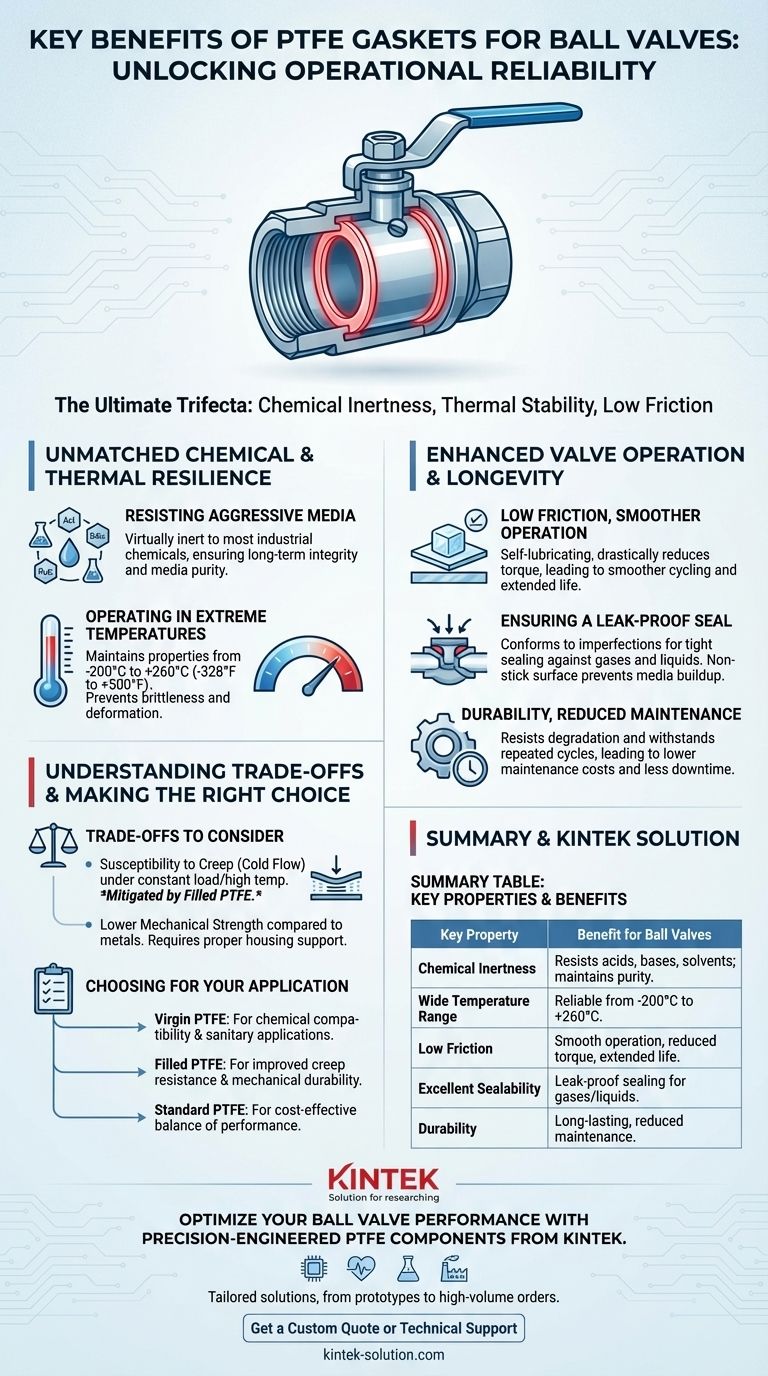

The Unmatched Chemical and Thermal Resilience of PTFE

A gasket's fundamental purpose is to maintain a seal under operational stress. For ball valves used in industrial processes, this stress is often chemical and thermal.

Resisting Aggressive Media

PTFE is virtually inert to almost all industrial chemicals, including potent acids, bases, and solvents. This chemical resistance prevents the gasket from degrading, swelling, or corroding over time.

This ensures the purity of the media flowing through the valve is maintained, which is critical in industries like pharmaceuticals and food processing. It also guarantees the long-term integrity of the seal itself.

Operating in Extreme Temperatures

PTFE gaskets maintain their physical properties and sealing capability across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This stability prevents the material from becoming brittle at cryogenic temperatures or deforming under high heat, ensuring a consistent and reliable seal regardless of the process conditions.

How PTFE Enhances Valve Operation and Longevity

Beyond simple resilience, PTFE possesses mechanical properties that are uniquely suited to the function of a ball valve, which relies on a rotational component.

The Critical Role of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property is a significant advantage in a ball valve.

It drastically reduces the torque required to open and close the valve, leading to smoother operation and allowing for smaller, less expensive actuators. This also minimizes wear on both the ball and the gasket (or seat), extending the valve's operational life.

Ensuring a Leak-Proof Seal

Despite its rigidity, PTFE is soft enough to conform to minor imperfections on sealing surfaces when compressed. This conformability is key to creating a tight, leak-proof seal against both gases and liquids.

Its non-stick surface also prevents process media from adhering to the gasket, ensuring a clean seal and easy disassembly for maintenance without damaging the gasket.

Durability for Reduced Maintenance

The combination of chemical, thermal, and mechanical stability gives PTFE gaskets exceptional durability. They resist degradation from harsh conditions and withstand repeated compression cycles without losing their sealing ability.

This longevity translates directly to lower maintenance costs, less frequent downtime, and greater overall system reliability.

Understanding the Trade-offs

While PTFE is a superior material for many applications, it's important to understand its limitations to make a fully informed decision.

Susceptibility to Creep

Standard, or "virgin," PTFE can be susceptible to creep, also known as cold flow. This is a tendency for the material to slowly deform over time when under a constant load, particularly at higher temperatures.

In high-pressure applications, this can eventually lead to a loss of sealing pressure. This is often mitigated by using filled PTFE, where materials like glass, carbon, or bronze are added to enhance mechanical strength and creep resistance.

Lower Mechanical Strength

Compared to metals or harder polymers, PTFE is a relatively soft material. This makes it unsuitable for applications requiring extreme rigidity or resistance to high abrasion.

The design of the valve and its housing must properly support the gasket to prevent it from being extruded from the joint under high pressure.

Making the Right Choice for Your Application

Selecting the correct gasket material is about matching the properties to the specific demands of your system.

- If your primary focus is chemical compatibility and purity: Virgin PTFE is the definitive choice for handling aggressive media or for use in sanitary applications like food, beverage, and pharmaceuticals.

- If your primary focus is high-pressure or high-cycle operation: Look to filled PTFE compounds that offer improved creep resistance and mechanical durability for a longer service life.

- If your primary focus is general-purpose reliability: Standard PTFE provides an outstanding and cost-effective balance of performance for a vast range of industrial ball valve applications.

Ultimately, choosing PTFE is an investment in the long-term, trouble-free performance of your critical valve systems.

Summary Table:

| Key Property | Benefit for Ball Valves |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; maintains media purity. |

| Wide Temperature Range | Operates reliably from -200°C to +260°C (-328°F to +500°F). |

| Low Friction | Self-lubricating for smooth operation, reduced torque, and extended valve life. |

| Excellent Sealability | Conforms to surface imperfections for leak-proof sealing against gases and liquids. |

| Durability | Long-lasting performance with reduced maintenance and downtime. |

Optimize your ball valve performance with precision-engineered PTFE components from KINTEK.

Whether you need standard or custom PTFE gaskets, seals, liners, or labware, KINTEK delivers solutions tailored for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact fit and performance your application demands.

Contact us today to discuss your specific requirements and experience the KINTEK difference in quality and reliability.

Get a Custom Quote or Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why are PTFE control valves important in chemical industries? Ensure Safety and Reliability in Harsh Environments

- What are the different types of PTFE rotary shaft seals and their applications? Choose the Right Seal for Your Machinery

- What role do Teflon-encapsulated O-Rings play in the oil and gas and chemical processing industries? A Critical Sealing Solution

- What are PTFE envelope gaskets used for? Protect Delicate Flanges & Seal Aggressive Chemicals

- What role do Teflon rods play in the electrical and electronics industry? Ensure Superior Insulation and Reliability

- What factors should be considered when choosing a PTFE expansion joint? Ensure System Safety and Longevity

- What are the common types of fillers used in PTFE compounds? Enhance Performance for Demanding Applications

- How should slide bearings be designed when using white PTFE or Teflon? Master the Two-Part System for Low Friction