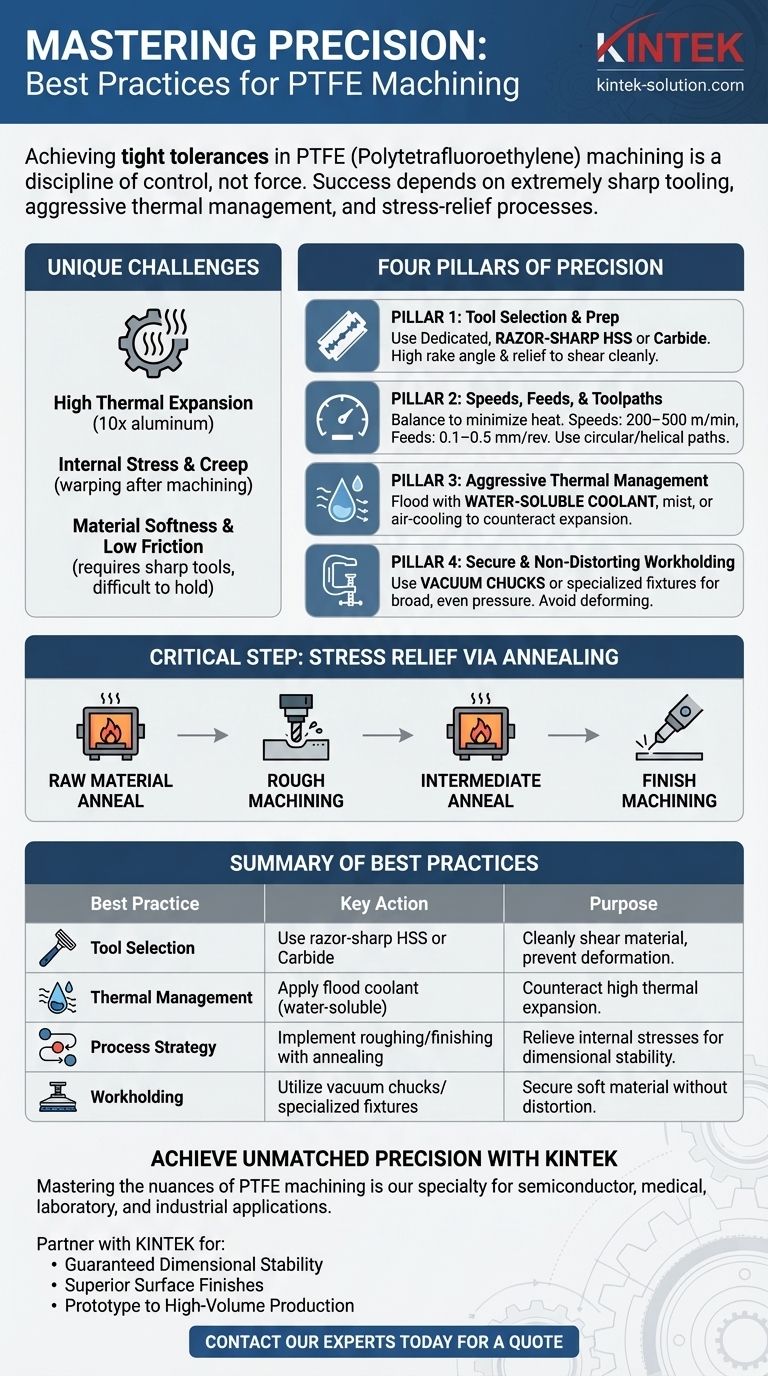

Achieving tight tolerances in Polytetrafluoroethylene (PTFE) machining is a discipline of control, not force. Success depends on a combination of extremely sharp tooling, aggressive thermal management to counteract the material's high expansion rate, and stress-relief processes like annealing to ensure dimensional stability. The key is to manage the material's inherent instability at every stage of the process.

The core challenge of machining PTFE isn't its hardness, but its softness and instability. Every best practice is designed to overcome its high thermal expansion, internal stresses, and tendency to deform under cutting pressure.

Understanding PTFE's Unique Machining Challenges

Before applying techniques, you must understand the properties that make PTFE (often known by the brand name Teflon) notoriously difficult to machine with precision.

High Thermal Expansion

PTFE has a coefficient of thermal expansion roughly ten times that of aluminum. This means even a small amount of heat generated during cutting causes the material to expand significantly.

A part machined to perfect specifications while warm will shrink and fall out of tolerance as it cools to ambient temperature.

Internal Stress and Creep

The process used to create PTFE stock shapes (like rods or sheets) leaves behind internal stresses. As you machine material away, you release these stresses unevenly.

This release can cause the material to warp, bow, or distort, often hours or even days after the machining is complete. This phenomenon is known as stress creep.

Material Softness and Low Friction

PTFE is a soft material that requires exceptionally sharp tools to achieve a clean shearing action. A dull tool will not cut, but rather push or plow the material, leading to a poor surface finish and dimensional inaccuracies.

Its low coefficient of friction (slipperiness) also makes it difficult to hold securely without deforming it.

The Pillars of Precision PTFE Machining

To counteract these challenges, your machining process must be built on four distinct pillars.

Pillar 1: Tool Selection and Preparation

The single most important factor is the sharpness of your cutting tool. A sharp edge cleanly shears the material instead of deforming it.

Use dedicated tools made from High-Speed Steel (HSS) or Carbide. The tool must be ground to a razor-sharp edge with a high rake angle and significant relief to prevent rubbing.

Pillar 2: Strategic Speeds, Feeds, and Toolpaths

You must balance speeds and feeds to minimize heat generation while ensuring a clean cut.

Start with cutting speeds around 200–500 m/min and feed rates of 0.1–0.5 mm/rev. These are starting points; adjust based on the specific part geometry and machine rigidity.

Employ circular or helical toolpaths to minimize tool engagement and vibration. Avoid aggressive, full-width cuts that introduce excessive stress and heat into the workpiece.

Pillar 3: Aggressive Thermal Management

Controlling temperature is non-negotiable. The goal is to remove heat as quickly as it is generated.

A generous flood of water-soluble coolant is highly effective. For certain applications, mist systems or direct air-cooling can also work to prevent heat buildup and clear chips.

Pillar 4: Secure and Non-Distorting Workholding

Your fixture must hold the PTFE workpiece securely to prevent any movement during machining.

Use specialized fixtures or vacuum chucks that provide broad, even clamping pressure. This prevents the soft material from being crushed or distorted, which would ruin the final dimensions.

A Critical Step: Stress Relief via Annealing

For the highest precision work, machining alone is not enough. Annealing is a heat treatment process that normalizes the material by relieving the internal stresses.

Why Annealing is Necessary

By heating the PTFE to a specific temperature, holding it, and then slowly cooling it, you allow the material's internal structure to relax. This creates a much more stable workpiece that is less likely to warp after machining.

When to Anneal

A common best practice for tight-tolerance parts is a multi-stage process:

- Anneal the raw material stock.

- Perform rough machining, leaving a small amount of material for the final pass.

- Anneal the part again to relieve stresses induced by the roughing operation.

- Perform the final finish machining pass to bring the part to its final dimensions.

Common Pitfalls to Avoid

Mistakes in PTFE machining are common because the required approach is often counter-intuitive compared to working with metals.

Using Dull or Improper Tooling

This is the most frequent error. A tool that feels sharp to the touch may not be sharp enough for PTFE. The result is material smearing, a "gummy" finish, and an inability to hold size.

Ignoring Heat Buildup

Machining PTFE dry without any form of cooling is a recipe for failure. The part will inevitably expand during the cut and be undersized once it cools.

Inadequate Workholding

If the part can shift or vibrate even slightly in the fixture, all other precision efforts are wasted. PTFE's slipperiness makes this a significant risk.

Unrealistic Tolerance Expectations

While tight tolerances are achievable, the inherent properties of PTFE mean there are practical limits. Part design should always account for the material's high thermal expansion and potential for creep.

Making the Right Choice for Your Application

Tailor your approach based on the most critical requirement of the finished part.

- If your primary focus is dimensional stability on complex parts: Prioritize a multi-step process with annealing between the roughing and finishing passes.

- If your primary focus is achieving the best possible surface finish: Use extremely sharp, dedicated tooling with a constant, high-volume supply of coolant.

- If your primary focus is consistency across a production run: Implement strict environmental temperature controls and use high-precision inspection tools like a CMM to validate your setup and process.

Mastering these principles transforms the challenge of machining PTFE from a frustrating art into a repeatable science.

Summary Table:

| Best Practice | Key Action | Purpose |

|---|---|---|

| Tool Selection | Use razor-sharp HSS or Carbide tools | Cleanly shear material, prevent deformation |

| Thermal Management | Apply flood coolant (e.g., water-soluble) | Counteract high thermal expansion |

| Process Strategy | Implement roughing/finishing with annealing | Relieve internal stresses for dimensional stability |

| Workholding | Utilize vacuum chucks or specialized fixtures | Secure soft material without distortion |

Achieve Unmatched Precision in Your PTFE Components with KINTEK

Mastering the nuances of PTFE machining is our specialty. For semiconductor, medical, laboratory, and industrial applications where precision is non-negotiable, KINTEK delivers.

We leverage the exact best practices outlined here—from aggressive thermal management to strategic stress-relief annealing—to manufacture high-performance PTFE seals, liners, labware, and custom components that meet your most demanding specifications.

Partner with KINTEK for:

- Guaranteed Dimensional Stability: Our controlled processes ensure your parts remain in tolerance, overcoming PTFE's inherent challenges.

- Superior Surface Finishes: Achieve the clean, functional surfaces your application requires.

- Prototype to High-Volume Production: We scale our precision to your needs, ensuring consistency across every order.

Let's engineer your solution. Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems