In terms of chemical resistance, Polytetrafluoroethylene (PTFE), commonly known as Teflon, is one of the most inert materials available for industrial use. PTFE balls are exceptionally resistant to nearly all industrial acids, bases, solvents, and corrosive agents. There is no common solvent known that can dissolve PTFE at room temperature.

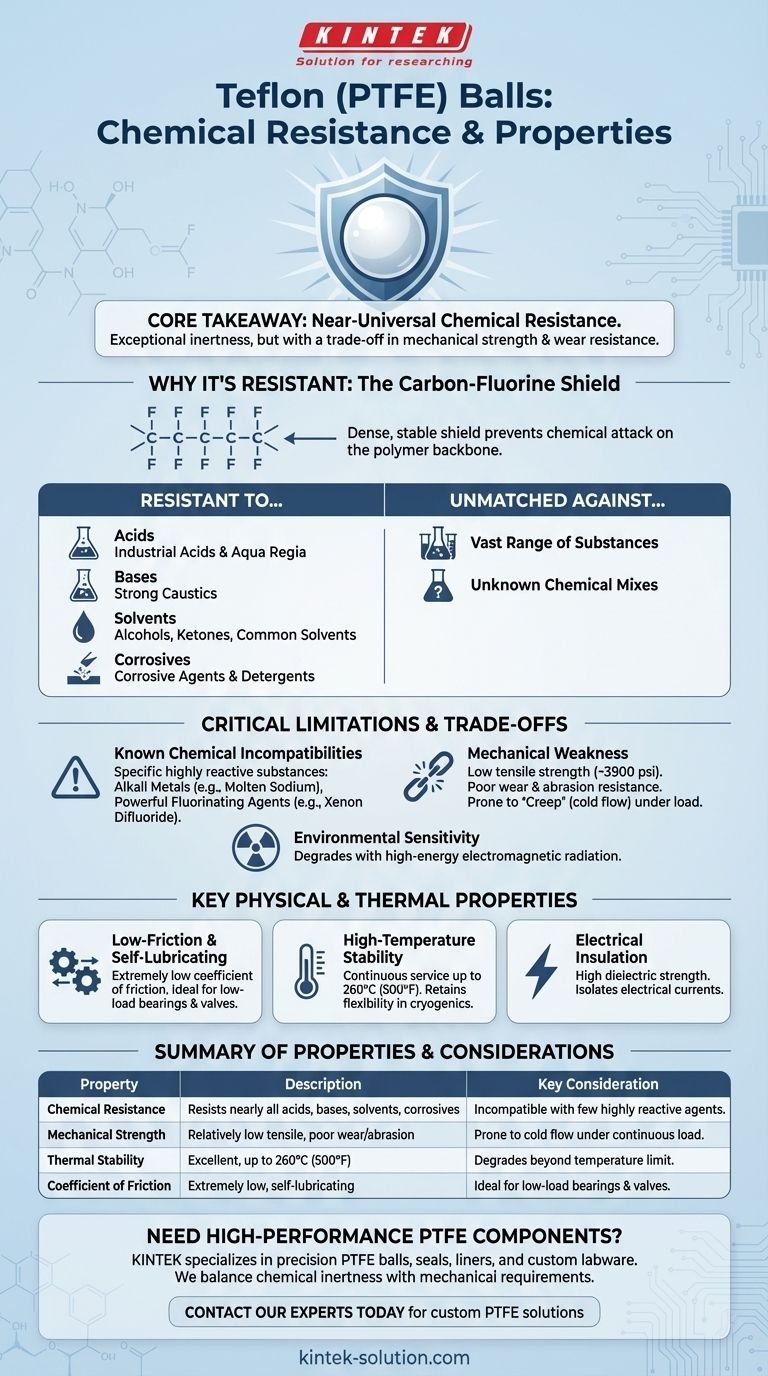

The core takeaway is that PTFE offers near-universal chemical resistance, making it a default choice for chemically harsh environments. However, this exceptional inertness comes with a critical trade-off: lower mechanical strength and wear resistance compared to other engineering plastics.

Understanding PTFE's Chemical Inertness

The remarkable properties of PTFE stem directly from its unique molecular structure. Understanding this is key to appreciating its capabilities and limitations.

The Source of Its Resistance

PTFE is a fluoropolymer. Its structure consists of a long chain of carbon atoms completely shielded by fluorine atoms. The carbon-fluorine bond is one of the strongest single bonds in organic chemistry.

This powerful bond creates a dense, stable, and non-reactive molecular shield, preventing other chemicals from attacking the carbon backbone of the polymer.

Resistance to Common Industrial Chemicals

Because of this structure, PTFE balls are unaffected by a vast range of substances. This includes aggressive acids like aqua regia, strong caustics, alcohols, ketones, and detergents.

For applications involving exposure to a wide or unknown variety of chemicals, PTFE's reliability is nearly unmatched.

Critical Limitations and Exceptions

No material is perfect. While PTFE's chemical resistance is legendary, you must be aware of its specific vulnerabilities and physical trade-offs to use it correctly.

Known Chemical Incompatibilities

PTFE is not completely inert. It is known to react with a small, specific group of highly reactive substances.

These include certain alkali metals (like molten sodium) and extremely powerful fluorinating agents such as xenon difluoride and cobalt(III) fluoride. In almost all standard industrial scenarios, these chemicals are not a concern.

The Trade-off: Mechanical Properties

The most significant trade-off for PTFE's chemical inertness is its relatively poor mechanical strength.

Compared to other engineering plastics, PTFE is softer, has lower tensile strength (around 3900 psi), and exhibits poor wear and abrasion resistance. It can deform under high loads, a phenomenon known as "creep" or cold flow.

Sensitivity to Environmental Factors

The properties of PTFE can also be altered by certain environmental conditions. High-energy electromagnetic radiation can degrade the polymer, weakening its structure.

While it has excellent heat resistance up to 260°C (500°F), its properties will degrade beyond this point.

Key Physical and Thermal Properties

Beyond chemical resistance, several other properties make PTFE balls useful in specific contexts.

Low-Friction and Self-Lubricating

PTFE has one of the lowest coefficients of friction of any solid material. This makes it naturally self-lubricating, which is ideal for low-load bearings, check valves, and applications where external lubricants are undesirable.

High-Temperature Stability

PTFE balls remain stable and functional in continuous service at temperatures up to 260°C (500°F). They also maintain their flexibility at cryogenic temperatures, giving them an extremely wide operating temperature range.

Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. This property makes it valuable for components that must isolate electrical currents while being exposed to chemicals.

Making the Right Choice for Your Application

Selecting the right material requires balancing all performance factors against your primary goal.

- If your primary focus is maximum chemical inertness: PTFE is often the default choice, as long as the few highly reactive chemical exceptions are not present in your system.

- If your application involves significant mechanical stress or abrasion: You must carefully evaluate PTFE's lower wear resistance and consider stronger materials, even if it means a slight compromise on chemical compatibility.

- If you need a component for a high-temperature, low-load environment: PTFE's combination of thermal stability and self-lubrication makes it an ideal candidate, especially in the presence of corrosive agents.

Understanding this balance between exceptional chemical resistance and modest mechanical strength is the key to successfully deploying PTFE in your application.

Summary Table:

| Property | Description | Key Consideration |

|---|---|---|

| Chemical Resistance | Resistant to nearly all industrial acids, bases, solvents, and corrosive agents. | Incompatible with highly reactive fluorinating agents and alkali metals. |

| Mechanical Strength | Relatively low tensile strength and poor wear/abrasion resistance. | Prone to cold flow (creep) under continuous load. |

| Thermal Stability | Excellent; continuous service up to 260°C (500°F). | Properties degrade beyond this temperature limit. |

| Coefficient of Friction | Extremely low, making it self-lubricating. | Ideal for low-load bearings and valves. |

Need high-performance PTFE components that can withstand your toughest chemical challenges?

At KINTEK, we specialize in manufacturing precision PTFE balls, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between chemical inertness and mechanical requirements.

Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components tailored to your specific application's demands, delivering reliability and longevity in even the most corrosive environments.

Contact our experts today to discuss your project requirements and discover how our PTFE solutions can enhance your system's performance and durability.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites