In a direct comparison, PTFE packing's primary advantages over graphite packing are its superior chemical inertness and its properties as an electrical insulator. It excels in environments with aggressive chemicals, acids, and corrosives where product purity is critical, and its low-friction, non-conductive nature helps protect shafts from scoring and galvanic corrosion.

The choice between PTFE and graphite packing is a classic engineering trade-off. Your decision hinges on whether the application demands PTFE's exceptional chemical resistance and non-contaminating properties or graphite's superior ability to handle extreme temperatures and high shaft speeds.

Fundamental Material Differences

To understand their advantages, it's essential to recognize that PTFE and graphite are fundamentally different materials. This core difference dictates their ideal use cases.

### Origin and Composition

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer, known for its extreme chemical stability. It is a man-made material designed specifically for inertness.

Graphite, by contrast, is an inorganic form of pure carbon. It is a natural material valued for its thermal properties and lubricity.

### Physical Characteristics

PTFE packing is characteristically white and does not transfer color, a critical feature in industries like food processing or pharmaceuticals.

Graphite packing is black and known for its self-lubricating capabilities, allowing it to operate effectively in both wet and dry conditions.

Where PTFE Packing Excels

PTFE's synthetic nature gives it a unique combination of properties that make it the superior choice for specific, demanding applications.

### Unmatched Chemical Resistance

PTFE is virtually immune to attack from almost all chemicals, acids, gases, and corrosive substances. This makes it the default choice for sealing the most aggressive media.

The only notable exception to its chemical resistance is with molten alkali metals.

### Preventing Shaft Wear and Contamination

Because PTFE is non-conductive, it prevents galvanic corrosion between dissimilar metals in a system. Its very low coefficient of friction also minimizes wear and scoring on rotating shafts.

Furthermore, its white, non-staining composition ensures that it will not contaminate the process fluid, which is a non-negotiable requirement in high-purity applications.

Understanding the Trade-offs: Graphite's Strengths

No material is perfect for every situation. To make an informed choice, you must recognize the areas where graphite packing holds a distinct advantage.

### Superior Thermal Performance

Graphite is an excellent thermal conductor. This allows it to dissipate heat away from the shaft, making it far superior for high-temperature services and high-speed rotating equipment.

PTFE, being a poor thermal conductor, can trap heat and is generally not suitable for applications involving extreme temperatures.

### Performance at High Speeds

Graphite's self-lubricating properties and heat dissipation capabilities allow it to perform reliably at higher shaft speeds than PTFE.

The Hybrid Solution: Graphite-Filled PTFE

To bridge the gap between these two materials, manufacturers offer a hybrid solution that combines their strengths.

### Combining Key Properties

Graphite-filled PTFE incorporates up to 25% graphite into the PTFE matrix. This compound material is black in color.

This blend significantly improves wear resistance, lowers the coefficient of friction, and increases temperature resistance compared to pure PTFE, all while maintaining excellent chemical inertness. It offers a balanced choice for general service applications.

Making the Right Choice for Your Application

Your final decision must be driven by the specific demands of the equipment and the process media.

- If your primary focus is sealing aggressive chemicals or ensuring product purity: Pure PTFE packing is the unequivocal choice for its chemical inertness and non-contaminating nature.

- If your primary focus is handling high temperatures or high-speed rotating shafts: Graphite packing is the superior option due to its thermal conductivity and self-lubricating properties.

- If your primary focus is a versatile seal with good chemical and wear resistance: Graphite-filled PTFE offers a balanced, high-performance solution for a wide range of applications.

Ultimately, selecting the correct packing material is crucial for maximizing equipment reliability and operational safety.

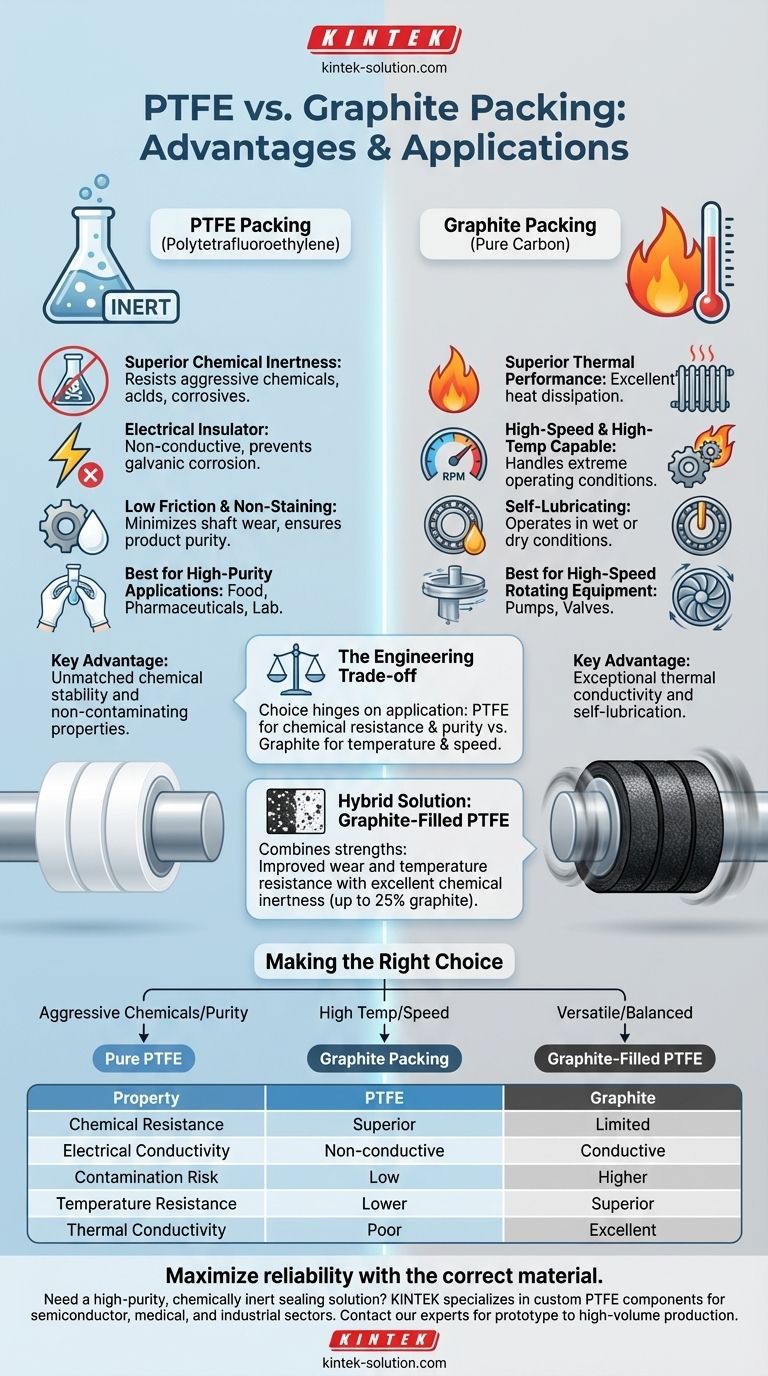

Summary Table:

| Property | PTFE Packing Advantage | Graphite Packing Advantage |

|---|---|---|

| Chemical Resistance | Superior (Inert to most chemicals) | Limited |

| Electrical Conductivity | Non-conductive (Prevents galvanic corrosion) | Conductive |

| Contamination Risk | Low (White, non-staining) | Higher (Black, can stain) |

| Temperature Resistance | Lower | Superior (High-temperature, high-speed) |

| Thermal Conductivity | Poor (Can trap heat) | Excellent (Dissipates heat) |

Need a high-purity, chemically inert sealing solution?

At KINTEK, we specialize in precision manufacturing of custom PTFE components, including seals and packing, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates reliably with maximum chemical resistance and zero contamination risk.

Let us provide the perfect PTFE solution for your application: Contact our experts today to discuss your requirements from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How is PTFE used in industrial processes? Maximize Safety and Efficiency