In short, PTFE expansion joints are fundamentally superior to rubber in applications involving aggressive chemicals, extreme temperatures, and high pressures. Their unique material properties provide a level of durability and chemical inertness that traditional rubber simply cannot match in demanding industrial environments.

The core decision between PTFE and rubber expansion joints is an environmental one. PTFE is the necessary choice for harsh, corrosive, or high-temperature systems where rubber would quickly degrade, while rubber remains a practical solution for more standard, less demanding applications.

Why PTFE Excels in Demanding Environments

The advantages of Polytetrafluoroethylene (PTFE) are rooted in its unique molecular structure. This structure gives it properties that make it exceptionally resilient in conditions that would cause other materials, like rubber, to fail.

Unmatched Chemical Inertness

PTFE offers nearly universal corrosion resistance. It is inert to almost all industrial chemicals and solvents, making it the definitive choice for pipelines carrying aggressive media.

Traditional rubber joints, by contrast, have specific chemical vulnerabilities and must be carefully matched to the service, creating a higher risk of material degradation and failure if specified incorrectly.

Superior High-Temperature Performance

PTFE operates effectively across an exceptionally wide temperature range, typically from -200°C to 260°C. This stability ensures reliability in systems with significant thermal fluctuations.

Rubber compounds have a much narrower operating window and can become brittle at low temperatures or lose structural integrity at high temperatures.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property reduces resistance to flow and minimizes energy consumption within the piping system.

This low-friction surface also resists contamination and buildup, a critical advantage in maintaining system efficiency and purity.

Enhanced Durability and Lifespan

The material's excellent wear resistance and immunity to aging from UV or weather exposure give PTFE joints a significantly longer service life.

This extended lifespan, which can be 10,000 to 50,000 hours in some applications, leads to reduced maintenance cycles and lower long-term ownership costs.

Critical Design and Operational Advantages

Beyond its core material strengths, PTFE provides practical benefits that improve the overall integrity and design of a piping system.

Excellent Flexibility and Movement Absorption

Like all expansion joints, PTFE models are designed to be flexible connectors that absorb thermal growth, system vibrations, and pipe misalignments. This protects the entire pipeline from stress-induced damage.

Compact, Space-Saving Design

PTFE expansion joints can often be designed with a shorter face-to-face length compared to their rubber counterparts. This makes them ideal for installation in tight or confined spaces.

Hygienic Properties

The non-porous and non-contaminating surface of PTFE makes it an ideal material for hygienic applications. This is critical in industries like food processing, pharmaceuticals, and biotechnology where purity is paramount.

Understanding the Trade-offs

While PTFE offers superior performance in extreme conditions, it is essential to recognize that traditional rubber joints are not obsolete. The choice is a matter of selecting the right tool for the job.

The Role of Application Severity

For standard applications, such as water lines, HVAC systems, or pipelines with neutral media and moderate temperatures, a rubber expansion joint is often a perfectly suitable and more cost-effective solution.

Cost Considerations

PTFE is a premium material, and its initial purchase price is typically higher than that of a standard rubber joint. The decision must weigh this upfront cost against the long-term benefits of reduced maintenance and superior durability in demanding environments.

Making the Right Choice for Your System

Selecting the correct expansion joint requires a clear understanding of your system's operational demands.

- If your primary focus is handling aggressive chemicals or extreme temperatures: PTFE is the only reliable choice to ensure system safety and longevity.

- If your primary focus is a general-purpose system with moderate pressure and temperature: A traditional rubber joint is often the most practical and economical solution.

- If your primary focus is maintaining product purity or low-friction flow: PTFE's hygienic and self-lubricating properties provide a clear advantage.

Ultimately, matching the material to the environment is the key to a reliable and efficient piping system.

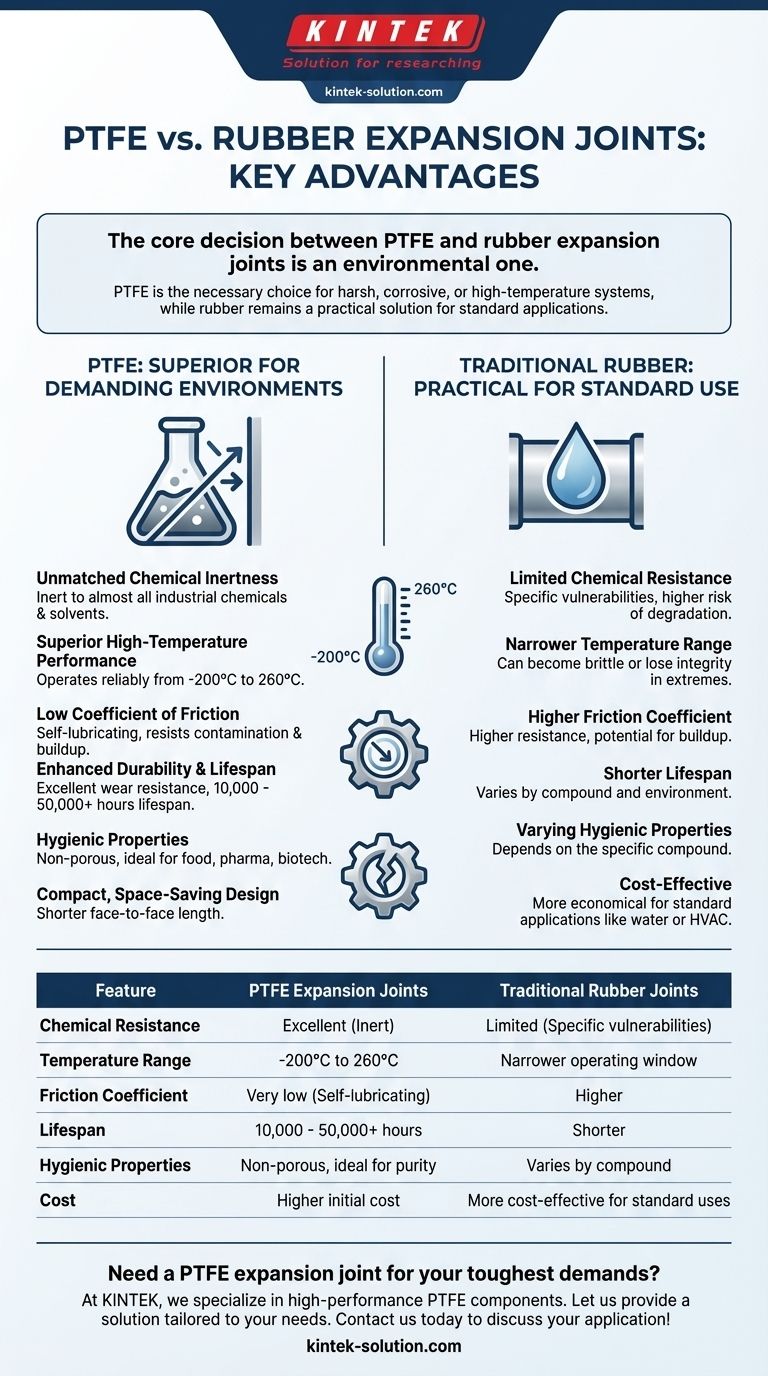

Summary Table:

| Feature | PTFE Expansion Joints | Traditional Rubber Joints |

|---|---|---|

| Chemical Resistance | Excellent (Inert to most chemicals) | Limited (Specific vulnerabilities) |

| Temperature Range | -200°C to 260°C | Narrower operating window |

| Friction Coefficient | Very low (Self-lubricating) | Higher |

| Lifespan | 10,000 to 50,000+ hours | Shorter |

| Hygienic Properties | Non-porous, ideal for purity | Varies by compound |

| Cost | Higher initial cost | More cost-effective for standard uses |

Need a PTFE expansion joint that can handle your system's toughest demands?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom expansion joints, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment operates reliably with aggressive chemicals, extreme temperatures, and high pressures—reducing downtime and long-term costs.

Let us provide a solution tailored to your needs, from prototypes to high-volume orders. Contact us today to discuss your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments