In the food industry, Teflon (PTFE) sheets are primarily used as durable, non-stick liners for surfaces that come into direct contact with food during processing. Their key applications include lining baking sheets, trays, and conveyor belts, as well as coating specific machinery parts like molds, augers, and cutting blades. This prevents food from sticking, which simplifies cleanup and improves operational efficiency.

The core value of Teflon in food processing extends beyond a simple non-stick surface. It is a strategic material choice that directly enhances production efficiency, ensures product uniformity, and simplifies critical sanitation procedures by preventing residue buildup.

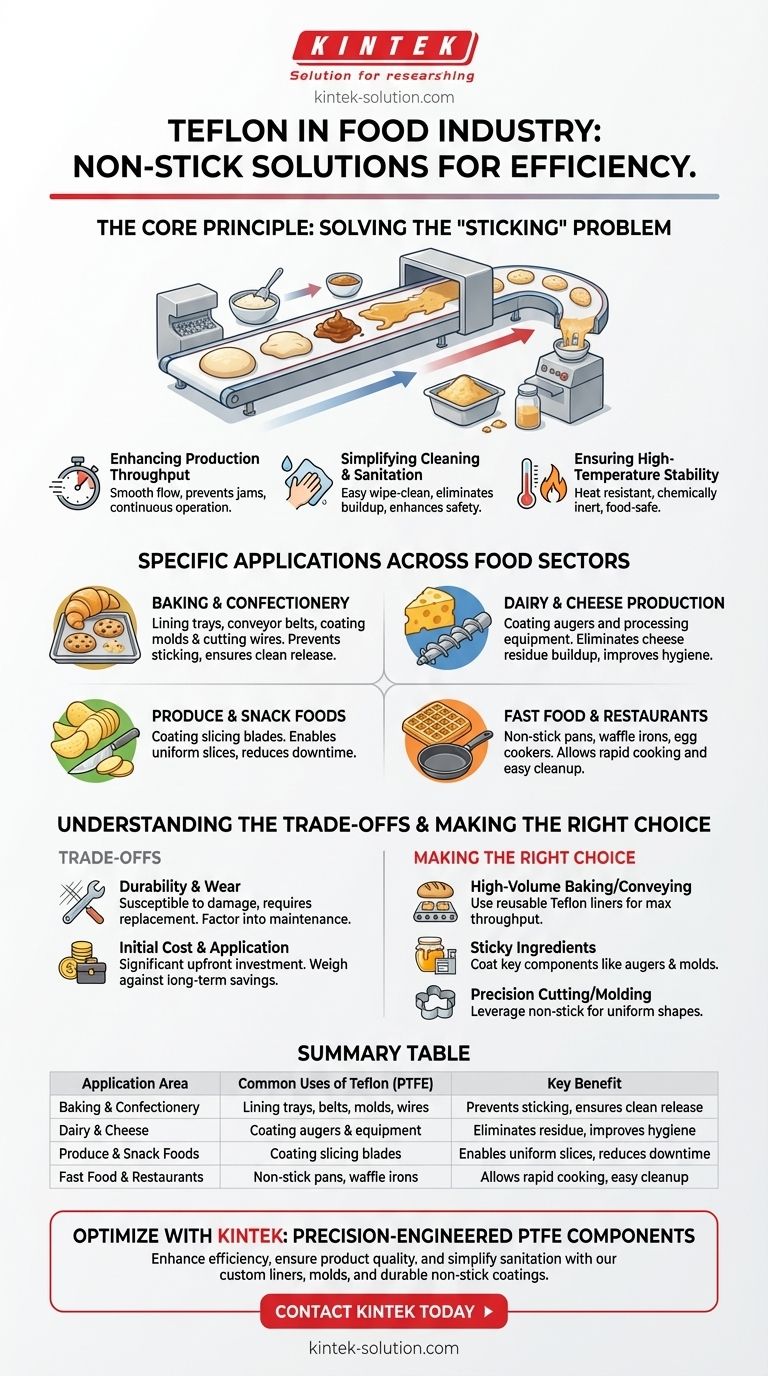

The Core Principle: Solving the "Sticking" Problem

The fundamental challenge in high-volume food production is managing sticky ingredients. Residue from dough, sugar, cheese, and other products can slow down machinery, cause product loss, and create sanitation issues. Teflon's unique properties directly address these challenges.

Enhancing Production Throughput

By creating a surface with extremely low friction, Teflon ensures that food products move smoothly through the production line. This is critical for conveyor belts, molds, and cutting equipment.

A clean, non-stick surface prevents jams and buildup, allowing machinery to run continuously at optimal speed without frequent stops for cleaning.

Simplifying Cleaning and Sanitation

Surfaces lined with Teflon are exceptionally easy to clean. Food residue does not adhere, meaning it can be wiped away with minimal effort, reducing labor costs and water usage.

This ease of cleaning also enhances food safety by eliminating crusted-on material where bacteria could otherwise accumulate.

Ensuring High-Temperature Stability

Teflon is chemically inert and remains stable at the high temperatures required for baking and cooking.

It will not break down or transfer harmful substances to food, making it a reliable and food-safe choice for ovens and other heated processing equipment.

Specific Applications Across Food Sectors

While the principle is universal, the application of Teflon sheets and coatings is tailored to the specific needs of different segments within the food industry.

Baking and Confectionery

In large-scale baking, Teflon liners on trays and conveyor belts are standard for preventing cookies, pastries, and breads from sticking.

Sugar producers coat cube molds with Teflon for easy release, while cookie manufacturers use Teflon-coated wires to ensure dough is cut cleanly and uniformly.

Dairy and Cheese Production

Cheese manufacturers often coat processing augers with Teflon. This prevents the buildup of dried cheese crust, which can clog machinery and compromise hygiene.

Produce and Snack Foods

Potato chip manufacturers coat slicing knives with Teflon. This reduces starchy residue on the blades, resulting in cleaner, more uniform slices and less production downtime.

Fast Food and Restaurants

In commercial kitchens, Teflon is used on high-volume equipment like egg scrambler pans and waffle molds. The non-stick surface allows for rapid cooking and quick turnover with minimal cleaning between uses.

Understanding the Trade-offs

While highly effective, implementing Teflon is a technical decision that involves considering its limitations. Being aware of these factors ensures you are using the material correctly.

Durability and Mechanical Wear

Teflon surfaces are not indestructible. They can be damaged by sharp utensils, abrasive cleaners, or constant, high-pressure friction.

Over time, coatings and sheets will wear down and require replacement. This should be factored into maintenance schedules and operating budgets.

Initial Cost and Application

The initial cost of purchasing Teflon liners or coating existing equipment can be significant.

This investment must be weighed against the long-term savings gained from increased efficiency, reduced product waste, and lower cleaning and labor costs.

Making the Right Choice for Your Process

Ultimately, using Teflon is about optimizing a specific production goal. Your primary operational challenge will determine how you should leverage this material.

- If your primary focus is high-volume baking or conveying: Reusable Teflon liners are an industry standard for maximizing throughput and minimizing cleaning downtime.

- If your primary focus is processing sticky ingredients like cheese or sugar: Coating key machinery components like augers and molds is essential to prevent costly buildup and maintain consistent operation.

- If your primary focus is precision cutting or molding: The non-stick surface of Teflon ensures clean release and uniform product shapes, from potato chips to confectionery.

Choosing the right application of Teflon is a direct investment in a more efficient, clean, and reliable food production line.

Summary Table:

| Application Area | Common Uses of Teflon (PTFE) | Key Benefit |

|---|---|---|

| Baking & Confectionery | Lining trays, conveyor belts, coating molds & cutting wires | Prevents dough/sugar sticking, ensures clean product release |

| Dairy & Cheese | Coating augers and processing equipment | Eliminates cheese residue buildup, improves hygiene |

| Produce & Snack Foods | Coating slicing blades (e.g., for potato chips) | Enables uniform slices, reduces downtime |

| Fast Food & Restaurants | Non-stick pans, waffle irons, egg cookers | Allows rapid cooking and easy cleanup |

Optimize your food production line with precision-engineered PTFE components from KINTEK.

Whether you need custom Teflon liners for conveyor belts, coated molds for confectionery, or durable non-stick coatings for machinery parts, KINTEK delivers solutions that enhance efficiency, ensure product quality, and simplify sanitation. We specialize in fabricating high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors, with expertise in custom projects from prototypes to high-volume orders.

Contact KINTEK today to discuss how our PTFE solutions can solve your specific sticking challenges and boost your operational throughput.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications