In the chemical industry, Teflon gland fillers are prized for their exceptional chemical inertness, high-temperature resilience, and low-friction properties. These characteristics make them a superior choice for creating durable, reliable seals in equipment that handles aggressive or high-purity substances, ensuring both safety and operational efficiency.

The core reason Teflon excels as a gland filler is its unique combination of properties. It simultaneously resists chemical attack that would destroy other materials while providing a low-friction, self-lubricating seal that minimizes wear on moving parts and prevents costly leaks.

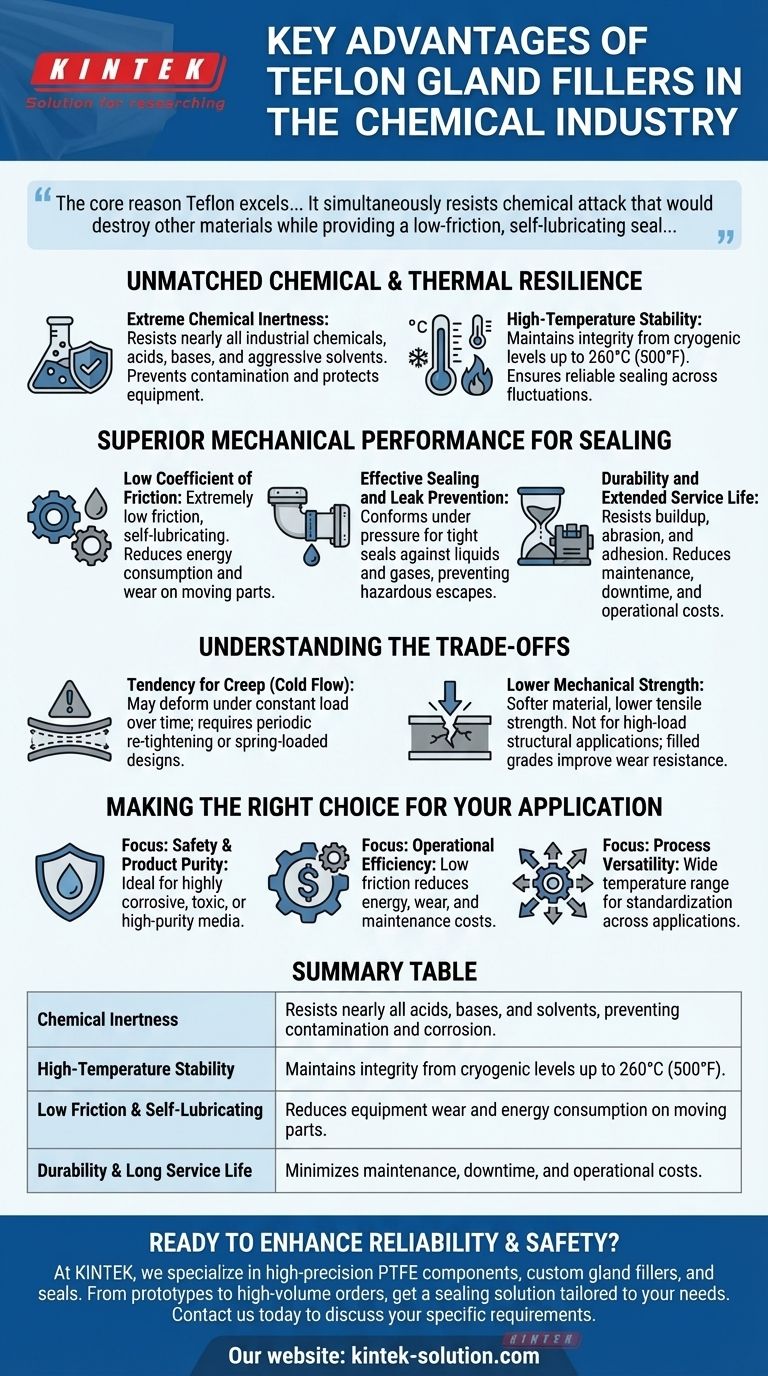

Unmatched Chemical & Thermal Resilience

The primary function of a seal in the chemical industry is to contain substances without degrading. Teflon's molecular structure makes it uniquely suited for this demanding role.

Extreme Chemical Inertness

Teflon (PTFE) is famously resistant to nearly all industrial chemicals, including strong acids, bases, and aggressive organic solvents.

This inertness is critical for preventing contamination of the process media and protecting equipment, like pump shafts and valve stems, from corrosion. It is a default choice for handling substances like sulfuric acid or hydrofluoric acid.

High-Temperature Stability

Chemical processes often involve a wide range of operating temperatures. Teflon maintains its integrity and sealing capability across a broad thermal spectrum, from cryogenic levels up to approximately 260°C (500°F).

This stability ensures a reliable seal even during temperature fluctuations, preventing failures that could occur with less resilient materials.

Superior Mechanical Performance for Sealing

Beyond resisting its environment, a gland filler must perform its mechanical sealing duty effectively and for a long time.

Low Coefficient of Friction

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This is a significant advantage for seals on rotating shafts (pumps) or reciprocating stems (valves).

This self-lubricating property dramatically reduces the energy required to operate the equipment and minimizes wear on moving components, extending the life of both the seal and the machine itself.

Effective Sealing and Leak Prevention

Teflon gland packing conforms well under pressure to create a tight, effective seal against both liquids and gases.

This prevents the escape of hazardous, valuable, or environmentally sensitive materials, which is fundamental to safe and compliant plant operation. For example, it ensures tight seals in gas handling systems to prevent dangerous leaks.

Durability and Extended Service Life

The combination of chemical resistance, wear resistance, and anti-adhesion properties means Teflon gland fillers have a very long service life.

They resist buildup from sticky media and withstand the abrasion of continuous operation. This durability leads directly to reduced maintenance requirements, less equipment downtime, and lower operational costs.

Understanding the Trade-offs

While Teflon is a premier material, no engineering choice is without trade-offs. Understanding its limitations is key to successful application.

Tendency for Creep (Cold Flow)

Teflon can slowly deform or "creep" over time when placed under a constant compressive load, especially at elevated temperatures.

This means that gland packings may require periodic re-tightening to maintain the proper sealing pressure. In some designs, this is managed by incorporating other materials or using spring-loaded glands.

Lower Mechanical Strength

Compared to metals or even some high-performance plastics, Teflon is a relatively soft material with lower tensile strength and abrasion resistance against hard particulates.

It is an exceptional sealing material but is not intended for high-load structural applications. In environments with abrasive slurries, filled-PTFE grades (e.g., carbon or glass-filled) are often used to improve wear resistance.

Making the Right Choice for Your Application

Selecting Teflon is often a strategic decision based on the most critical operational need.

- If your primary focus is safety and product purity: Teflon's unmatched chemical inertness makes it the ideal choice for handling highly corrosive, toxic, or high-purity media without risk of contamination or seal degradation.

- If your primary focus is operational efficiency: The low-friction and self-lubricating properties reduce energy consumption and equipment wear, leading to lower maintenance costs and less downtime.

- If your primary focus is process versatility: Teflon's wide operating temperature range allows it to be standardized across many different applications within a facility, simplifying inventory and maintenance procedures.

Ultimately, choosing Teflon gland fillers is an investment in reliability, safety, and long-term operational performance for your most demanding chemical applications.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Inertness | Resists nearly all acids, bases, and solvents, preventing contamination and corrosion. |

| High-Temperature Stability | Maintains integrity from cryogenic levels up to 260°C (500°F). |

| Low Friction & Self-Lubricating | Reduces equipment wear and energy consumption on moving parts. |

| Durability & Long Service Life | Minimizes maintenance, downtime, and operational costs. |

Ready to enhance the reliability and safety of your chemical processes?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom gland fillers and seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution perfectly tailored to your application's demands for chemical resistance, temperature stability, and longevity.

Contact us today to discuss your specific requirements and let our experts help you achieve superior sealing performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications