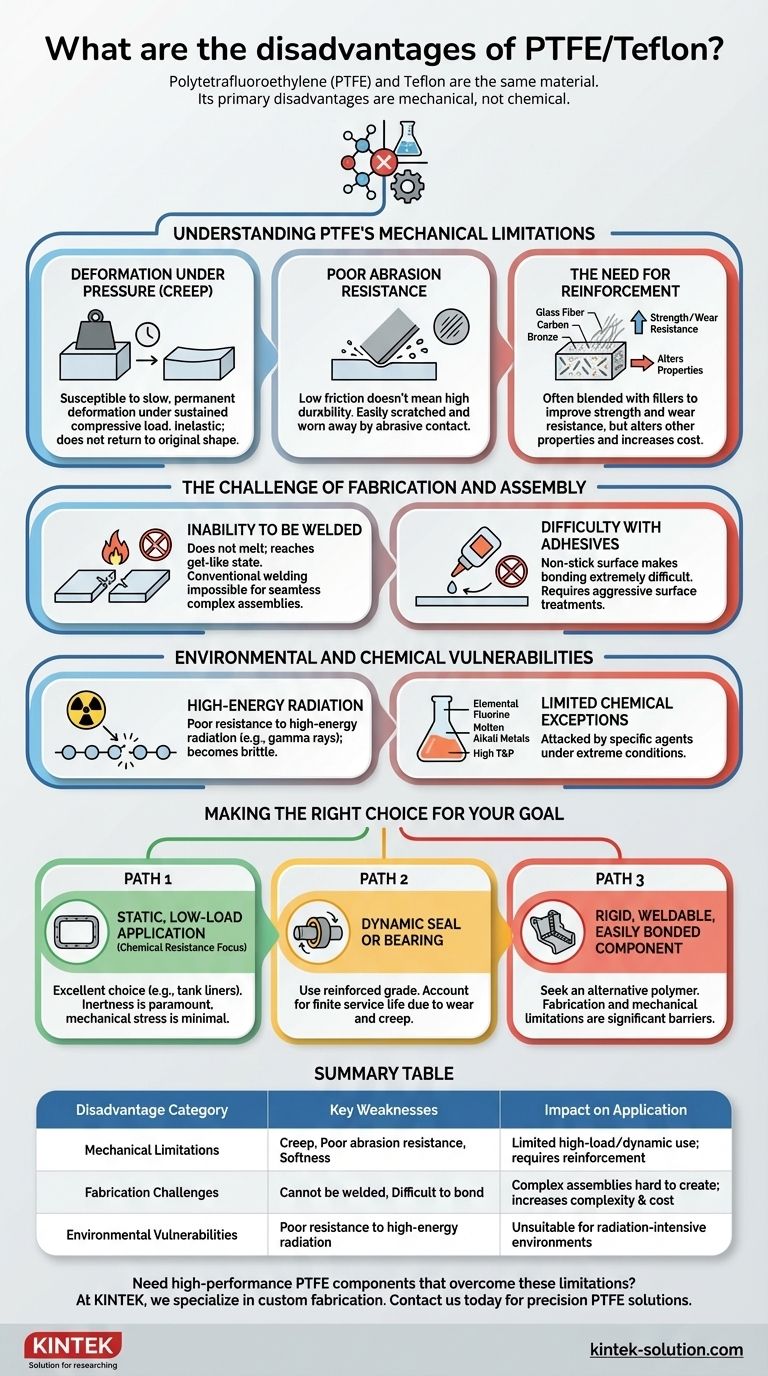

To be clear, Polytetrafluoroethylene (PTFE) and Teflon are the same material. PTFE is the polymer's chemical name, while Teflon is the well-known brand name. Its primary disadvantages are not chemical but mechanical; it is soft, deforms under pressure, and has poor resistance to abrasion. These physical limitations, combined with challenges in fabrication, define its practical constraints.

While PTFE is famous for its extreme chemical inertness and low friction, its effectiveness in any application is ultimately governed by its significant mechanical weaknesses. Understanding these trade-offs is the key to avoiding component failure.

Understanding PTFE's Mechanical Limitations

The most common points of failure for PTFE are physical, not chemical. Its molecular structure, which provides incredible non-stick properties, also results in a mechanically soft material.

Deformation Under Pressure (Creep)

PTFE is not a rigid material. When subjected to a sustained compressive load, it is susceptible to creep, meaning it will slowly and permanently deform over time.

It is also inelastic and does not return to its original shape after a force is removed. This makes it unsuitable for applications that require a component to maintain a precise shape under load.

Poor Abrasion Resistance

The material's low friction does not equate to high durability. PTFE is easily scratched and worn away by abrasive contact.

This lack of abrasion resistance can significantly shorten the service life of components in dynamic applications where parts slide against each other.

The Need for Reinforcement

To counteract its softness and tendency to creep, pure PTFE is often blended with other materials.

Adding fillers like glass fiber, carbon, or bronze can dramatically improve its strength, wear resistance, and dimensional stability, but this also alters its other properties and increases cost.

The Challenge of Fabrication and Assembly

Working with PTFE presents unique challenges that limit how it can be used to create complex parts or integrated systems.

Inability to be Welded

Unlike many thermoplastics, PTFE does not melt into a liquid state when heated. Instead, it reaches a gel-like state before decomposing at higher temperatures.

This characteristic makes conventional welding impossible, preventing the creation of seamless, complex assemblies from smaller pieces.

Difficulty with Adhesives

The very non-stick surface that makes PTFE so valuable also makes it extremely difficult to glue or cement.

Bonding PTFE requires aggressive chemical etching or other surface treatments to create a bondable surface, adding complexity and cost to the assembly process.

Environmental and Chemical Vulnerabilities

While known for its near-total chemical resistance, PTFE does have specific weaknesses that can lead to failure in certain environments.

High-Energy Radiation

PTFE has poor resistance to high-energy radiation, such as gamma rays. This radiation can break down the polymer's molecular chains, causing the material to become brittle and lose its structural integrity.

Limited Chemical Exceptions

In very specific, aggressive conditions, PTFE can be attacked. This is limited to agents like elemental fluorine and certain molten alkali metals or exotic fluorinating agents (like chlorine trifluoride) at high temperatures and pressures.

Making the Right Choice for Your Goal

You must evaluate PTFE based on the primary demand of your application. Its unique profile makes it a perfect fit for some tasks and a poor choice for others.

- If your primary focus is chemical resistance in a static, low-load application: PTFE is an excellent choice for things like tank liners or static gaskets, where its inertness is paramount and mechanical stress is minimal.

- If your primary focus is a dynamic seal or bearing: You must use a reinforced grade of PTFE and account for a finite service life due to eventual wear and creep.

- If your primary focus requires a rigid, weldable, or easily bonded component: You should seek an alternative polymer, as PTFE's inherent fabrication and mechanical limitations will be a significant barrier.

Understanding these limitations allows you to leverage PTFE's unique strengths without being compromised by its inherent weaknesses.

Summary Table:

| Disadvantage Category | Key Weaknesses | Impact on Application |

|---|---|---|

| Mechanical Limitations | Creep (deformation under load), Poor abrasion resistance, Softness | Limited use in high-load or dynamic applications; requires reinforcement |

| Fabrication Challenges | Cannot be welded, Difficult to bond with adhesives | Complex assemblies are hard to create; increases production complexity and cost |

| Environmental Vulnerabilities | Poor resistance to high-energy radiation (e.g., gamma rays) | Unsuitable for radiation-intensive environments like nuclear or aerospace |

Need high-performance PTFE components that overcome these limitations? At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your components are designed to handle mechanical stress, resist abrasion, and meet exact specifications. Don't let PTFE's weaknesses compromise your project—contact us today to discuss your custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE utilized in the medical and pharmaceutical industries? Ensure Purity and Biocompatibility

- What are the different formulations of PTFE available? Find the Right PTFE for Your Application

- What are some alternative materials to Teflon (PTFE)? Find the Right Fluoropolymer for Your Needs

- What are the hydrophobic properties of PTFE? The Science of Permanent Water Repellency

- What are the mechanical limitations of PTFE? Navigating Its Low Strength and Creep

- Are there references available for PTFE chemical compatibility? Ensure Material Safety with the Right Guide

- What are the different grades of PTFE and their applications? Choose the Right Material for Your Industry

- What are the key properties of PTFE that make it suitable for liners? Superior Chemical & Thermal Resistance