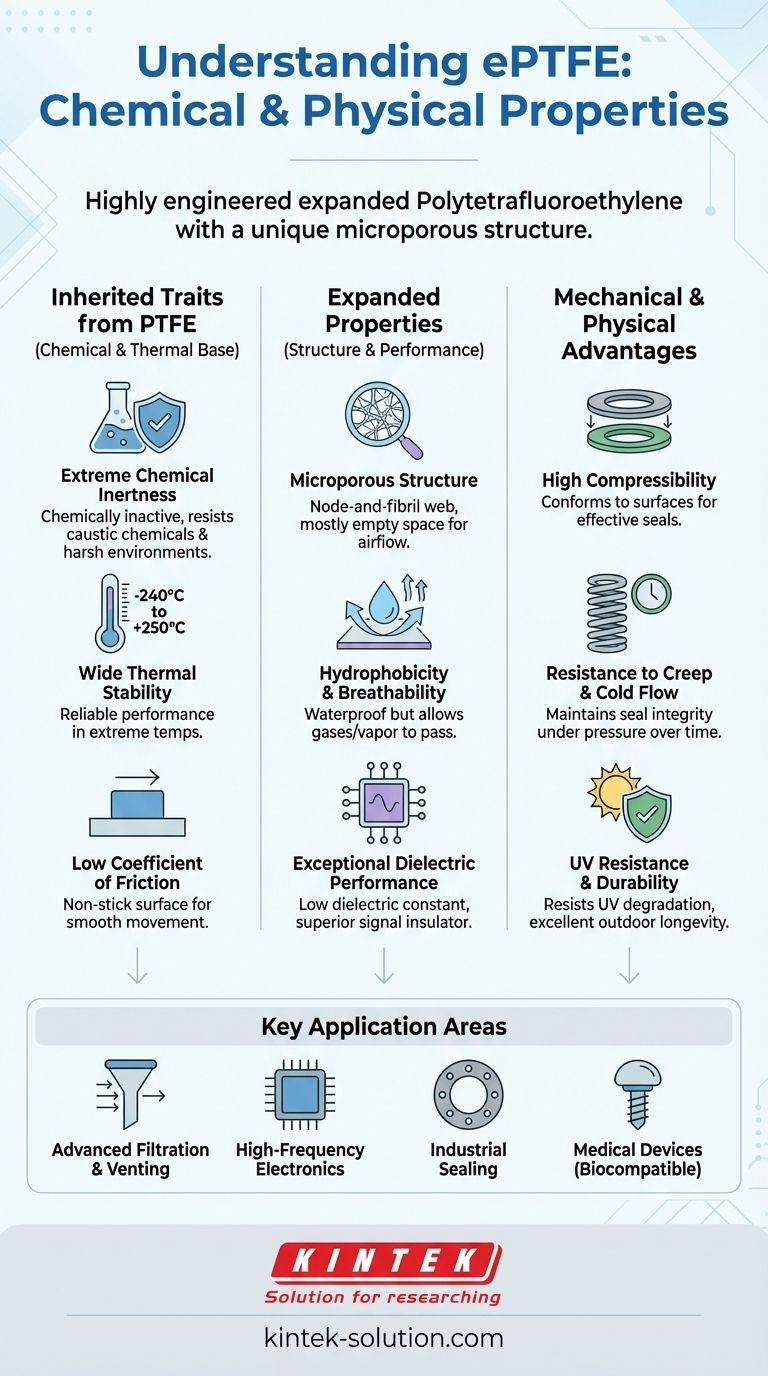

At its core, expanded Polytetrafluoroethylene (ePTFE) is a highly engineered material that retains the exceptional chemical inertness and temperature resistance of standard PTFE while adding a unique microporous structure. This structure gives it remarkable properties, including controlled airflow, a low dielectric constant, and an extremely low coefficient of friction, making it suitable for a vast range of demanding applications.

The defining characteristic of ePTFE is not just the base polymer but its physical form: a web-like, microporous structure. This transformation from a solid material into a porous one unlocks a unique combination of properties that solid PTFE cannot offer.

The Foundation: Inherited Traits from PTFE

To understand ePTFE, we must first recognize the powerful base material from which it is derived: Polytetrafluoroethylene (PTFE). ePTFE inherits and leverages several of PTFE's most valuable characteristics.

Extreme Chemical Inertness

ePTFE is chemically inactive and exhibits excellent resistance to even the most caustic chemicals. This makes it a premier choice for use in harsh chemical processing and medical environments where reactivity is unacceptable.

Wide Thermal Stability

The material can operate reliably across an exceptionally broad temperature range, from a cryogenic -240°C to a high of +250°C. This stability, combined with its non-flammable nature, ensures performance in extreme conditions.

Low Coefficient of Friction

PTFE's famously non-stick surface is retained in ePTFE. This results in an extremely low coefficient of friction, which is valuable in applications requiring smooth movement or easy-release surfaces.

The Transformation: How Expansion Creates Unique Properties

The "e" in ePTFE stands for "expanded," a process that transforms solid PTFE fine powder into a three-dimensional, web-like material with billions of microscopic pores. This physical change is the key to its enhanced capabilities.

The Microporous Structure

The expansion process creates a node-and-fibril structure that is mostly empty space. This microporous nature is fundamental to its use in applications requiring airflow, such as high-performance filters and vents.

Hydrophobicity and Breathability

While the material is hydrophobic (water-resistant) at low pressures, the pores allow gases like air and water vapor to pass through. This unique combination of being waterproof yet breathable is critical for protective vents and advanced textiles.

Exceptional Dielectric Performance

The porous structure, which incorporates a significant amount of air, dramatically lowers the material's dielectric constant. This makes ePTFE a superior insulator for high-frequency cables and complex electronics, where minimizing signal loss is critical.

Key Mechanical and Physical Advantages

Beyond its chemical and thermal stability, ePTFE's structure provides distinct mechanical benefits that solve common engineering challenges.

High Compressibility

ePTFE is highly compressible and can conform to irregular surfaces, making it an excellent sealing material. It creates a tight seal without significant force.

Resistance to Creep and Cold Flow

Unlike many polymers that deform under sustained pressure (a phenomenon known as creep or cold flow), ePTFE is highly resistant. This ensures that seals and gaskets made from it maintain their integrity over long periods.

UV Resistance and Durability

The material is inherently resistant to degradation from UV radiation. This, combined with its resistance to mechanical wear, gives it excellent longevity in outdoor and other demanding environments.

Understanding the Trade-offs and Design Considerations

While versatile, ePTFE is an engineered material whose properties must be matched to the application. Understanding its nuances is key to successful implementation.

Porosity vs. Strength

The degree of expansion directly impacts porosity and density. A more expanded, porous material will have a lower dielectric constant and better breathability but may have lower tensile strength than a less expanded, denser version.

Modifiable Properties

The manufacturing process allows for the modification of key properties. The material's stiffness, hardness, and even surface energy can be tailored to meet the precise needs of a specific application.

Biocompatibility for Medical Use

ePTFE is not only chemically inert but also biocompatible, meaning it does not cause adverse reactions in the human body. This has made it a cornerstone material for medical implants, sutures, and surgical meshes.

Making the Right Choice for Your Application

Selecting the right grade and form of ePTFE requires aligning its unique properties with your primary goal.

- If your primary focus is advanced filtration or venting: Leverage its hydrophobic, non-stick, and microporous structure for high-efficiency particulate capture and reliable airflow.

- If your primary focus is high-frequency electronics: Prioritize its exceptionally low dielectric constant and high thermal stability to ensure signal integrity and component reliability.

- If your primary focus is industrial sealing: Depend on its chemical inertness, compressibility, and resistance to creep to create durable, long-lasting gaskets in harsh environments.

- If your primary focus is medical devices: Rely on its proven biocompatibility and chemical inertness for safe, stable performance in implants and other critical applications.

Ultimately, ePTFE's value lies in its engineered versatility, offering a solution where other materials fail to perform.

Summary Table:

| Key Property | Key Characteristic | Primary Benefit |

|---|---|---|

| Chemical Inertness | Resists even the most caustic chemicals. | Ideal for harsh chemical and medical environments. |

| Microporous Structure | Web-like, node-and-fibril construction. | Enables controlled breathability, filtration, and venting. |

| Thermal Stability | Performs from -240°C to +250°C. | Reliable operation in extreme temperature conditions. |

| Low Dielectric Constant | Excellent insulator due to air-filled pores. | Critical for high-frequency electronics and cables. |

| Biocompatibility | Safe for use within the human body. | Foundational material for medical implants and devices. |

| High Compressibility | Conforms to irregular surfaces under low force. | Creates effective, long-lasting seals and gaskets. |

Leverage the Power of ePTFE for Your Most Demanding Applications

KINTEK specializes in the precision manufacturing of high-performance PTFE and ePTFE components, including custom seals, liners, labware, and complex fabricated parts. Whether you are developing a new medical device, a critical semiconductor tool, or an industrial sealing solution, our expertise in material science and custom fabrication ensures you get a component that perfectly matches your application's requirements—from initial prototypes to high-volume production.

Ready to solve your design challenge with ePTFE? Contact our engineering team today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs