At its core, Polytetrafluoroethylene (PTFE) is available in two primary categories: virgin grade and various filled grades. Virgin PTFE is the pure, unmodified polymer, prized for its extreme chemical inertness and low friction. Filled grades are composites that add materials like glass, carbon, or bronze to the PTFE base to enhance specific mechanical properties such as wear resistance or compressive strength.

The fundamental decision in selecting a PTFE variant is a trade-off. You must choose between the absolute chemical purity and electrical insulation of virgin PTFE and the superior mechanical performance and wear resistance offered by filled grades.

The Foundation: Understanding Virgin PTFE

Virgin PTFE is the basis from which all other variants are derived. Its unique molecular structure gives it a set of remarkable characteristics that make it suitable for a wide range of demanding applications.

Unmatched Chemical and Electrical Properties

PTFE is famous for being one of the most chemically inert materials known. It resists nearly all industrial chemicals and solvents, making it ideal for seals, gaskets, and linings in corrosive environments.

It is also an excellent electrical insulator with outstanding dielectric properties, which is why it's used for high-frequency insulation and components. It is hydrophobic (repels water) and approved by the FDA for food contact.

The Lowest Coefficient of Friction

Of any known solid material, PTFE has one of the lowest coefficients of friction. This property, often described as being "slippery," is why it is used for non-stick surfaces and low-friction bearings.

Extreme Temperature Resilience

Virgin PTFE performs reliably across an exceptionally wide temperature range, remaining functional from –200°C to +260°C (–328°F to +500°F). It also resists ignition and does not promote the spread of flames, holding a UL94 V-0 rating.

Common Forms and Applications

Due to its softness and formability, virgin PTFE is manufactured into various components. These include tubing, heat-shrink sleeves, tape, sheets, O-rings, V-rings, and custom-machined insulators and seals.

Enhancing Performance: Filled PTFE Variants

While virgin PTFE has extraordinary properties, it is mechanically soft. Fillers are added to the PTFE base to overcome these limitations, creating composite materials with targeted performance enhancements.

The Purpose of Fillers

The primary reason to use a filled grade is to improve mechanical properties. Fillers significantly increase resistance to wear, "cold flow" or creep (deformation under load), and compressive strength.

Glass-Filled PTFE

Glass fibers are a common filler used to drastically increase stiffness and wear resistance. This grade is well-suited for applications requiring higher compressive strength, but it can be abrasive to mating surfaces.

Carbon-Filled PTFE

Adding carbon increases compressive strength, hardness, and wear resistance. Carbon-filled PTFE has excellent chemical resistance and its conductivity can be tailored, making it suitable for anti-static applications.

Graphite-Filled PTFE

Graphite is often used as a filler to further reduce the coefficient of friction and improve wear properties, particularly in dynamic sealing applications. It is less abrasive than glass and is sometimes combined with carbon or glass fibers.

Bronze-Filled PTFE

Adding bronze powder to PTFE creates a material with a much higher compressive strength and resistance to creep. It also has higher thermal conductivity, helping to dissipate heat in high-speed applications. However, its chemical resistance is lower than other grades.

Understanding the Trade-offs and Limitations

No material is perfect. Understanding PTFE's inherent weaknesses is critical to selecting the right grade and avoiding application failure.

The Primary Weakness: Deformation Under Load

The most significant limitation of virgin PTFE is its tendency to deform, or "cold flow," under sustained pressure. This makes it unsuitable for high-load structural applications without reinforcement, which is the primary driver for using filled grades.

Poor Radiation Resistance

PTFE does not hold up well to high-energy radiation. Gamma or electron-beam radiation can cause the polymer's molecules to break down, leading to embrittlement and a loss of mechanical properties.

Compromises with Filled Grades

While fillers improve mechanical strength, they can compromise some of PTFE's core benefits. For example, bronze-filled PTFE has reduced chemical resistance, and glass-filled PTFE can be abrasive to other parts. The filler material inherently dilutes the pure PTFE, slightly altering its chemical and electrical profile.

Specific Chemical Vulnerabilities

Although exceptionally inert, PTFE is not invincible. It can be attacked by highly reactive agents like elemental fluorine, chlorine trifluoride, and molten alkali metals under specific conditions of high pressure and temperature.

Making the Right Choice for Your Application

Your selection should be guided by the most critical performance demand of your project.

- If your primary focus is chemical purity or electrical insulation: Choose virgin PTFE for its unmatched inertness and superior dielectric properties.

- If your primary focus is wear resistance and strength under load: Select a filled grade like glass-filled PTFE for hardness or carbon-filled for compressive strength.

- If your primary focus is managing heat and creep in moving parts: Consider bronze-filled PTFE for its high thermal conductivity, but verify chemical compatibility.

- If your primary focus is a low-friction surface with improved durability: A graphite-filled or carbon-filled grade offers a strong balance for dynamic seals and bearings.

Ultimately, choosing the correct PTFE grade requires matching the specific variant to the precise mechanical, chemical, and thermal demands of its operating environment.

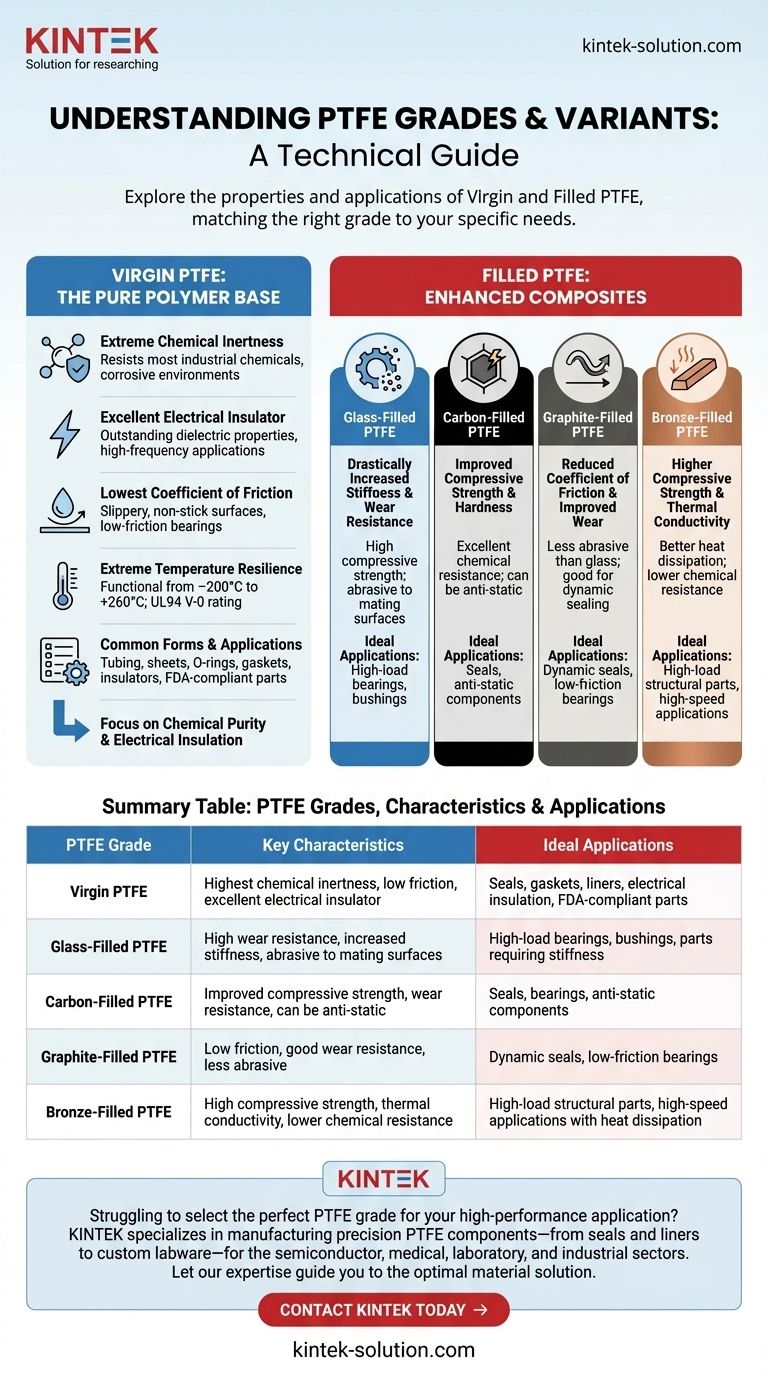

Summary Table:

| PTFE Grade | Key Characteristics | Ideal Applications |

|---|---|---|

| Virgin PTFE | Highest chemical inertness, low friction, excellent electrical insulator | Seals, gaskets, liners, electrical insulation, FDA-compliant parts |

| Glass-Filled PTFE | High wear resistance, increased stiffness, abrasive to mating surfaces | High-load bearings, bushings, parts requiring stiffness |

| Carbon-Filled PTFE | Improved compressive strength, wear resistance, can be anti-static | Seals, bearings, anti-static components |

| Graphite-Filled PTFE | Low friction, good wear resistance, less abrasive | Dynamic seals, low-friction bearings |

| Bronze-Filled PTFE | High compressive strength, thermal conductivity, lower chemical resistance | High-load structural parts, high-speed applications with heat dissipation |

Struggling to select the perfect PTFE grade for your high-performance application? KINTEK specializes in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact mechanical, chemical, and thermal requirements. Let our expertise guide you to the optimal material solution—contact us today to discuss your project!

Visual Guide

Related Products

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- How do fillers enhance the properties of PTFE? Improve Wear, Strength, and Thermal Performance

- What are the benefits of using Teflon in fiberglass? Achieve Unmatched Durability and Chemical Resistance

- What are the unique characteristics of PTFE? Leverage Extreme Chemical & Thermal Resistance

- What are the advantages of using PTFE/Teflon? Unlock Superior Chemical & Thermal Stability

- What are the benefits of molybdenum disulfide (MoS2)-filled PTFE? Enhance Durability & Performance

- Why are fillers added to PTFE? Enhance Performance for Demanding Applications

- Which industries commonly use PTFE plastic? A Guide to Its Critical Applications