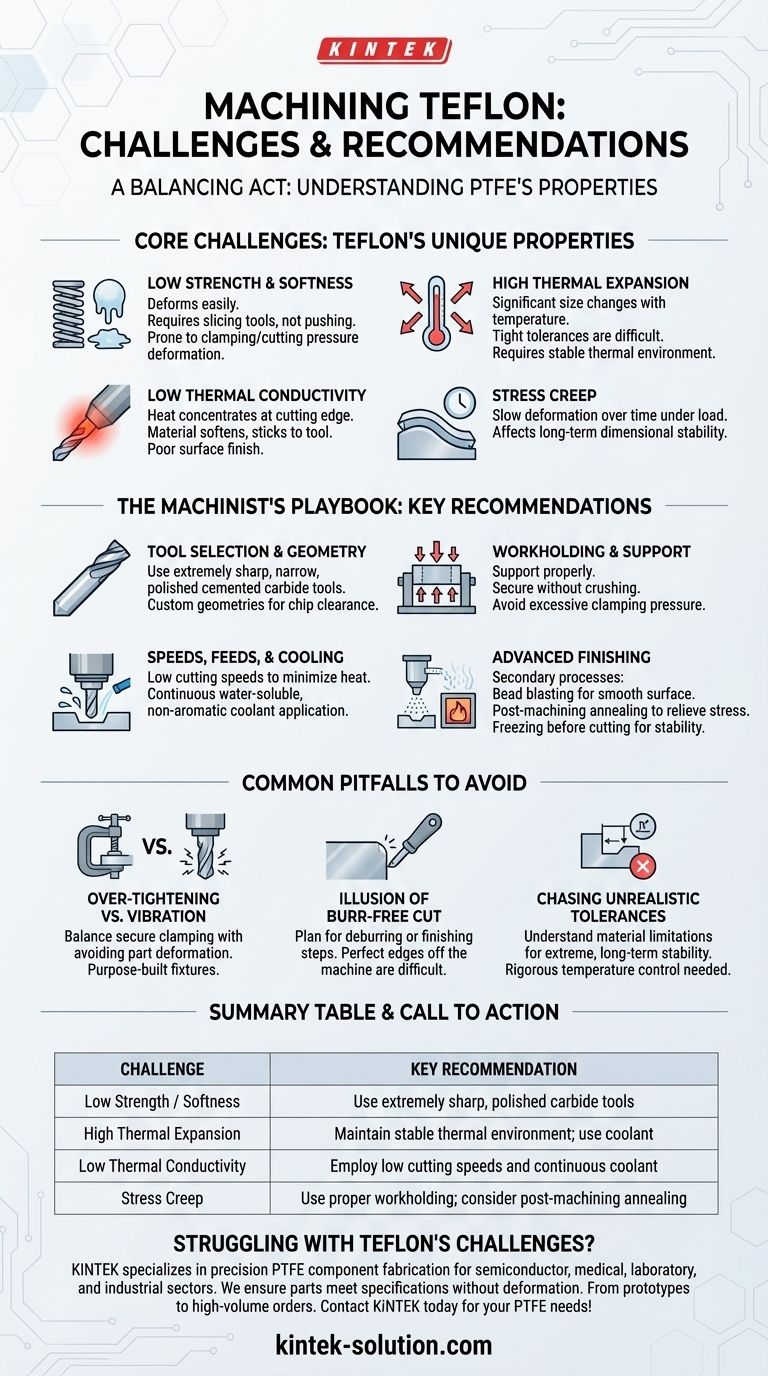

Machining Teflon (PTFE) is a balancing act between its apparent softness and its hidden challenges. The primary difficulties stem from its low strength, high coefficient of thermal expansion, and tendency to deform under pressure. Recommendations center on using exceptionally sharp tools, managing heat with proper coolants and low cutting speeds, and securing the workpiece without causing distortion.

The core challenge isn't cutting Teflon, but controlling it. Success hinges on managing its inherent instability—its tendency to deform under pressure, expand with heat, and creep over time—by using exceptionally sharp tools, light cutting forces, and rigorous thermal management.

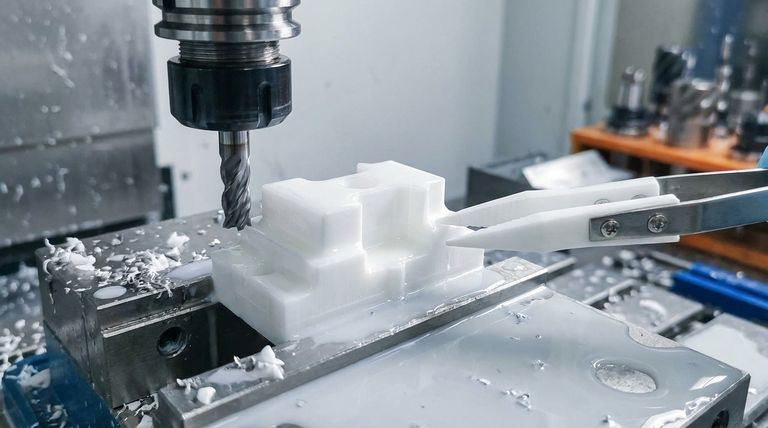

The Core Challenge: Understanding Teflon's Properties

To machine Teflon effectively, you must first respect its unique material characteristics. These properties are the root cause of nearly every challenge encountered during the machining process.

Low Strength and High Softness

Teflon has very low strength and is exceptionally soft compared to metals or even other plastics like Nylon.

This means it deforms easily under both clamping and cutting pressure. It requires tools that slice cleanly rather than push material away.

High Thermal Expansion

Teflon expands and contracts significantly with even minor temperature changes. This high coefficient of thermal expansion is a primary obstacle to achieving tight tolerances.

A part measured at one temperature may be out of spec at another. Maintaining a stable thermal environment is critical for precision work.

Low Thermal Conductivity

Teflon is an excellent insulator, which means it doesn't dissipate heat well.

During machining, heat concentrates at the cutting edge instead of being carried away in the chip. This can cause the material to soften, stick to the tool, and degrade the surface finish.

Stress Creep

Teflon exhibits stress creep, meaning it will slowly deform over time when under a constant load.

This can affect the long-term dimensional stability of a finished part, especially if it was held under pressure during machining.

The Machinist's Playbook: Key Recommendations

Based on these properties, a clear set of best practices emerges. Following these guidelines mitigates the most common problems and leads to predictable, high-quality results.

Tool Selection and Geometry

The right tool is non-negotiable. Standard tooling for metals will produce poor results.

Use extremely sharp, narrow tools, preferably made from cemented carbide. Polished surfaces on the tool reduce friction and prevent material from sticking. Custom tool geometries that enhance chip clearance are highly effective.

Workholding and Support

How you hold the workpiece is as important as how you cut it.

The material must be supported properly and clamped securely enough to prevent vibration or movement. However, excessive clamping pressure will cause the part to deform, leading to inaccurate cuts.

Speeds, Feeds, and Cooling

Managing heat is a primary objective.

Use low cutting speeds to minimize heat generation. A continuous application of a non-aromatic, water-soluble coolant is highly recommended to cool both the workpiece and the tool, improving surface finish and tool life.

Advanced Finishing and Stabilization

For the highest quality results, secondary processes may be necessary.

Bead blasting can be used to create a smoother, more uniform surface finish and remove minor burrs. In some cases, post-machining annealing (a controlled heating and cooling process) can relieve internal stresses built up during machining. For extreme stability, some machinists temporarily freeze the material before cutting to reduce deformation.

Common Pitfalls to Avoid

Even with the right strategy, several common mistakes can compromise the quality of the final part. Being aware of these trade-offs is crucial.

Over-tightening vs. Vibration

This is the central dilemma of workholding. Clamping too tightly will crush or deform the part, while clamping too loosely will cause tool chatter and a poor surface finish.

The solution requires purpose-built fixtures that provide broad support with minimal, evenly distributed pressure.

The Illusion of a Burr-Free Cut

Due to Teflon's softness, achieving a perfectly crisp, burr-free edge is extremely difficult.

Expect to perform a deburring or finishing step. Plan for this in your process rather than trying to achieve a flawless finish directly off the machine.

Chasing Unrealistic Tolerances

Given its thermal expansion and stress creep, Teflon is not the ideal material for components requiring extreme, long-term dimensional stability.

Understand the material's limitations. If you must hold a tight tolerance, it requires rigorous temperature control throughout the entire process, from storage to final inspection.

Making the Right Choice for Your Goal

Your specific approach should be tailored to the primary objective of the part you are creating.

- If your primary focus is high precision: Prioritize absolute thermal stability in your shop and consider post-machining annealing to ensure dimensional accuracy.

- If your primary focus is surface finish: Use polished carbide tools, a constant flood of coolant, and be prepared to use a post-processing method like bead blasting.

- If your primary focus is production efficiency: Invest in custom workholding that allows for secure, repeatable clamping without deformation, and use high-quality carbide tools to maximize tool life.

By treating Teflon with the finesse it requires, you can transform its challenging properties into predictable and successful outcomes.

Summary Table:

| Challenge | Key Recommendation |

|---|---|

| Low Strength / Softness | Use extremely sharp, polished carbide tools |

| High Thermal Expansion | Maintain stable thermal environment; use coolant |

| Low Thermal Conductivity | Employ low cutting speeds and continuous coolant |

| Stress Creep | Use proper workholding; consider post-machining annealing |

Struggling with Teflon's unique machining challenges? KINTEK specializes in precision PTFE component fabrication for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance required to machine Teflon effectively, ensuring your parts meet exact specifications without deformation. Our expertise in custom fabrication—from prototypes to high-volume orders—guarantees superior results. Let us handle the complexities so you get reliable, high-performance components. Contact KINTEK today to discuss your PTFE project needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry