Specifically, modified PTFE gaskets are used in demanding applications like corrosion-resistant pipelines, pumps, and valves, as well as in highly specialized equipment for control radar and high-frequency communications. Their enhanced physical properties solve sealing challenges where standard materials might fail under pressure or temperature fluctuations.

The core value of modified PTFE gaskets lies in their enhanced physical properties over standard PTFE. While sharing the same exceptional chemical and thermal resistance, modifications reduce creep and improve dimensional stability, making them superior for high-pressure, high-temperature, and specialized electronic applications.

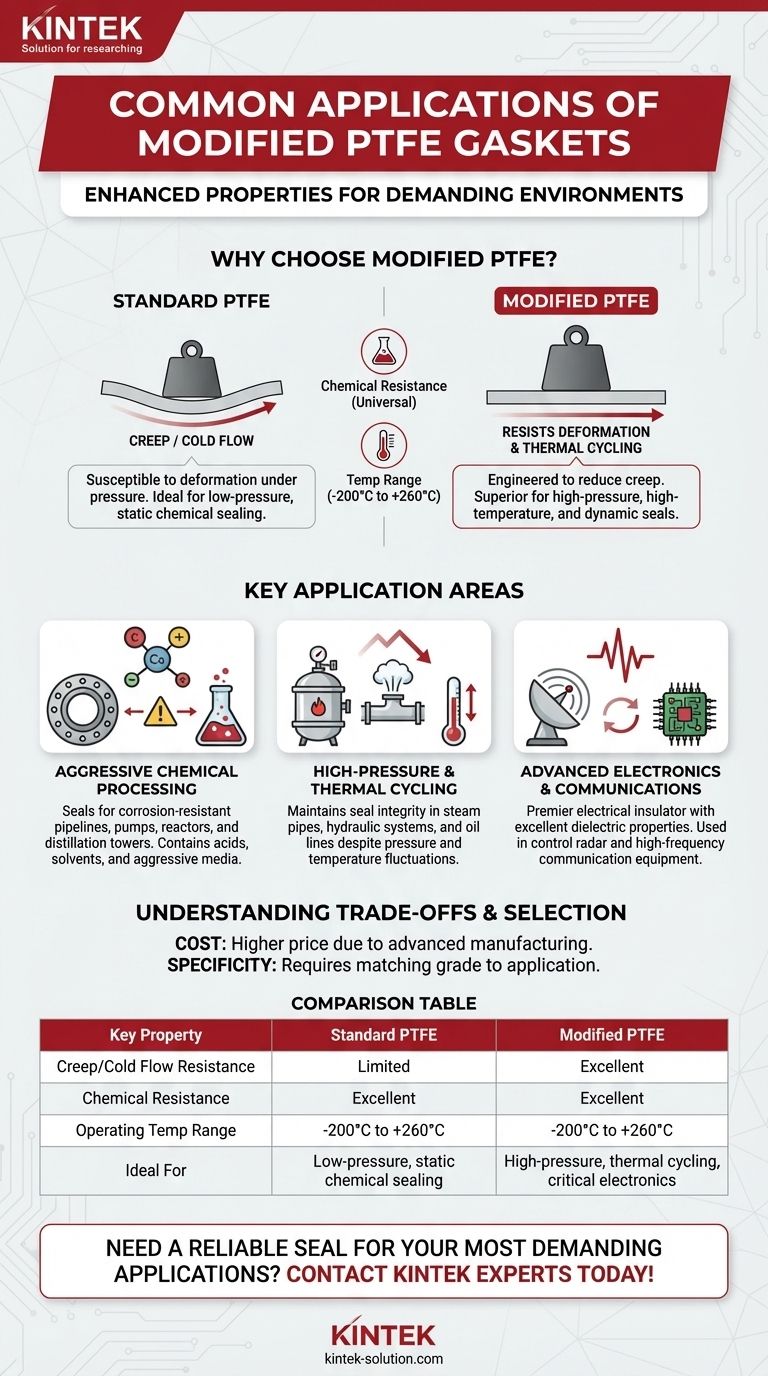

Why Choose Modified PTFE Over Standard PTFE?

Understanding the distinction between standard and modified PTFE is crucial for selecting the right gasket. The choice hinges on the mechanical demands of your application.

The Core Advantage: Reduced Creep and Cold Flow

Standard PTFE, while chemically robust, can be susceptible to creep or "cold flow." This is the tendency of the material to slowly deform over time when under constant pressure, such as when compressed in a flange.

Modified PTFE is engineered to counteract this. By altering the polymer's structure or adding fillers, it gains significantly better dimensional stability and resistance to deformation, ensuring a more reliable and long-lasting seal.

Superior Sealing in Demanding Conditions

This resistance to creep makes modified PTFE the superior choice for services involving thermal cycling (frequent heating and cooling) or high pressures.

Where a standard gasket might loosen and require re-torquing, a modified PTFE gasket maintains its integrity, providing a more reliable seal in equipment like high-pressure vessels, heat exchangers, and critical pipeline flanges.

Retaining PTFE's Legendary Resistance

Crucially, these mechanical improvements are achieved without sacrificing the properties that make PTFE so valuable in the first place.

Modified PTFE retains the outstanding chemical inertness, wide operating temperature range (-200°C to +260°C), and excellent electrical insulation of virgin PTFE.

Key Application Areas Explained

The enhanced properties of modified PTFE make it the go-to material for several critical industrial sectors.

Aggressive Chemical Processing

Due to its near-universal chemical resistance, modified PTFE is used to seal flanges on corrosion-resistant pipelines, pumps, chemical reactors, and distillation towers.

It safely contains acids, solvents, and other aggressive media that would degrade most other sealing materials.

High-Pressure and Thermal Cycling

Applications like steam pipes, aircraft hydraulic systems, and high-pressure oil lines benefit from the material's stability.

The gasket maintains a tight seal despite fluctuations in pressure and temperature, preventing leaks in critical systems where failure is not an option.

Advanced Electronics and Communications

Modified PTFE's excellent dielectric properties make it a premier electrical insulator.

It is used in high-frequency communication equipment and control radar detection systems to protect and isolate sensitive electronic components, ensuring signal integrity and preventing electrical shorts.

Understanding the Trade-offs

While highly effective, modified PTFE is not a universal solution. An objective assessment requires considering its limitations.

Cost Considerations

Modified PTFE gaskets are typically more expensive than their standard counterparts. The advanced manufacturing processes and materials contribute to a higher price point.

For less demanding applications, standard PTFE or another material may be a more cost-effective choice.

Specificity of the Modification

The term "modified" covers a range of materials. PTFE can be filled with glass, carbon, or other agents to enhance specific properties like wear resistance or compressive strength.

Choosing the wrong type of modification can lead to suboptimal performance. It is critical to match the specific grade of modified PTFE to the application's unique demands.

Mechanical Limitations

Despite its improvements, PTFE is still a relatively soft material compared to metals. It is not intended for applications requiring extreme structural strength or rigidity.

Making the Right Choice for Your Goal

Selecting the correct gasket requires matching its properties to the primary challenge you need to solve.

- If your primary focus is sealing aggressive chemicals under high pressure or temperature: Modified PTFE is the superior choice due to its excellent resistance to creep and cold flow.

- If your primary focus is high-frequency electrical insulation: Modified PTFE provides the necessary dielectric strength and physical stability for sensitive electronic equipment.

- If your primary focus is general-purpose chemical sealing in a low-pressure, static environment: Standard PTFE is often sufficient and more cost-effective.

Ultimately, choosing modified PTFE is an investment in long-term seal integrity and reliability for your most critical and demanding applications.

Summary Table:

| Key Property | Standard PTFE | Modified PTFE |

|---|---|---|

| Creep/Cold Flow Resistance | Limited | Excellent |

| Chemical Resistance | Excellent | Excellent |

| Operating Temperature Range | -200°C to +260°C | -200°C to +260°C |

| Ideal For | Low-pressure, static chemical sealing | High-pressure, thermal cycling, critical electronics |

Need a reliable seal for your most demanding applications?

At KINTEK, we specialize in manufacturing high-performance modified PTFE components, including custom gaskets, seals, and liners. Our precision engineering ensures superior dimensional stability and long-term reliability for the semiconductor, medical, laboratory, and industrial sectors.

Whether you require a prototype or a high-volume order, we provide custom fabrication to meet your exact specifications.

Contact our experts today to discuss your sealing challenges and discover the KINTEK advantage!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why are PTFE washers used in the aerospace industry? Ensure Reliability in Extreme Conditions

- What are the benefits of Teflon bellow mechanical seals for manufacturers and suppliers? Unlock New Market Opportunities

- What are the mechanical properties of PTFE that make it durable? Leverage Specialized Resilience

- Why are PTFE gaskets considered safe for sensitive applications? Ensure Purity and Reliability

- What are PTFE O-rings and their properties? A Guide to High-Performance Sealing

- What are the main benefits of using PTFE liners? Achieve Unmatched Chemical and Thermal Resistance

- How does the durability of Teflon sheets benefit printing operations? Boost Quality & Cut Costs

- How does the temperature resistance of PTFE gaskets compare? Unmatched Thermal Stability from -200°C to +260°C