In essence, modified PTFE is an enhanced version of standard Polytetrafluoroethylene that retains its exceptional chemical resistance and low friction while dramatically improving its mechanical properties. It is created through a chemical co-polymerization process and often includes inorganic fillers, which combine to significantly reduce creep (deformation under load), lower porosity, and increase overall strength.

The core problem with standard PTFE is its mechanical weakness; it deforms easily under pressure. Modified PTFE solves this fundamental issue, transforming a chemically brilliant but structurally soft material into a robust engineering polymer suitable for demanding sealing and structural applications.

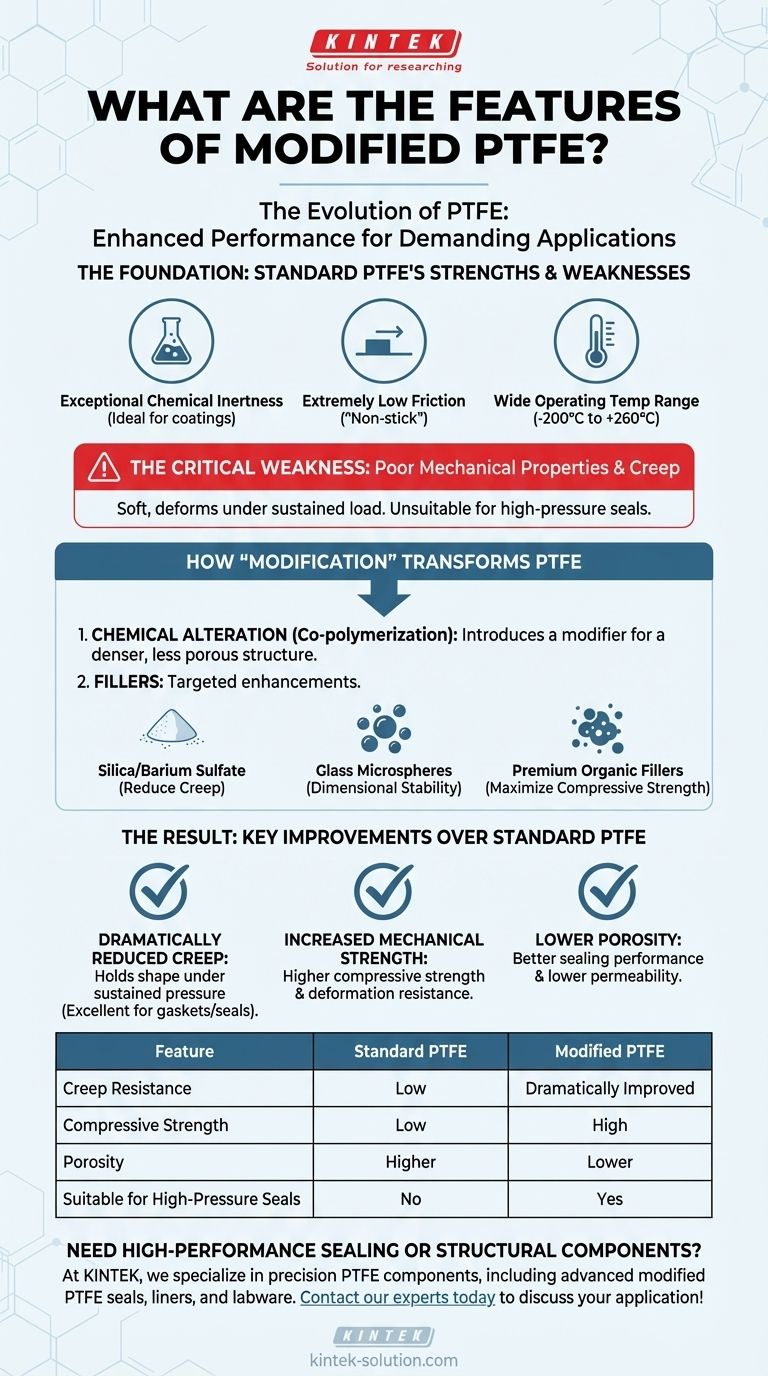

The Foundation: Standard PTFE's Strengths and Weaknesses

To understand modified PTFE, you must first appreciate the characteristics of the material it's built upon. Standard PTFE is renowned for a unique combination of properties.

Exceptional Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals. This makes it an ideal material for coating pipes, vessels, and equipment used in aggressive chemical processing environments.

Extremely Low Friction

With one of the lowest coefficients of friction of any solid, PTFE is the original "non-stick" material. This property is invaluable for bearings, seals, and other components where smooth movement is critical.

Wide Operating Temperature Range

Standard PTFE performs reliably across an incredibly broad temperature spectrum, typically from –200°C to +260°C (–328°F to +500°F), maintaining its properties in cryogenic and high-heat conditions.

The Critical Weakness: Poor Mechanical Properties

The primary drawback of standard PTFE is its softness and tendency to creep, or slowly deform, when subjected to a sustained load. This makes it unsuitable for high-pressure gaskets or structural parts that must maintain their exact shape over time.

How "Modification" Transforms PTFE

Modified PTFE addresses the mechanical shortcomings of the standard version through two key enhancements: chemical alteration and the addition of fillers.

The Core Chemical Change: Co-polymerization

The "modification" begins at the molecular level. A small quantity (typically less than 1%) of a perfluorinated modifier is introduced during polymerization. This subtle change to the polymer chain results in a denser, less porous material structure that is also capable of being self-fused.

The Role of Fillers: Enhancing Specific Properties

After the chemical modification, various inorganic or organic fillers are often blended into the material. Each filler is chosen to target a specific performance improvement.

- Silica and Barium Sulfate are commonly used to significantly reduce creep.

- Glass Microspheres can improve dimensional stability and stiffness.

- Premium Organic Fillers can be used to maximize compressive strength.

The Result: Key Improvements Over Standard PTFE

This two-pronged approach gives modified PTFE its superior performance characteristics.

Dramatically Reduced Creep

This is the most significant advantage. Modified PTFE holds its shape under sustained pressure, making it an excellent material for gaskets and seals in critical flange applications where leakage is not an option.

Increased Mechanical Strength

The combination of a modified polymer structure and reinforcing fillers provides higher compressive strength and greater resistance to deformation, allowing its use in more demanding mechanical roles.

Lower Porosity

The denser molecular structure created during co-polymerization reduces voids in the material. This leads to better sealing performance and lower permeability to gases and liquids.

Understanding the Trade-offs

While highly effective, choosing a modified PTFE requires acknowledging its specific nature and variations.

Not a Single Material

"Modified PTFE" is a category, not a single product. The specific properties—from color (white, blue, fawn) to compressive strength—depend entirely on the type of filler used.

Cost and Complexity

The advanced polymerization process and the addition of fillers make modified PTFE a more specialized and typically more expensive material than standard, or "virgin," PTFE.

Filler-Specific Limitations

While the PTFE base remains highly inert, certain aggressive chemicals may react with a specific filler. Therefore, material selection must account for both the base polymer and the filler type when evaluating chemical compatibility.

Selecting the Right PTFE for Your Application

Your final choice should be dictated by the specific demands of your engineering goal.

- If your primary focus is pure chemical inertness in a low-load application: Standard (virgin) PTFE is often the most cost-effective and suitable choice.

- If your application involves gaskets or seals under sustained pressure: Modified PTFE is essential to prevent creep and ensure a reliable, long-lasting seal.

- If you need high compressive strength or wear resistance for dynamic parts: A filled modified PTFE (e.g., with organic or glass fillers) provides the necessary structural integrity.

Ultimately, choosing modified PTFE is a strategic decision to overcome the inherent mechanical limitations of standard PTFE, enabling its use in more demanding engineering roles.

Summary Table:

| Feature | Standard PTFE | Modified PTFE |

|---|---|---|

| Creep Resistance | Low | Dramatically Improved |

| Compressive Strength | Low | High |

| Porosity | Higher | Lower |

| Suitable for High-Pressure Seals | No | Yes |

Need a high-performance sealing or structural component that can withstand sustained pressure and aggressive chemicals?

At KINTEK, we specialize in manufacturing precision PTFE components, including advanced modified PTFE seals, liners, and labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to your exact requirements in the semiconductor, medical, laboratory, and industrial sectors.

Let us help you overcome the limitations of standard PTFE. Contact our experts today to discuss your application and receive a customized quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems