The primary disadvantages of PTFE lined dual plate check valves are their limited operational temperature range, a susceptibility to liner damage from excessive pressure or thermal shock, and a higher initial purchase cost. While offering superior chemical resistance, these limitations define the specific applications where they are, and are not, the optimal choice.

The core issue is that the PTFE liner, which provides excellent corrosion resistance, is also the valve's main point of vulnerability. Its physical limitations regarding temperature and pressure create a clear boundary for its effective use.

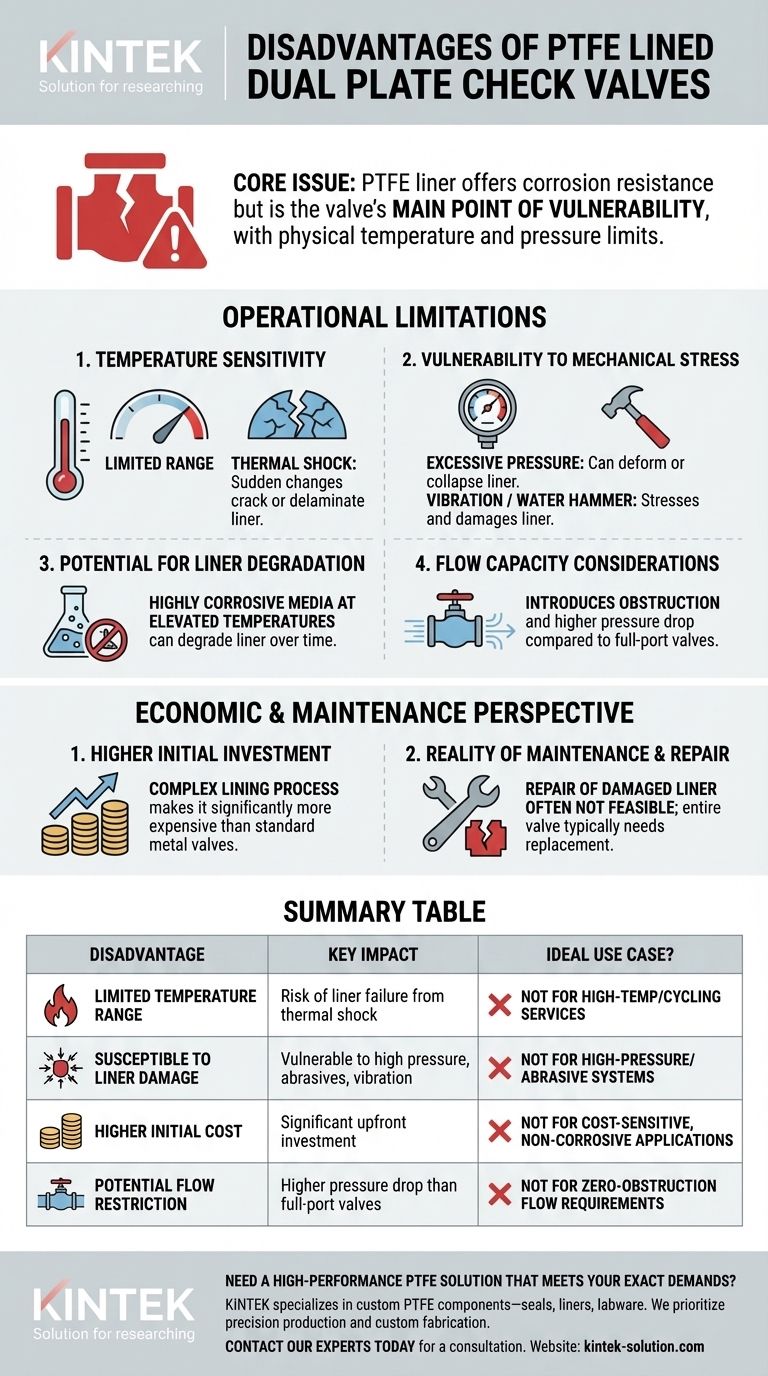

Analyzing the Operational Limitations

While PTFE is a robust material for chemical applications, its physical properties introduce specific constraints that are critical to understand before specification.

Temperature Sensitivity

PTFE has a defined and relatively narrow temperature range compared to metallic components. Exceeding these limits can lead to liner failure.

Sudden, rapid changes in temperature, known as thermal shock, can cause the liner to crack or delaminate from the valve body, leading to immediate failure.

Vulnerability to Mechanical Stress

The PTFE liner can be damaged by pressures that exceed the valve's design specifications. This can cause the liner to deform or collapse, compromising the seal.

Excessive vibration or water hammer events can also stress the liner. Unlike a solid metal valve, a lined valve is more susceptible to damage from these mechanical forces.

Potential for Liner Degradation

While PTFE is resistant to most chemicals, certain highly corrosive media, particularly at elevated temperatures, can still degrade the liner over time.

This makes it crucial to verify material compatibility not just with the chemical itself, but under the specific operating conditions of temperature and pressure.

Flow Capacity Considerations

Compared to full-port valves like certain ball or gate valves, a dual plate check valve inherently introduces some obstruction to the flow path.

While its design is generally efficient for a check valve, it is not a zero-obstruction solution and results in a pressure drop that must be accounted for in system design.

The Economic and Maintenance Perspective

The specialized nature of these valves has direct consequences for both initial cost and long-term maintenance strategies.

Higher Initial Investment

The process of lining a valve body with a high-performance polymer like PTFE is complex and expensive. This results in a significantly higher upfront cost compared to standard carbon steel or stainless steel check valves.

This cost must be justified by the need for superior corrosion resistance that prevents frequent replacement of cheaper alternatives.

The Reality of Maintenance and Repair

The non-stick properties of PTFE reduce build-up and can lower routine maintenance needs.

However, if the liner is damaged, repair is often not feasible. The entire valve typically needs to be replaced, which can lead to higher long-term costs if the valve is misapplied in a high-stress environment.

Understanding the Trade-offs

The decision to use a PTFE lined dual plate check valve hinges on a clear-eyed assessment of its strengths versus its weaknesses for your specific service. Its limitations make it unsuitable for certain common industrial conditions.

Avoid in High-Temperature or Cycling Services

If your process operates near or above the maximum temperature rating for PTFE, or if it experiences rapid temperature swings, this valve is a high-risk choice. A valve made from a suitable metal alloy is a safer alternative.

Avoid in High-Pressure or Abrasive Systems

Systems with pressures that may spike beyond the valve's rating or that contain abrasive solids can easily damage the liner. Abrasives will erode the soft PTFE lining quickly, leading to premature failure.

Avoid in Cost-Sensitive, Non-Corrosive Applications

If the fluid being handled is not corrosive (e.g., water, air, steam), the premium cost of a PTFE lined valve provides no tangible benefit. A standard, unlined valve is the more logical and economical solution.

Making the Right Choice for Your Application

Ultimately, the correct valve choice depends on balancing performance requirements with operational realities.

- If your primary focus is handling highly corrosive media at moderate temperatures: This valve is an excellent choice, providing a long service life where other materials would fail.

- If your system experiences high pressures, vibration, or thermal shock: You must carefully evaluate the risk of liner damage and consider robust, solid alloy valve alternatives.

- If budget is the main constraint and the media is non-corrosive: A standard unlined check valve will provide the necessary function at a fraction of the cost.

Choosing the right valve requires understanding that its most valuable feature—the liner—is also its most significant limitation.

Summary Table:

| Disadvantage | Key Impact | Ideal Use Case? |

|---|---|---|

| Limited Temperature Range | Risk of liner failure from thermal shock | Not for high-temp or cycling services |

| Susceptible to Liner Damage | Vulnerable to high pressure, abrasives, vibration | Not for high-pressure/abrasive systems |

| Higher Initial Cost | Significant upfront investment | Not for cost-sensitive, non-corrosive applications |

| Potential Flow Restriction | Higher pressure drop than full-port valves | Not for zero-obstruction flow requirements |

Need a High-Performance PTFE Solution That Meets Your Exact Demands?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand that selecting the right material is critical to your application's success.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your components perform reliably under your specific operating conditions.

Let us help you optimize your system's performance and longevity. Contact our experts today for a consultation on your custom PTFE needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability