The primary advantage of a PTFE encapsulated O-ring is its ability to combine the exceptional chemical and temperature resistance of PTFE with the flexibility and sealing force of a traditional elastomer. This hybrid design creates a seal that can withstand extremely harsh environments where a standard O-ring would quickly fail, often at a lower cost than exotic compounds like perfluoroelastomers (FFKM).

A PTFE encapsulated O-ring is best understood as a high-performance shield for a standard elastomer. It delivers the near-universal chemical inertness of solid PTFE without sacrificing the essential flexibility required for reliable sealing in demanding applications.

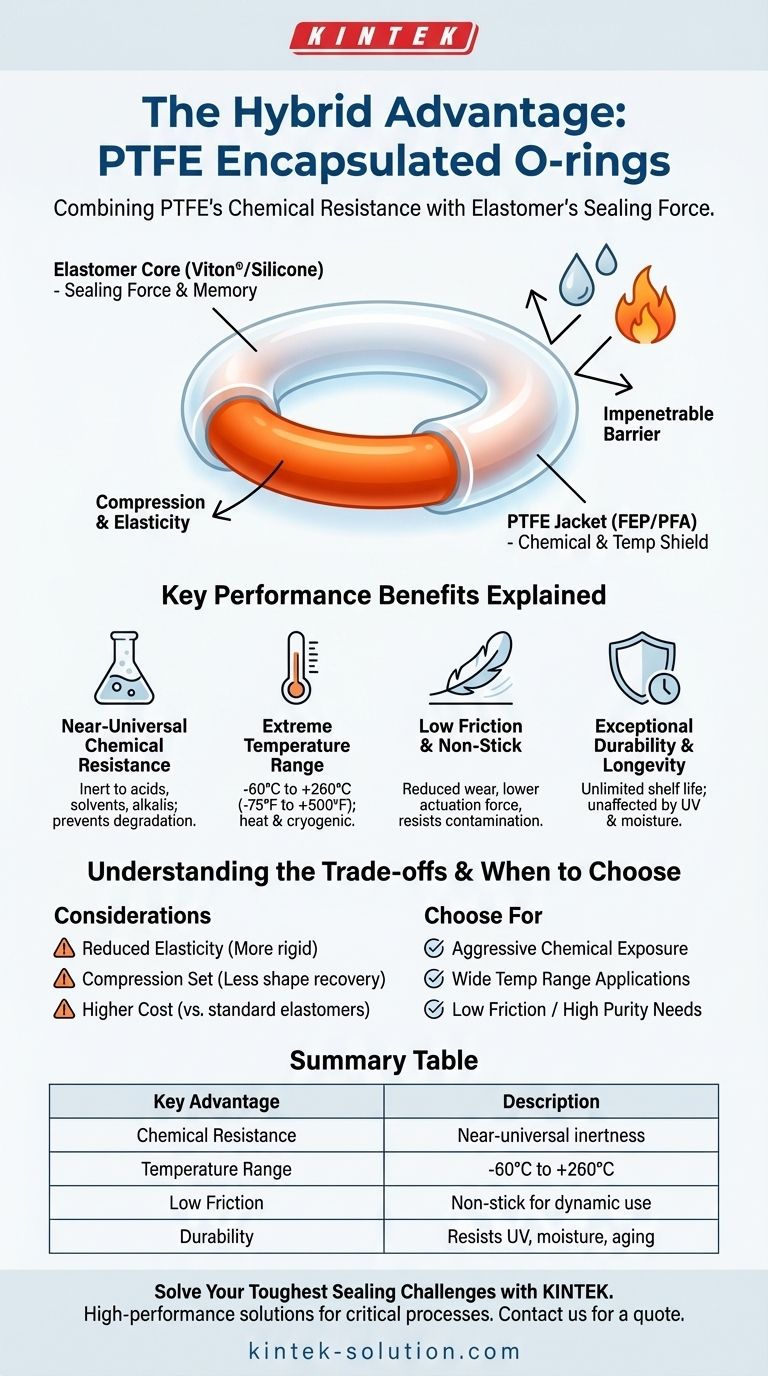

The Core Advantage: A Hybrid Design

The unique benefits of this O-ring stem directly from its two-part construction. Understanding this structure is key to understanding its performance.

How Encapsulation Works

A PTFE encapsulated O-ring consists of a core of elastic material, like Viton® (FKM) or Silicone (VMQ). This core is completely enclosed within a seamless jacket of Polytetrafluoroethylene (PTFE), typically FEP or PFA resins.

The Elastomer Core: Providing the Sealing Force

The inner elastomer core provides the O-ring with its "memory" and elasticity. This allows it to compress, conform to gland surfaces, and maintain a consistent sealing force over time.

The PTFE Jacket: A Protective Shield

The outer PTFE jacket acts as an impenetrable barrier. It is this layer that provides the signature advantages of the seal, protecting the more vulnerable elastomer core from aggressive media.

Key Performance Benefits Explained

This dual-material construction delivers a unique combination of properties that make it a superior choice for specific challenges.

Near-Universal Chemical Resistance

The PTFE jacket is virtually chemically inert. It is impervious to almost all industrial chemicals, including aggressive acids, solvents, and alkalis, preventing the swelling or degradation that would destroy a standard elastomer.

Extreme Temperature Range

These O-rings can operate effectively across a vast temperature spectrum, typically from -60°C to +260°C (-75°F to +500°F). This allows them to function in applications with severe heat or cryogenic conditions.

Low Friction and Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This results in less wear in dynamic applications, reduced actuation force, and a non-stick surface that resists contamination and buildup.

Exceptional Durability and Longevity

The PTFE material does not degrade with age, is unaffected by UV light, and does not swell from moisture absorption. This gives encapsulated O-rings an almost unlimited shelf life and extends their service life in the application.

Understanding the Trade-offs

While powerful, this design is not a universal solution. Its hybrid nature introduces specific limitations that are critical to consider.

Reduced Elasticity

The PTFE jacket is more rigid than a standard elastomer. This means the O-ring is less flexible, requiring more care during installation to avoid kinking or damaging the jacket, which would compromise the seal.

Compression Set Considerations

While the elastomer core provides good compression set resistance, the rigid PTFE jacket does not recover its shape as effectively as a pure elastomer. In applications with high pressure or long-term compression, this can be a factor.

Higher Cost Than Standard Elastomers

PTFE encapsulated O-rings are more expensive than common compounds like Nitrile (Buna-N) or standard Viton®. However, they are often a more economical choice than solid PTFE or exotic perfluoroelastomer (FFKM) O-rings.

When to Choose a PTFE Encapsulated O-ring

This O-ring is a problem-solver for applications where standard seals are inadequate. Base your decision on your most critical performance requirement.

- If your primary focus is aggressive chemical exposure: Choose these O-rings when your media would degrade or destroy standard Viton®, EPDM, or Silicone seals.

- If your primary focus is a very wide temperature range: They are an excellent solution for equipment that experiences both high operational heat and low-temperature shutdowns.

- If your primary focus is low friction or purity: The non-stick, low-friction surface is ideal for dynamic seals, food processing (FDA compliant grades), or semiconductor applications to prevent contamination.

- If your primary focus is preventing seal failure in harsh environments: This O-ring provides a significant reliability upgrade over standard elastomers, reducing downtime and maintenance costs.

By understanding its unique construction, you can leverage the PTFE encapsulated O-ring as a powerful and cost-effective solution for your most demanding sealing challenges.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Resistance | Near-universal inertness to acids, solvents, and alkalis. |

| Temperature Range | Operates from -60°C to +260°C (-75°F to +500°F). |

| Low Friction | Non-stick surface ideal for dynamic applications. |

| Durability & Longevity | Resists UV, moisture, and aging; unlimited shelf life. |

Solve Your Toughest Sealing Challenges with KINTEK

PTFE encapsulated O-rings are a key component in our portfolio of high-performance PTFE solutions. If your application involves aggressive chemicals, extreme temperatures, or requires high-purity, low-friction seals, our team can help.

KINTEK specializes in the precision manufacturing and custom fabrication of PTFE components—from prototypes to high-volume orders—for the semiconductor, medical, laboratory, and industrial sectors. We ensure the reliability and longevity your critical processes demand.

Contact us today to discuss your specific requirements and get a quote: Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F