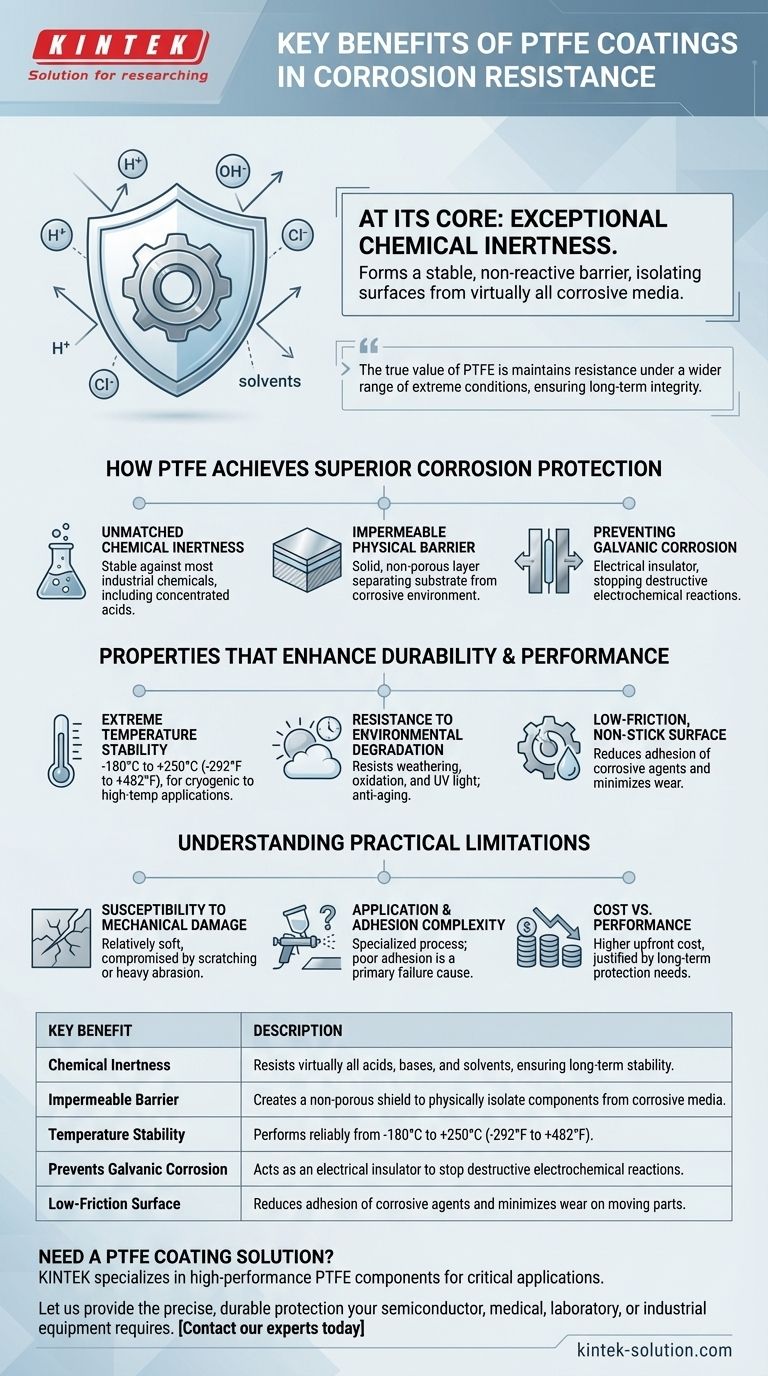

At its core, the primary benefit of a Polytetrafluoroethylene (PTFE) coating for corrosion resistance is its exceptional chemical inertness. This property allows it to form a stable, non-reactive barrier that physically isolates a component's surface from virtually all corrosive media, including strong acids, bases, solvents, and saltwater. This barrier effectively prevents the chemical and electrochemical reactions that cause degradation.

The true value of PTFE is not just that it resists corrosion, but that it maintains this resistance under a wider range of extreme conditions—chemical, thermal, and environmental—than most other protective coatings, ensuring long-term component integrity and performance.

How PTFE Achieves Superior Corrosion Protection

To understand why PTFE is so effective, we must look at its fundamental material properties. Its protective qualities are not just a surface-level feature but are inherent to its molecular structure.

Unmatched Chemical Inertness

PTFE is one of the most chemically non-reactive substances known. It remains stable and does not degrade when exposed to the vast majority of industrial chemicals, including concentrated sulfuric and nitric acid.

This inertness means the coating itself won't break down, ensuring the protective shield remains intact even during continuous exposure to highly aggressive substances.

An Impermeable Physical Barrier

The coating creates a solid, non-porous layer that physically separates the underlying metal or substrate from its environment. This shield is the first and most critical line of defense against corrosive agents.

In industries like oil and gas, this barrier is crucial for protecting critical equipment from constant contact with saltwater and other corrosive fluids.

Preventing Galvanic Corrosion

Because PTFE is an excellent electrical insulator, it can prevent galvanic corrosion. This type of corrosion occurs when two different metals are in electrical contact in the presence of an electrolyte.

By insulating the components, the PTFE coating breaks the electrical circuit necessary for this destructive electrochemical reaction to occur.

Properties That Enhance Durability and Performance

PTFE's effectiveness is amplified by a collection of other properties that allow it to function in demanding real-world applications where simple corrosion isn't the only challenge.

Extreme Temperature Stability

PTFE coatings maintain their integrity and protective properties across an exceptionally wide temperature range, typically from -180°C to +250°C (-292°F to +482°F).

This allows it to protect components in cryogenic applications as well as high-temperature processing environments without becoming brittle or degrading.

Resistance to Environmental Degradation

Unlike many other materials, PTFE is highly resistant to weathering, oxidation, and UV light. This anti-aging characteristic ensures it will not crack or break down over time, even with prolonged outdoor exposure.

This makes it an ideal choice for equipment that must operate reliably in harsh external conditions for years.

Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This "slipperiness" provides two benefits. First, it reduces the ability of corrosive or fouling agents to adhere to the surface.

Second, this inherent lubrication reduces wear and tear on moving parts, which lowers energy consumption and helps maintain the integrity of the protective coating itself.

Understanding the Practical Limitations

While its properties are impressive, PTFE is not a universal solution. An objective assessment requires acknowledging its trade-offs.

Susceptibility to Mechanical Damage

PTFE is a relatively soft material. The coating can be compromised by scratching, heavy abrasion, or direct impact. Any breach in the coating can expose the underlying substrate, creating a potential point for corrosion to begin.

Application and Adhesion Complexity

Properly applying a PTFE coating is a specialized process that requires meticulous surface preparation, precise application techniques, and controlled curing. Poor adhesion is a primary cause of coating failure, making the quality of the application just as important as the material itself.

Cost vs. Performance

High-performance PTFE coatings typically have a higher upfront cost compared to conventional paints or epoxy coatings. The investment must be justified by the need for long-term protection in environments where lesser coatings would quickly fail.

Making the Right Choice for Your Application

Selecting a coating requires matching its strengths to the specific demands of your environment.

- If your primary focus is extreme chemical exposure: PTFE is an unmatched choice for equipment in chemical processing, pharmaceutical, and laboratory settings due to its near-total chemical inertness.

- If your primary focus is marine or outdoor durability: PTFE's combined resistance to saltwater, UV light, and weathering makes it ideal for protecting components in offshore, oil and gas, and coastal applications.

- If your primary focus is performance across temperature extremes: PTFE is the correct solution for aerospace, industrial baking, or cryogenic systems where coatings must remain stable and protective.

Ultimately, choosing a PTFE coating is an investment in unparalleled reliability and extended component life under the most challenging conditions.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents, ensuring long-term stability. |

| Impermeable Barrier | Creates a non-porous shield to physically isolate components from corrosive media. |

| Temperature Stability | Performs reliably from -180°C to +250°C (-292°F to +482°F). |

| Prevents Galvanic Corrosion | Acts as an electrical insulator to stop destructive electrochemical reactions. |

| Low-Friction Surface | Reduces adhesion of corrosive agents and minimizes wear on moving parts. |

Need a PTFE Coating Solution for Your Demanding Application?

KINTEK specializes in manufacturing high-performance PTFE components—including custom-coated seals, liners, and labware—for industries where corrosion resistance is critical. Our expertise ensures your components are protected against the harshest chemicals, extreme temperatures, and environmental challenges, extending their service life and reliability.

Let us provide the precise, durable protection your semiconductor, medical, laboratory, or industrial equipment requires.

Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications