At its core, glass microsphere-filled PTFE is used in applications demanding high wear resistance and compressive strength, where pure PTFE would fail. The most common application is in components like hydraulic piston rings, valve seats, and bearings that operate under significant mechanical load.

The fundamental purpose of adding glass microspheres to PTFE is to solve its inherent mechanical weaknesses—primarily its tendency to creep and wear—while preserving its exceptionally low friction and chemical inertness.

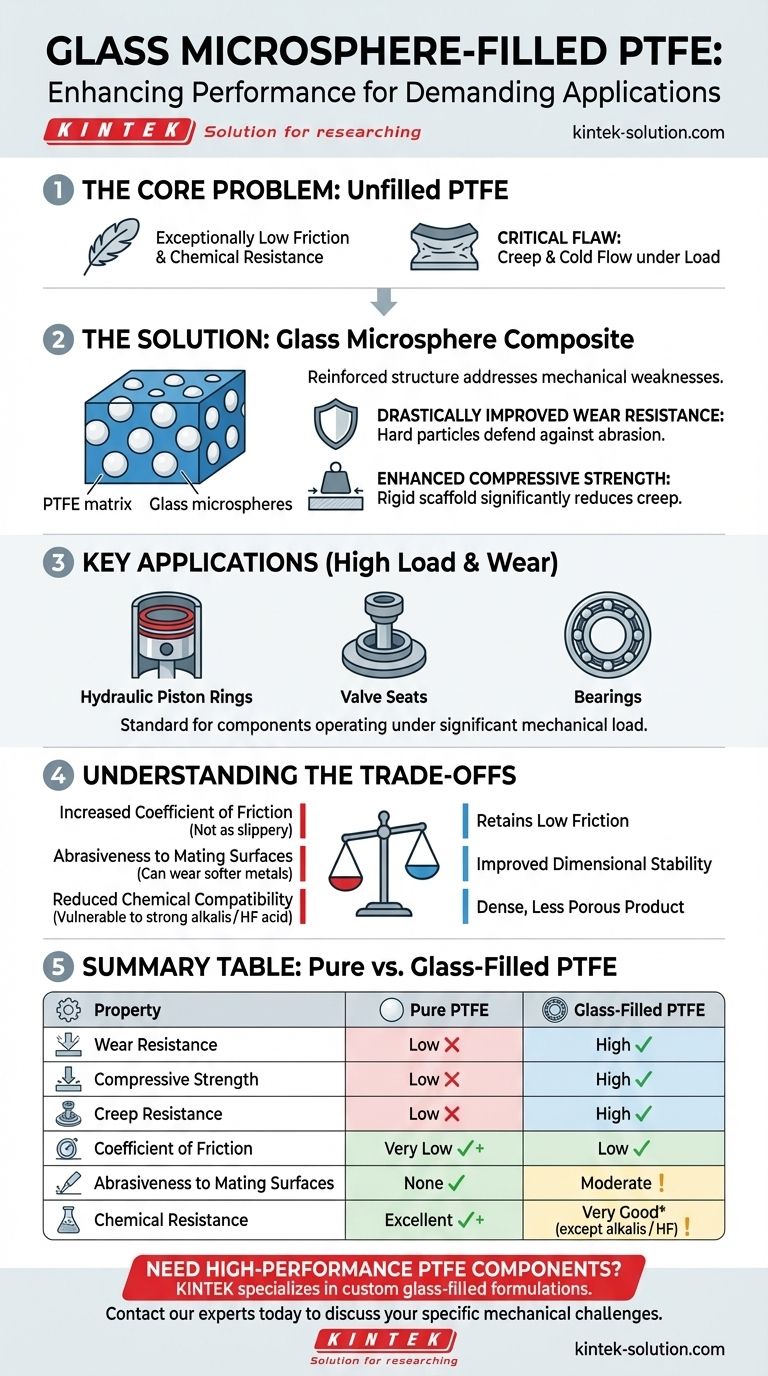

The Core Problem with Unfilled PTFE

To understand the value of glass fillers, we must first recognize the limitations of pure Polytetrafluoroethylene (PTFE). While known for its remarkable properties, it is not a perfect engineering material on its own.

### Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, making it an ideal choice for applications where sliding and surface wear are concerns.

### Excellent Chemical and Thermal Resistance

It remains stable and resistant to nearly all solvents and chemicals across a wide temperature range, typically from -70°C to 260°C.

### The Critical Flaw: Creep and Cold Flow

The major drawback of pure PTFE is its mechanical weakness. Under a sustained load, especially at elevated temperatures, it will deform permanently in a process known as creep or cold flow. This makes it unsuitable for many load-bearing structural or sealing applications.

How Glass Microspheres Transform PTFE

Adding glass microspheres as a filler creates a composite material that directly addresses PTFE's mechanical deficiencies, significantly expanding its range of use.

### Drastically Improved Wear Resistance

The hard glass particles distributed throughout the softer PTFE matrix provide a robust defense against abrasive wear. This composite structure protects the PTFE from being worn away in dynamic applications.

This is precisely why glass-filled PTFE is a standard material for hydraulic piston rings and other demanding seals.

### Enhanced Compressive Strength and Creep Resistance

The microspheres act as a rigid internal scaffold. When a load is applied, the spheres bear a significant portion of the stress, which dramatically reduces the tendency of the PTFE to creep and deform.

Higher concentrations of glass filler directly correlate to higher compressive strength, making the material more durable under heavy loads.

### Reduced Porosity and Improved Stability

The manufacturing process for glass-filled PTFE, often involving inert gas sintering, results in a denser, less porous final product. This contributes to its improved dimensional stability and resistance to deformation over time.

Understanding the Trade-offs

While glass fillers offer significant advantages, they also introduce important trade-offs that every engineer must consider. No material choice is without compromise.

### Increased Coefficient of Friction

Adding hard particles to the super-slick PTFE surface will inevitably increase its coefficient of friction. While the composite remains a low-friction material, it is not as slippery as its unfilled counterpart.

### Abrasiveness to Mating Surfaces

The hardness of the glass filler can cause wear on softer mating surfaces, such as aluminum or certain stainless steels. This is a critical design consideration, as the filled PTFE part could prematurely damage other components in an assembly.

### Reduced Chemical Compatibility

While glass is highly inert, it is not as universally resistant as PTFE. It can be attacked by strong alkaline solutions and hydrofluoric acid, creating a potential failure point that does not exist with pure PTFE.

Making the Right Choice for Your Application

Selecting the correct material requires aligning the properties of the PTFE compound with the specific demands of your application.

- If your primary focus is dynamic seals under high pressure: Glass-filled PTFE is an excellent choice for its superior wear and creep resistance, making it ideal for piston rings and valve seats.

- If your primary focus is the absolute lowest friction: Unfilled PTFE is the superior option, provided the mechanical loads are low enough to avoid creep.

- If you are working with soft or sensitive mating surfaces: Be cautious with glass-filled PTFE due to its abrasive nature and consider a compound with a non-abrasive filler like graphite.

By understanding these property enhancements and their associated trade-offs, you can leverage glass-filled PTFE to solve mechanical challenges that pure PTFE cannot.

Summary Table:

| Property | Pure PTFE | Glass-Filled PTFE |

|---|---|---|

| Wear Resistance | Low | High |

| Compressive Strength | Low | High |

| Creep Resistance | Low | High |

| Coefficient of Friction | Very Low | Low |

| Abrasiveness to Mating Surfaces | None | Moderate |

| Chemical Resistance | Excellent | Very Good (except strong alkales/HF acid) |

Need a high-performance PTFE component that can handle heavy loads?

KINTEK specializes in manufacturing precision PTFE components, including custom glass-filled formulations, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts deliver superior wear resistance and compressive strength, from prototype to high-volume production.

Contact our experts today to discuss how our custom PTFE solutions can solve your specific mechanical challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts