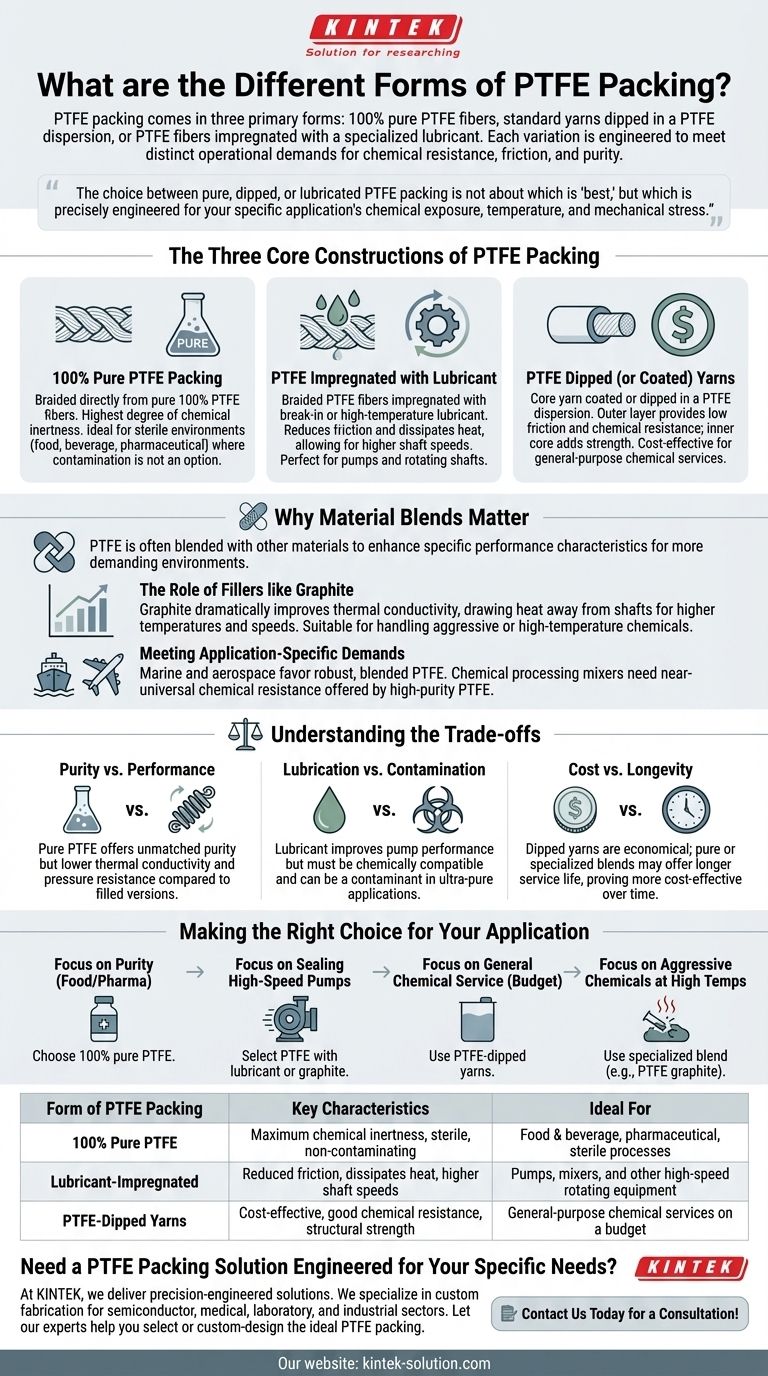

PTFE packing comes in three primary forms. It is constructed from 100% pure PTFE fibers, made from standard yarns that are dipped in a PTFE dispersion, or consists of PTFE fibers that have been impregnated with a specialized lubricant. Each variation is engineered to meet distinct operational demands for chemical resistance, friction, and purity.

The choice between pure, dipped, or lubricated PTFE packing is not about which is "best," but which is precisely engineered for your specific application's chemical exposure, temperature, and mechanical stress.

The Three Core Constructions of PTFE Packing

The functional differences between types of PTFE packing are rooted in their material composition and construction method. Understanding these distinctions is key to selecting the right seal for your equipment.

100% Pure PTFE Packing

This form is braided directly from pure, 100% PTFE fibers, also known as Teflon.

Because it contains no other additives or materials, it offers the highest degree of chemical inertness. It is highly resistant to aggressive acids, chemicals, and gases.

This purity makes it the standard choice for sterile environments, such as the food and beverage, and pharmaceutical manufacturing industries where contamination is not an option.

PTFE Impregnated with Lubricant

This packing starts with braided PTFE fibers that are then impregnated with a break-in or high-temperature lubricant.

The primary role of the lubricant is to reduce friction and dissipate heat, especially in applications involving rotating shafts, such as pumps.

This significantly reduces wear on equipment shafts and allows for higher shaft speeds compared to non-lubricated packing.

PTFE Dipped (or Coated) Yarns

This construction uses a core yarn made from a standard synthetic material, which is then coated or dipped in a PTFE dispersion.

The outer PTFE coating provides the critical low-friction surface and chemical resistance, while the inner core provides the packing's structural bulk and strength.

This method often results in a more cost-effective packing solution for general-purpose chemical services where the extreme purity of 100% PTFE is not required.

Why Material Blends Matter

Beyond the three core constructions, PTFE is often blended with other materials to enhance specific performance characteristics for more demanding environments.

The Role of Fillers like Graphite

PTFE is frequently combined with fillers like graphite to create a composite packing material.

Graphite dramatically improves the thermal conductivity of the packing. This allows it to draw heat away from the shaft more effectively, making it suitable for higher temperatures and speeds.

This type of specialized blend is often required for equipment handling aggressive or high-temperature chemicals where pure PTFE might fail.

Meeting Application-Specific Demands

The choice of packing is dictated entirely by its environment.

Marine and aerospace applications demand reliability under extreme pressures and corrosive conditions, favoring robust, often blended, PTFE packings.

Conversely, chemical processing reactors and mixers primarily need the near-universal chemical resistance offered by high-purity PTFE.

Understanding the Trade-offs

Selecting the ideal packing requires balancing performance characteristics against the specific needs of the application. There is no single solution that fits all scenarios.

Purity vs. Performance

Pure PTFE offers unmatched chemical resistance and is essential for sanitary applications. However, it has lower thermal conductivity and can be more susceptible to deformation under very high pressures compared to filled versions.

Lubrication vs. Contamination

Lubricated packing provides superior performance for pumps and other rotating equipment. The trade-off is that the lubricant must be chemically compatible with the process fluid and could be a potential contaminant in ultra-pure applications.

Cost vs. Longevity

While PTFE-dipped yarns are often more economical upfront, a 100% pure or specialized blend packing may offer a significantly longer service life in a demanding environment, proving more cost-effective over time.

Making the Right Choice for Your Application

To select the correct packing, analyze the core requirements of your system: chemical compatibility, temperature, pressure, and shaft speed.

- If your primary focus is food, beverage, or pharmaceutical purity: Choose a packing made from 100% pure PTFE fibers to ensure non-toxicity and prevent contamination.

- If your primary focus is sealing high-speed pumps: Select a PTFE packing impregnated with a compatible lubricant or filled with graphite to manage friction and dissipate heat.

- If your primary focus is general chemical service on a budget: A standard yarn dipped in a PTFE dispersion provides excellent chemical resistance in a cost-effective form.

- If your primary focus is handling aggressive chemicals at high temperatures: Use a specialized blend, such as PTFE graphite packing, for enhanced thermal and chemical stability.

Understanding these variations allows you to select a sealing solution precisely engineered for your equipment's specific operational needs.

Summary Table:

| Form of PTFE Packing | Key Characteristics | Ideal For |

|---|---|---|

| 100% Pure PTFE | Maximum chemical inertness, sterile, non-contaminating | Food & beverage, pharmaceutical, sterile processes |

| Lubricant-Impregnated | Reduced friction, dissipates heat, higher shaft speeds | Pumps, mixers, and other high-speed rotating equipment |

| PTFE-Dipped Yarns | Cost-effective, good chemical resistance, structural strength | General-purpose chemical services on a budget |

Need a PTFE Packing Solution Engineered for Your Specific Needs?

At KINTEK, we don't just supply PTFE components—we deliver precision-engineered solutions. Whether your application demands the absolute purity of 100% PTFE for pharmaceutical use, the high-speed performance of lubricant-impregnated seals for pumps, or a cost-effective dipped-yarn solution for chemical processing, we can help.

We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your equipment in the semiconductor, medical, laboratory, and industrial sectors.

Let our experts help you select or custom-design the ideal PTFE packing. Contact us today for a consultation!

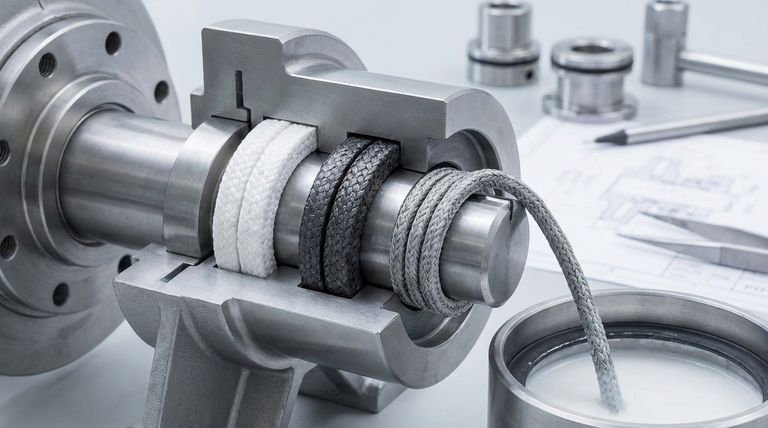

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications