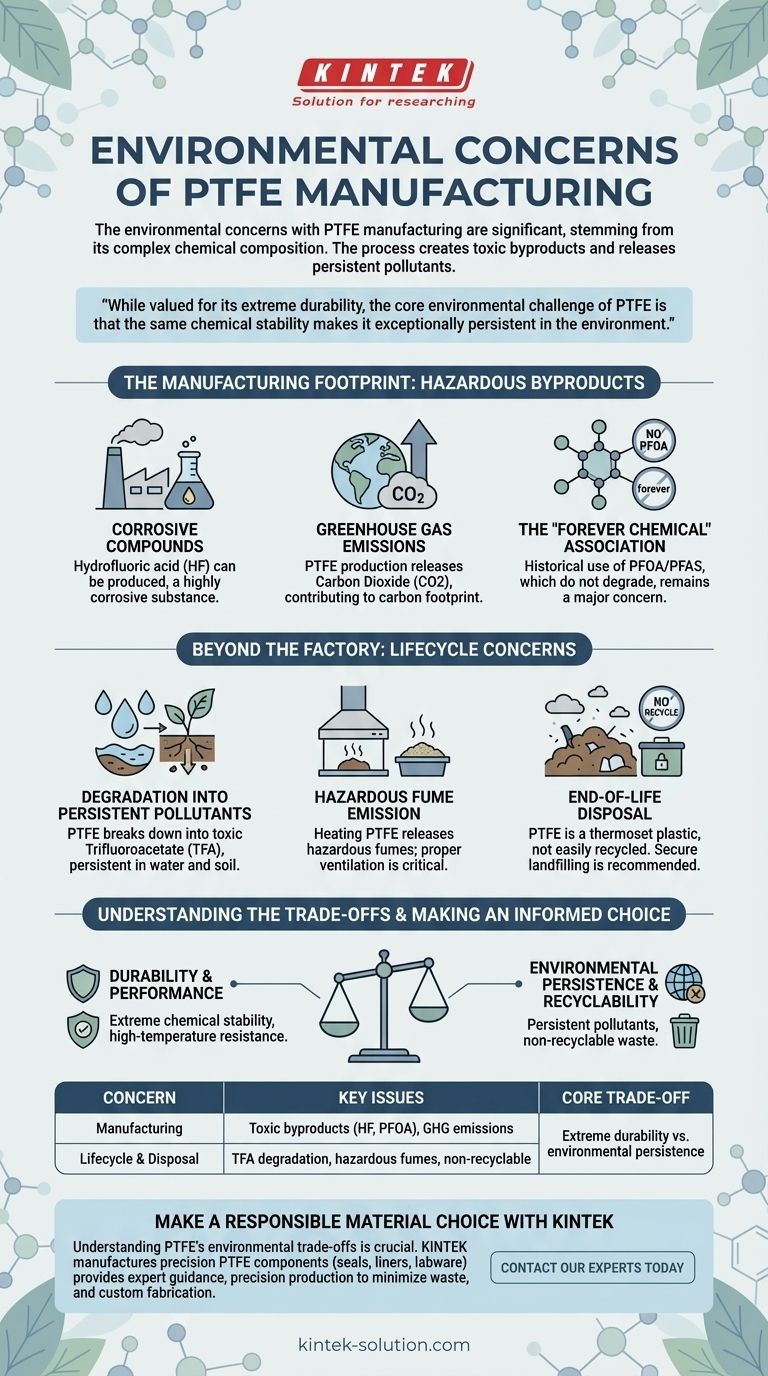

The environmental concerns with PTFE manufacturing are significant, stemming directly from its complex chemical composition. The process creates toxic byproducts, including hydrofluoric acid, and its end-of-life degradation releases persistent pollutants like trifluoroacetate (TFA) into the soil and water.

While valued for its extreme durability and chemical inertness, the core environmental challenge of Polytetrafluoroethylene (PTFE) is that the same chemical stability that makes it useful also makes it exceptionally persistent in the environment.

The Manufacturing Footprint: Hazardous Byproducts

The initial synthesis of PTFE from raw chemical inputs is an energy-intensive process that carries inherent environmental risks. The primary concerns are not just greenhouse gases but also highly toxic outputs.

Creation of Corrosive Compounds

During manufacturing, hydrofluoric acid can be produced as a byproduct. This is a highly corrosive and toxic substance that requires stringent controls to prevent its release and protect worker safety and the surrounding environment.

Greenhouse Gas Emissions

Like many chemical manufacturing processes, PTFE production releases carbon dioxide (CO2). While not unique to PTFE, it contributes to the overall carbon footprint of any project utilizing the material.

The "Forever Chemical" Association

Historically, the manufacturing of PTFE required the use of processing aids like PFOA (perfluorooctanoic acid). PFOA is part of a larger class of PFAS (per- and polyfluoroalkyl substances), often called "forever chemicals" because they do not naturally break down and can accumulate in the environment and living organisms. While many manufacturers have phased out PFOA, the legacy of its use remains a major environmental concern.

Beyond the Factory: Lifecycle Concerns

The environmental impact of PTFE does not end once the material is produced. Its effects are felt throughout its use, processing, and disposal stages.

Degradation into Persistent Pollutants

Over time or through specific processes, PTFE can break down into other substances. One of these is trifluoroacetate (TFA), a compound that is toxic to plants and is highly persistent in water and soil, creating long-term contamination risks.

Hazardous Fume Emission

When PTFE is heated to high temperatures, such as during aggressive machining or if used beyond its temperature rating, it can release hazardous fumes. Proper ventilation and handling are critical not only for operator safety but also to prevent the release of these pollutants into the atmosphere.

End-of-Life Disposal

PTFE is a thermoset plastic and is not easily recycled. Its chemical inertness means it does not biodegrade in landfills. The recommended disposal method is secure landfilling to contain the material and prevent it from breaking down into smaller, more mobile particles in the environment.

Understanding the Trade-offs

Choosing PTFE involves a direct trade-off between its unparalleled performance in certain applications and its undeniable environmental persistence.

Durability vs. Persistence

The very properties that make PTFE valuable—its extreme chemical stability and resistance to degradation—are the root of its environmental problem. A material designed to not break down in harsh industrial environments will also not break down in a natural one.

Performance vs. Recyclability

Unlike common thermoplastics like PET or Polypropylene, PTFE cannot be simply melted and remolded. This lack of a viable, large-scale recycling pathway means that nearly all PTFE produced eventually becomes waste.

Making an Informed Material Choice

Evaluating PTFE requires balancing its unique performance capabilities against its complete environmental lifecycle cost.

- If your primary focus is mission-critical performance (e.g., extreme chemical resistance or high-temperature stability): Acknowledge the environmental impact and ensure strict handling, machining, and end-of-life disposal protocols are in place.

- If your primary focus is environmental sustainability: Aggressively seek alternative materials, especially for applications where the extreme properties of PTFE are over-engineered for the task.

Understanding the full lifecycle, from production byproducts to end-of-life persistence, is the foundation of responsible material selection.

Summary Table:

| Environmental Concern | Key Issues |

|---|---|

| Manufacturing | Toxic byproducts (e.g., hydrofluoric acid), greenhouse gas emissions, historical use of PFOA/PFAS |

| Lifecycle & Disposal | Degradation into persistent pollutants (TFA), hazardous fume emission if overheated, non-recyclable (secure landfilling required) |

| Core Trade-off | Extreme durability and chemical inertness vs. environmental persistence and lack of recyclability |

Make a Responsible Material Choice with KINTEK

Understanding the environmental trade-offs of PTFE is crucial for your application. At KINTEK, we manufacture precision PTFE components (seals, liners, labware) for the semiconductor, medical, laboratory, and industrial sectors. We help you navigate these challenges by:

- Providing expert guidance on material selection to ensure PTFE is the right choice for your performance needs.

- Emphasizing precision production to minimize waste and maximize component lifespan.

- Offering custom fabrication from prototypes to high-volume orders, ensuring you get exactly what you need without excess.

Let's discuss your project requirements and find the most effective, responsible solution. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application