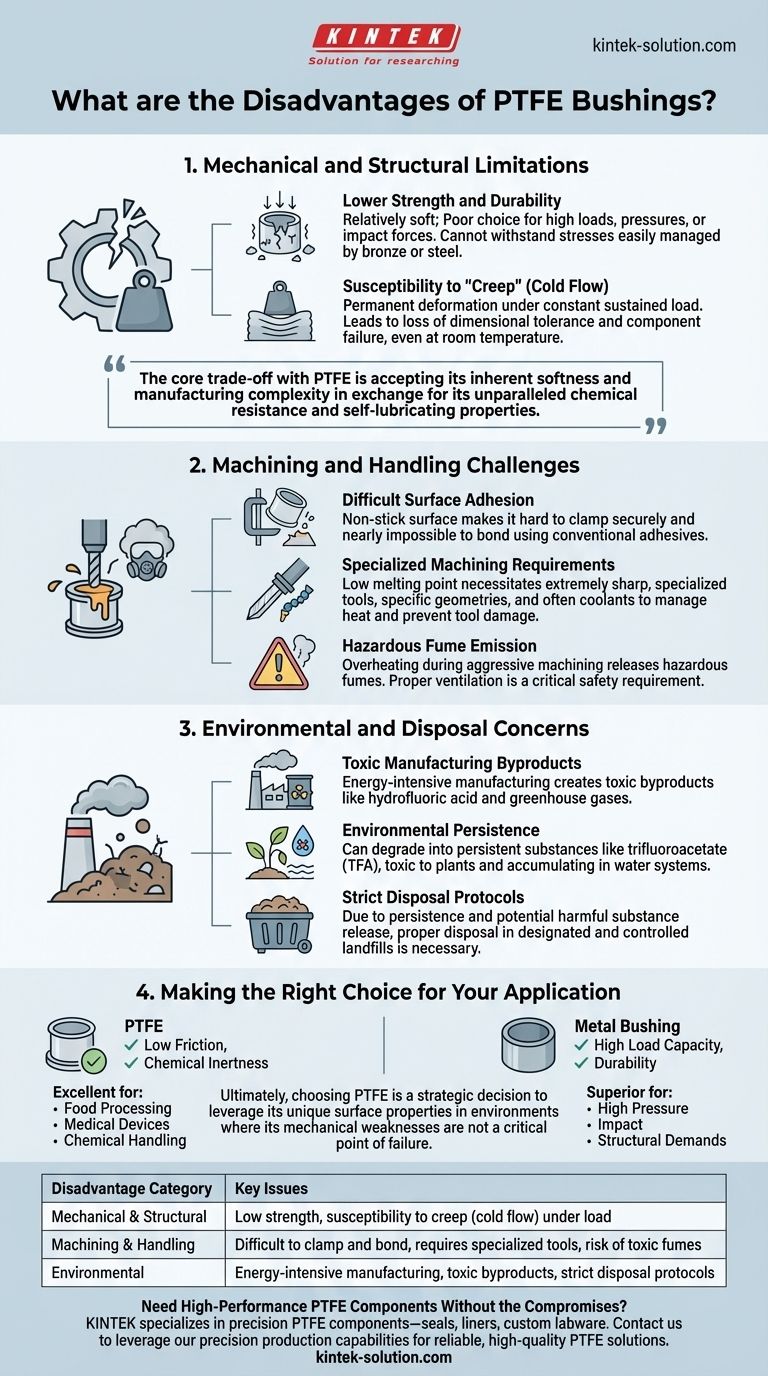

While valued for their extremely low friction, the primary disadvantages of PTFE bushings are their lower mechanical strength compared to metal alternatives, significant challenges in machining and handling, and notable environmental concerns related to their manufacturing and disposal. These factors make them unsuitable for high-load applications and require specialized workshop practices.

The core trade-off with PTFE is accepting its inherent softness and manufacturing complexity in exchange for its unparalleled chemical resistance and self-lubricating properties.

Mechanical and Structural Limitations

The most significant drawback of PTFE is its relative lack of structural rigidity, especially when compared to traditional metal bushings like bronze.

Lower Strength and Durability

PTFE is a relatively soft material. It cannot withstand the high loads, pressures, or impact forces that a bronze or steel bushing can easily manage.

This makes pure PTFE a poor choice for applications requiring high structural integrity or resistance to physical deformation under stress.

Susceptibility to "Creep"

A phenomenon known as creep (or cold flow) is a major concern with PTFE. Under a constant, sustained load, the material can slowly deform permanently, even at room temperature.

This gradual deformation can lead to a loss of dimensional tolerance and eventual failure of the component, a risk not present in most metal alloys.

Machining and Handling Challenges

Working with PTFE is fundamentally different from working with metals and presents a unique set of practical challenges that can increase complexity and cost.

Difficult Surface Adhesion

The non-stick, slippery surface that makes PTFE so valuable in application also makes it difficult to work with. The material is hard to clamp securely for machining and nearly impossible to bond using conventional adhesives.

Specialized Machining Requirements

PTFE's low melting point means it can easily melt from the friction of cutting tools, leading to a poor surface finish and tool damage.

This necessitates the use of extremely sharp, specialized cutting tools, specific geometries, and often the application of coolants to manage heat during the process.

Hazardous Fume Emission

When overheated during aggressive machining or in case of a fire, PTFE can decompose and release hazardous fumes that are toxic when inhaled.

Proper, effective ventilation is not just recommended—it is a critical safety requirement for any operation that involves heating or high-speed cutting of PTFE.

Environmental and Disposal Concerns

The lifecycle of PTFE, from creation to disposal, carries significant environmental liabilities that are increasingly important considerations in material selection.

Toxic Manufacturing Byproducts

The manufacturing process for PTFE is energy-intensive and creates toxic byproducts, including highly corrosive hydrofluoric acid and greenhouse gases.

Environmental Persistence

If PTFE enters the environment, it can degrade into other persistent substances like trifluoroacetate (TFA), which is known to be toxic to plants and accumulates in water systems.

Strict Disposal Protocols

Due to its persistence and potential for releasing harmful substances, PTFE components cannot be disposed of casually. Proper disposal, typically in a designated and controlled landfill, is necessary to prevent environmental contamination.

Making the Right Choice for Your Application

Selecting the correct bushing material requires balancing the unique benefits of PTFE against its significant limitations.

- If your primary focus is low friction and chemical inertness: PTFE is an excellent choice for applications in food processing, medical devices, or chemical handling where self-lubrication and purity are paramount.

- If your primary focus is high load capacity and durability: A metal bushing, such as bronze, is the far superior and safer choice for any application involving high pressure, impact, or structural demands.

- If your primary focus is simple fabrication and handling: The specialized requirements for machining PTFE can make traditional materials a more practical and cost-effective option for standard workshop environments.

Ultimately, choosing PTFE is a strategic decision to leverage its unique surface properties in environments where its mechanical weaknesses are not a critical point of failure.

Summary Table:

| Disadvantage Category | Key Issues |

|---|---|

| Mechanical & Structural | Low strength, susceptibility to creep (cold flow) under load |

| Machining & Handling | Difficult to clamp and bond, requires specialized tools, risk of toxic fumes |

| Environmental | Energy-intensive manufacturing, toxic byproducts, strict disposal protocols |

Need High-Performance PTFE Components Without the Compromises?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our expertise in custom fabrication from prototypes to high-volume orders ensures you get components that meet your exact specifications while mitigating common PTFE challenges.

Contact us today to discuss your project and leverage our precision production capabilities for reliable, high-quality PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What is the difference between PTFE sheets and Teflon paper? A Guide to Choosing the Right Form

- Why are PTFE energized seals a preferred choice for aerospace engineers? Ensure Reliability in Extreme Conditions

- How does heat exposure affect PTFE seals? Mastering Thermal Expansion for Superior Sealing

- In which industries are PTFE gaskets commonly used? Ensuring Safety & Purity in Demanding Applications

- What factors should be considered when selecting Teflon encapsulated O-rings? Ensure Chemical and Thermal Reliability

- What are the key properties of PTFE envelope gaskets? Ensure Reliable Sealing in Demanding Environments

- What are the pressure-temperature limitations for polymer seats in high performance butterfly valves? Avoid Costly Valve Failures

- How does the chemical stability of PTFE oil seals compare to conventional oil seals? Superior Performance in Harsh Environments